Chromium manganese silicon vanadium abrasion-resistant cast iron

An anti-wear cast iron and chromium-manganese-silicon technology, which is applied in the field of chromium-manganese-silicon-vanadium anti-wear cast iron, can solve the problems of increased production cost, high price, decreased wear resistance, etc., and achieves reduced production cost, low production cost and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A chromium-manganese-silicon-vanadium anti-wear cast iron. The chemical composition of the chromium-manganese-silicon-vanadium anti-wear cast iron is calculated by weight percentage: C3.4%, Cr 20%, Mn 2.5%, Si 0.8%, V 0.8%, P 0.06 %, S 0.06%, the rest is Fe and unavoidable impurities.

[0031] The eddy current flaw detection pinch roller of the steel plant manufactured by the chromium-manganese-silicon-vanadium wear-resistant cast iron has a service life three times that of the Cr12MoV steel.

Embodiment 2

[0033] A chromium-manganese-silicon-vanadium anti-wear cast iron. The chemical composition of the chromium-manganese-silicon-vanadium anti-wear cast iron is calculated by weight percentage: C 2.7%, Cr 16%, Mn 2.2%, Si 0.5%, V 0.5%, P 0.09 %, S 0.06%, the rest is Fe and unavoidable impurities.

[0034] Crusher hammers made of this chromium-manganese-silicon-vanadium-resistant cast iron have crushed 82,000 tons of cement clinker in a cement plant, while crusher hammers made of chromium-15-molybdenum-3 high-chromium cast iron have broken cement clinker Only 65,000 tons.

Embodiment 3

[0036] A chromium-manganese-silicon-vanadium anti-wear cast iron. The chemical composition of the chromium-manganese-silicon-vanadium anti-wear cast iron is calculated by weight percentage: C3.6%, Cr 22%, Mn 3.0%, Si 1.0%, V 1.0%, P 0.04 %, S 0.04%, the rest is Fe and unavoidable impurities.

[0037] The slurry pump sheath, impeller, guard plate and other flow parts produced by this chromium-manganese-silicon-vanadium anti-wear cast iron have a service life of 960 hours in a concentrator. The service life of the sheath, impeller and guard plate made of chromium 15 molybdenum 3 type high chromium cast iron is only 624 hours.

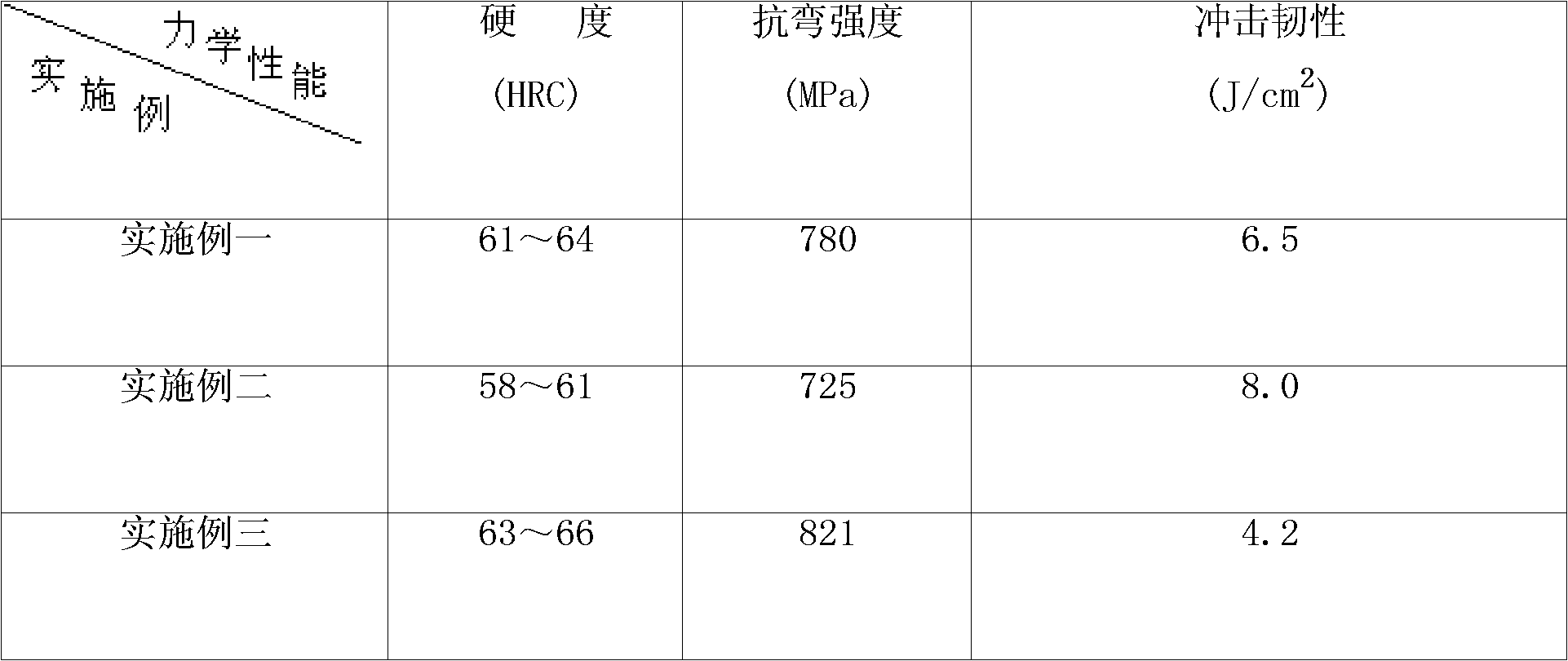

[0038] The mechanical properties of the chromium-manganese-silicon-vanadium wear-resistant cast irons described in the first to third examples above are tested respectively, and their mechanical properties are shown in attached table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com