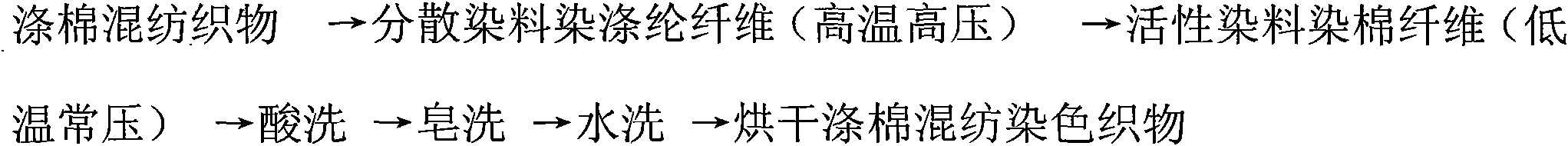

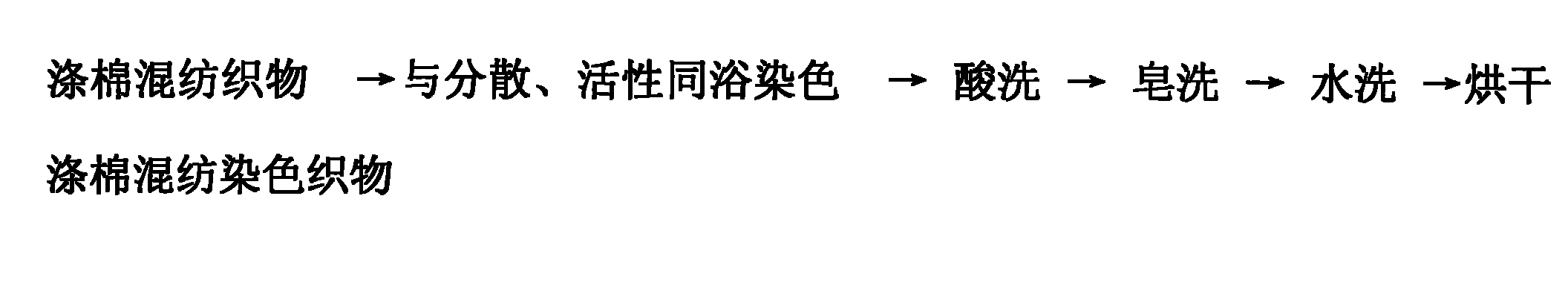

Cotton-polyester blended fabric and dispersive and reactive dye one-bath dyeing process

A polyester-cotton blended, reactive dye technology, applied in dyeing, textile and papermaking, etc., can solve the problems of high labor intensity, long production cycle, low production efficiency, etc., to improve the production efficiency of enterprises, large water consumption, save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Take 20×16 T65 and C35 108×58 polyester cotton olive green gauze as an example; the specific process steps are as follows:

[0020] 1. Small sample dithering: through laboratory sample dithering, select disperse dyes: disperse ruby H2GFL, disperse blue 2BLN, disperse yellow SE-RGFL; reactive dyes: reactive red B-3BF, reactive brilliant blue B-RV, reactive golden Color matching prescription of six dyes including B-4RFN;

[0021] 2. Prepare disperse and reactive dye dyeing solutions (dyeing solutions are prepared according to different hue requirements); the disperse dyes used are alkali-resistant disperse dyes; the reactive dyes used are high-temperature-resistant double-reactive B-type dyes;

[0022] 3. Put the polyester-cotton blended fabric into the high-temperature and high-pressure overflow dyeing machine;

[0023] 4. Slowly inject the mixture of disperse and reactive dyes into the high-temperature and high-pressure overflow dyeing machine, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com