Silencer Diamond Saw Blade

The technology of diamond saw blade and diamond cutter head is applied in the field of sound-absorbing diamond saw blade, which can solve the problems of physical and mental health injury of construction workers, insignificant noise reduction effect, reduction in the strength of the saw blade substrate, etc., so as to avoid safety accidents and resist bending. High strength and comfort-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

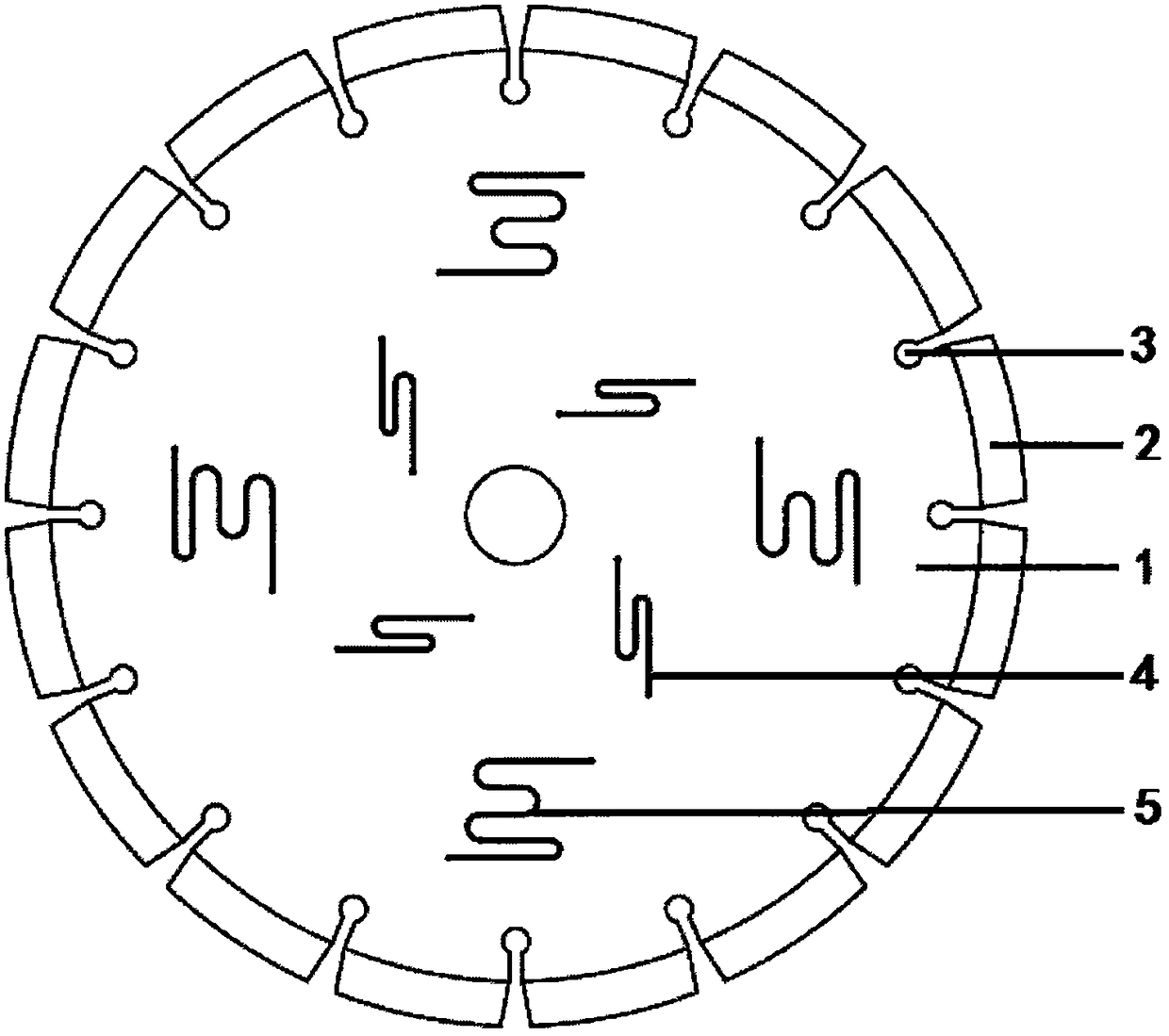

[0020] The sound-absorbing diamond saw blade of the present embodiment comprises a circular steel substrate and 16 diamond cutter heads formed at the end of the circular steel substrate. Flutes. Four first sound-absorbing grooves are evenly distributed at a first distance from the center of the circular base body, and four second sound-absorbing grooves are evenly distributed at a second distance from the center of the circular base body; the second distance is twice the first distance, and the length of the second silencer is twice the length of the first silencer. The shapes of the first and second sound-absorbing grooves include straight lines parallel to each other and smooth curves between adjacent straight lines, and both ends of the first and second sound-absorbing grooves are provided with end blind holes. The cross-sections of the first and second sound-absorbing grooves are both semicircular, and the maximum width thereof is 0.5mm. The first and second sound-absorbi...

Embodiment 2

[0022] The sound-absorbing diamond saw blade of the present embodiment comprises a circular steel substrate and 16 diamond cutter heads formed at the end of the circular steel substrate. Flutes. Four first sound-absorbing grooves are evenly distributed at a first distance from the center of the circular base body, and four second sound-absorbing grooves are evenly distributed at a second distance from the center of the circular base body; the second distance is twice the first distance, and the length of the second silencer is twice the length of the first silencer. The shapes of the first and second sound-absorbing grooves include straight lines parallel to each other and smooth curves between adjacent straight lines, and both ends of the first and second sound-absorbing grooves are provided with end blind holes. The cross-sections of the first and second sound-absorbing grooves are both U-shaped, and their maximum width is 0.5mm, and the first and second sound-absorbing gro...

Embodiment 3

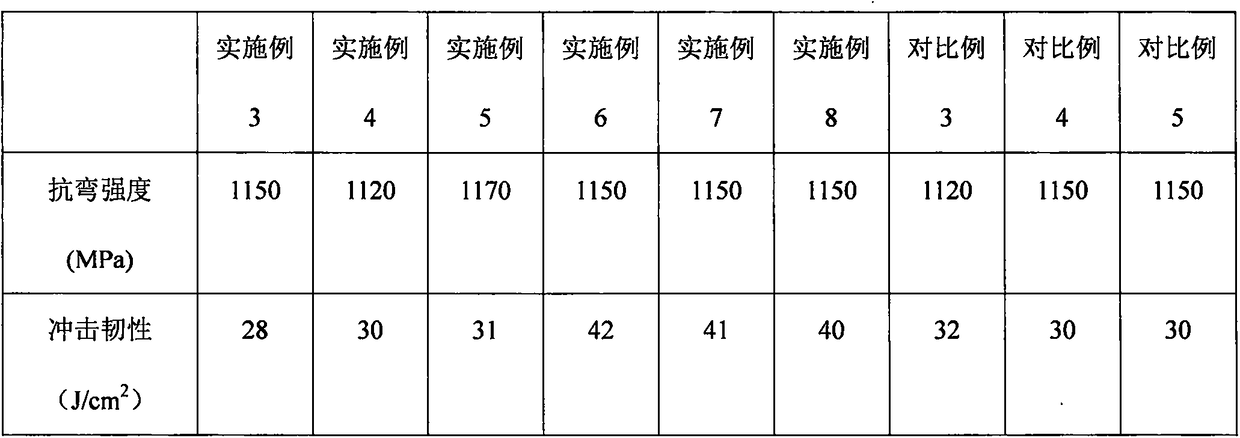

[0029] In this embodiment, 35% of the diamonds used have a particle size of 35 / 40, 40% of 40 / 45, and 25% of 45 / 50. Take 2.5kg of copper powder, 5.75kg of iron, 0.5kg of nickel, 0.7kg of cobalt, 0.4kg of tin, and 0.15kg of ferrophosphorus, put them into the mixing tank and mix for 30 minutes, add 0.06kg of liquid paraffin and 0.23kg of diamond, continue After mixing the materials for 4 hours, pour the powder into the mold for cold pressing and sintering. The hot pressing sintering temperature is 750°C and the pressure is 350kg / cm 2 , holding time is 180 seconds. Then use the grinding wheel and abrasive belt to grind the cutter head, put the cutter head and the substrate together on the corresponding substrate position according to the drawing requirements, adjust the light spot of the laser welding machine to the appropriate position between the cutter head and the substrate, and start the laser welding machine to weld, so that The cutter head and the substrate are welded toge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com