Real-time control system and method for depth simulator

A real-time control system, deep simulator technology, applied in general control systems, control/regulation systems, simulators, etc., can solve problems such as non-real-time operation, system instability, and low control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

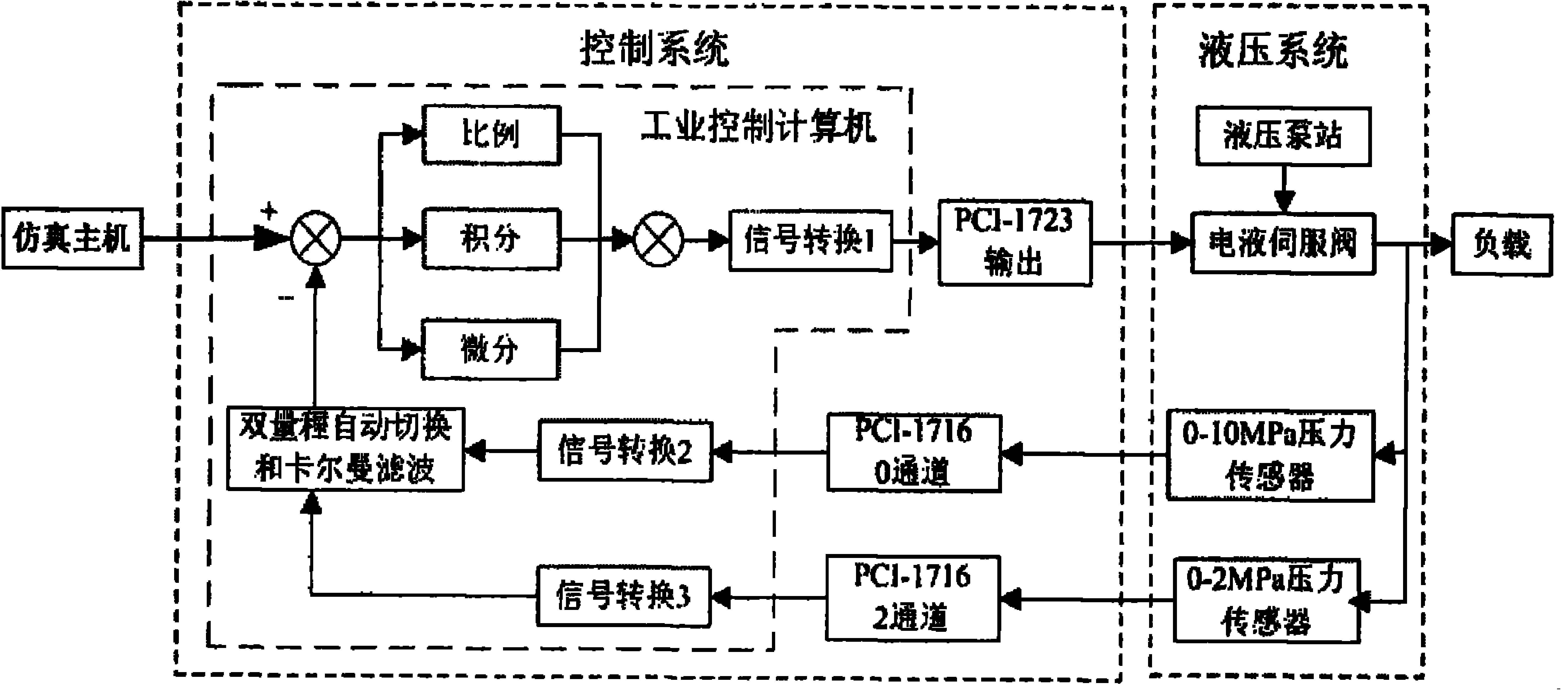

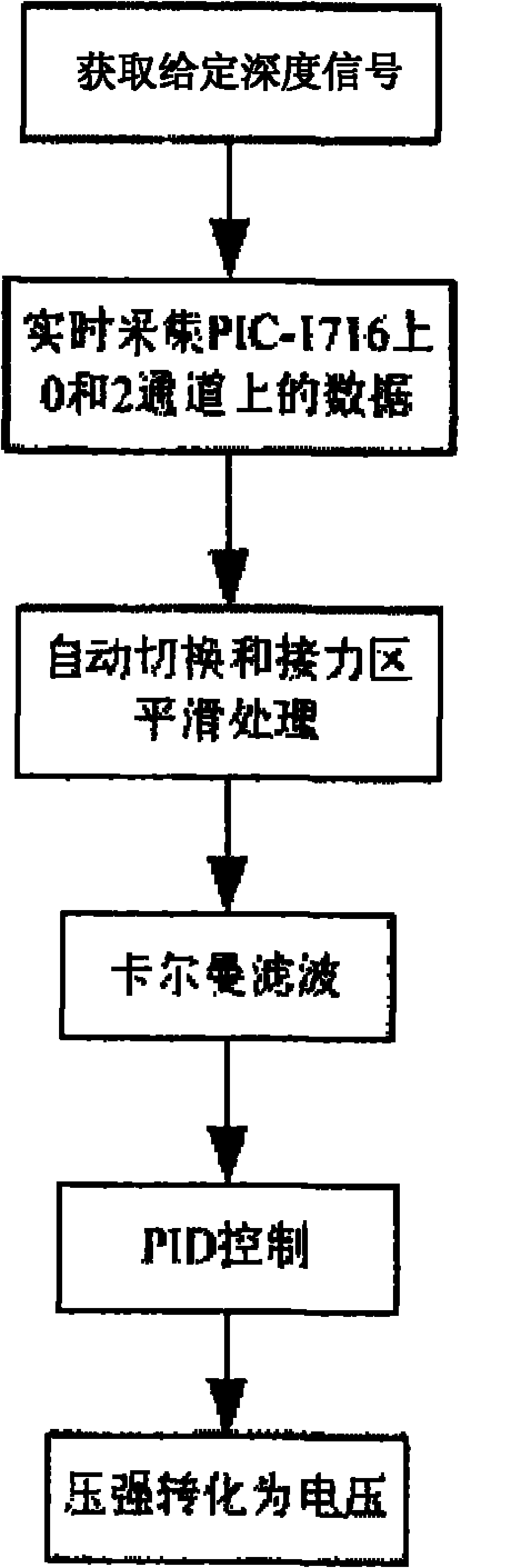

[0038] Such as figure 1 As shown, the present invention includes two parts, a control system and a hydraulic system, wherein the control system is composed of an industrial control computer, a PCI-1716 data acquisition card and a PCI-1723 data output card, etc.; the hydraulic system is composed of a console and a hydraulic pump station. The structure diagram of the system is as follows figure 1 As shown, the functions of each module are as follows:

[0039] a) The hydraulic pump station provides a stable oil source to the pressure chamber of the servo valve;

[0040] b) The console includes electro-hydraulic servo valves and dual-range pressure sensors, etc., which are mainly used to convert electrical signals to pressure signals;

[0041] c) PCI-1716 is a 16-bit 16-channel multi-function data acquisition card, in which channel 0 is connected to the 0-10MPa pressure sensor for obtaining the voltage signal representing the depth fed back by the large-range sensor, and channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com