Heat treatment method of mining scraper

A heat treatment method and scraper technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of ineffective guarantee of parts quality, ineffective implementation of process parameters, high labor intensity, etc., and achieve labor intensity reduction, The distribution of hardened layer is reasonable and the effect of improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

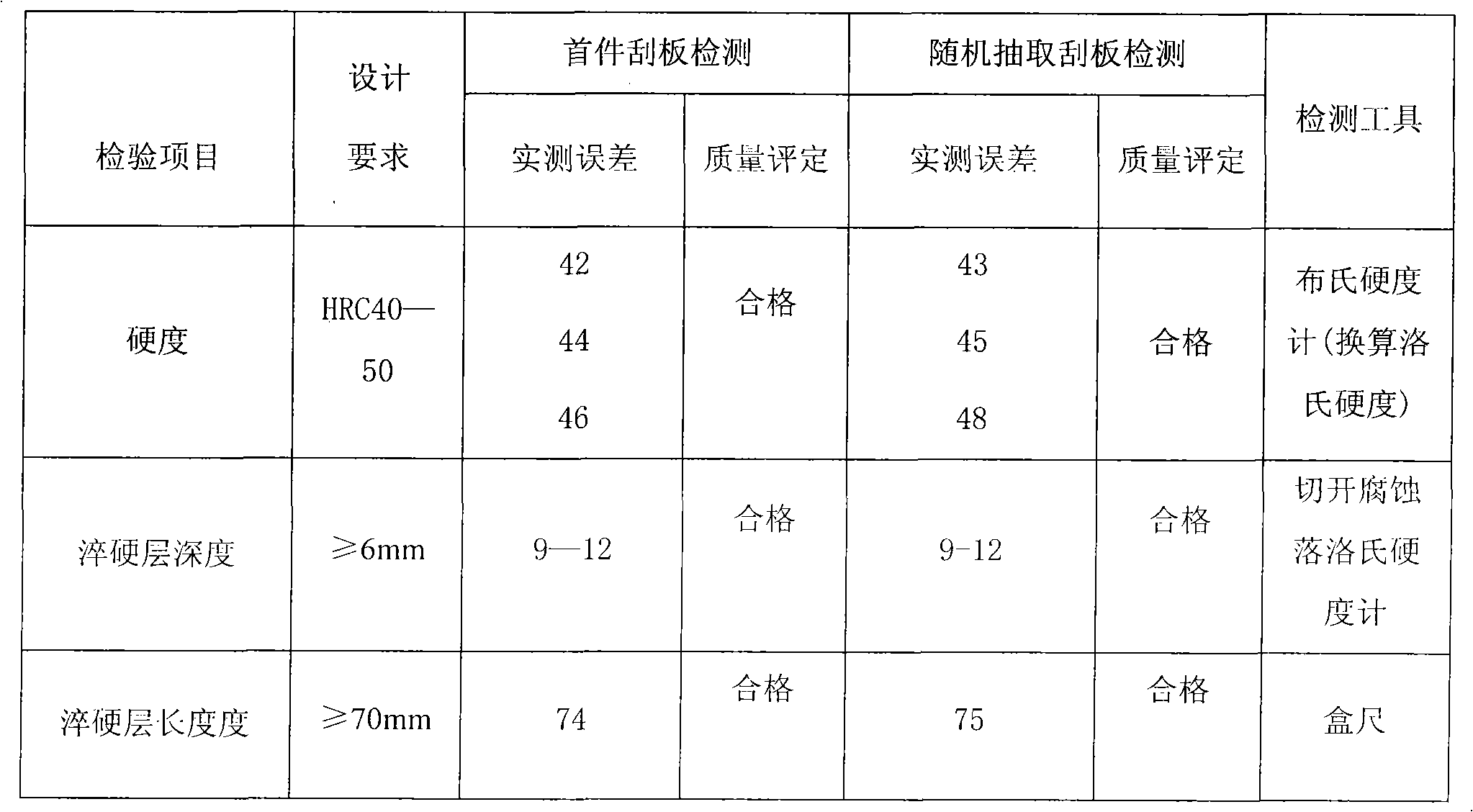

Embodiment 1

[0010] Scraper with a length of 800mm, transfer to the heat treatment device, call up the 800mm scraper quenching program, run the machine dry once, check whether the induction coil and water spray ring are leaking, clamp 4 scraper parts at a time, turn on the power, and execute this program. The conveyor belt of the machine tool moves, and the scraper reaches the induction coil area at a speed of 0.04m / s. The scraper starts to heat for 200 seconds. At this time, the temperature at both ends of the scraper reaches 900℃, and the scraper reaches again at a speed of 0.04m / s In the spray area, the spray ring is opened immediately, and the two ends of the scraper are quickly cooled. The cooling time is 70 seconds. After cooling, the spray ring is closed and the scraper reaches the unloading area for unloading. When the plate reaches the unloading area for unloading, the second scraper enters the induction coil to heat, repeat the above action, and complete the continuous quenching pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com