Ultrasonic water tank for secondary water supply for residents on top floor of high-rise building and control method thereof

A technology of secondary water supply and ultrasonic wave, applied in the direction of using liquid cleaning method, water supply device, water saving, etc., can solve the problem of inconvenient use, etc., and achieve the effect of convenient time and cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

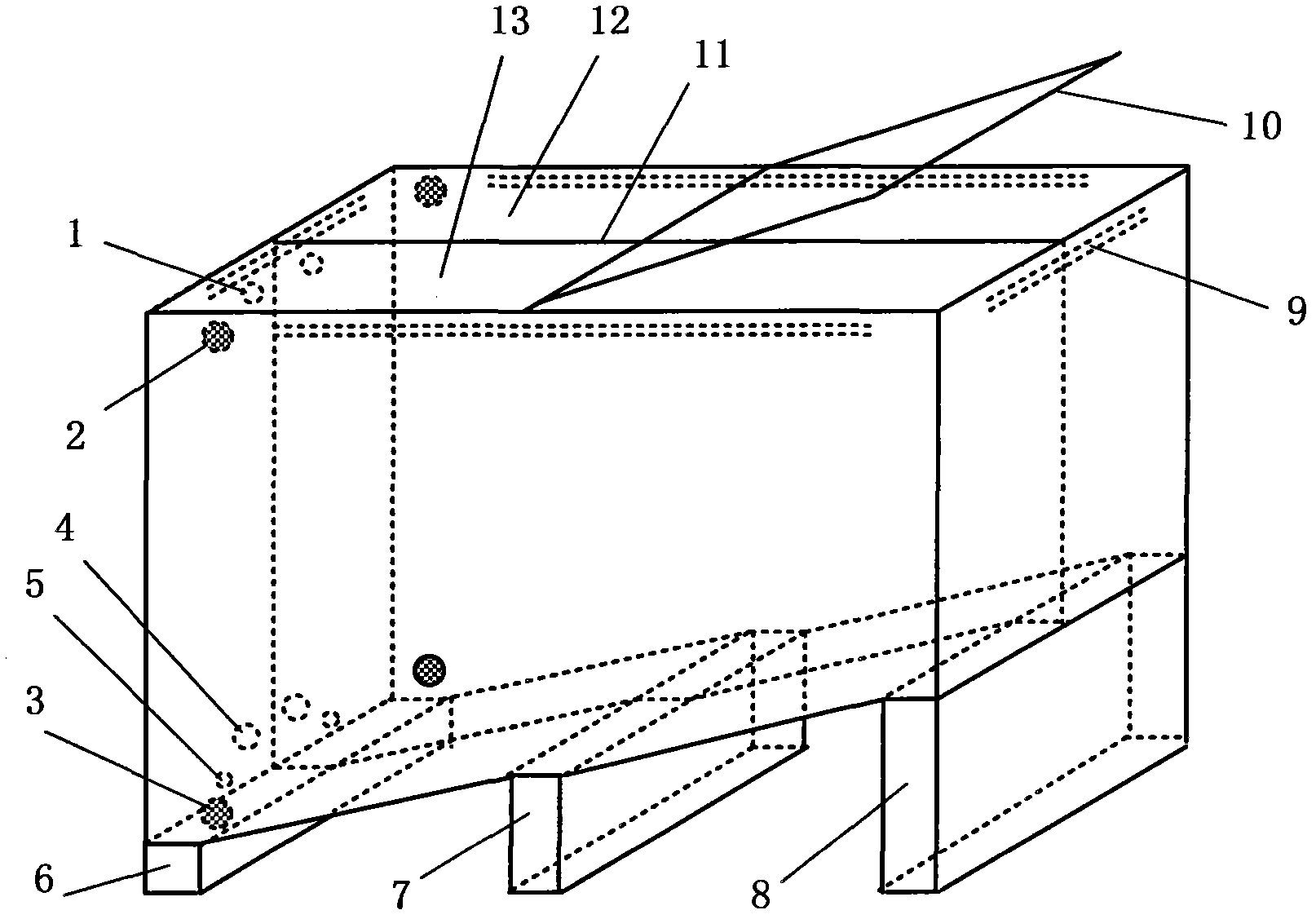

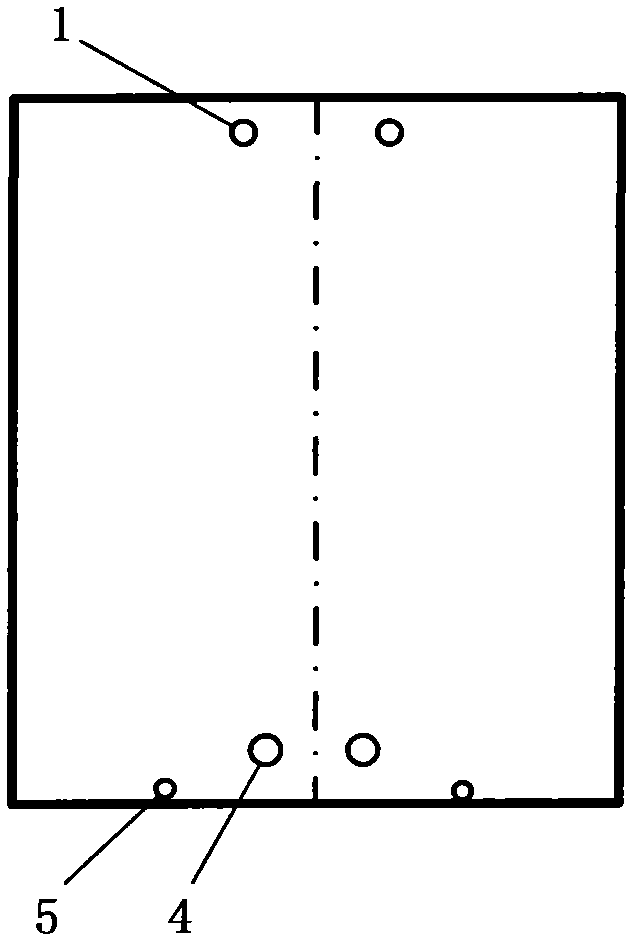

[0051] Such as figure 1 As shown, the ultrasonic water tank used for the secondary water supply of high-rise roof residents includes a box body, an ultrasonic system and a control system. The ultrasonic system is connected with the bottom plate 14 of the box, and the side plates around the box are provided with a water inlet 1, a cleaning water inlet 9, a water supply port 4 and a water discharge port 5; the water inlet 1 is externally connected to the water inlet pipe through the water inlet valve , the cleaning water inlet tank 9 is externally connected to the cleaning water inlet pipe through the cleaning valve, the water supply port 4 is externally connected to the water supply pipe through the water supply valve, and the drainage port 5 is provided with a drainage valve; There are water full sensor 2 and water empty sensor 3, and the control system is respectively connected with water full sensor 2, water empty sensor 3, water inlet valve, water supply valve, drain valve ...

Embodiment 2

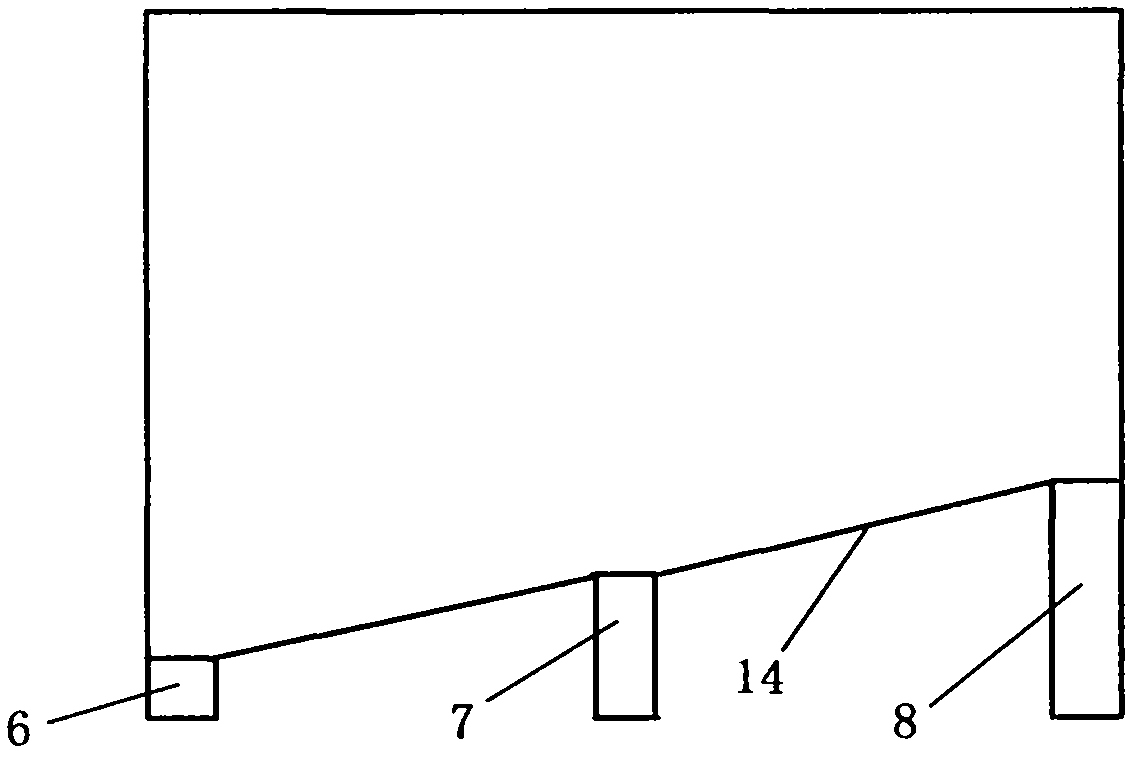

[0081] This embodiment has the same structure as Embodiment 1 except for the following features: the water inlet 1 and the water full sensor 2 are 40mm lower than the highest point on the top of the surrounding side plates, so that the effect of this is that water will not overflow due to water fullness It leads to waste of water resources; the water supply port 4 and the water-air sensor 3 are higher than the lowest point of the lower end of the surrounding side plates by 40mm. The drain outlet 5 is tangent to the lowest point of the bottom of the casing, which is beneficial to the smooth discharge of sedimentation debris and the like, and plays the best cleaning effect.

[0082] The included angle between the bottom plate 14 and the horizontal plane is 15 degrees; the number of the support columns is 5.

Embodiment 3

[0084] This embodiment has the same structure as Embodiment 1 except for the following features: the water inlet 1 and the water full sensor 2 are 30mm lower than the highest point on the top of the surrounding side plates, so that the effect of this is that water will not overflow due to full water It leads to waste of water resources; the water supply port 4 and the water-air sensor 3 are 30mm higher than the lowest point of the lower end of the surrounding side plates. The drain outlet 5 is tangent to the lowest point of the bottom of the casing, which is beneficial to the smooth discharge of sedimentation debris and the like, and plays the best cleaning effect.

[0085] The included angle between the bottom plate and the horizontal plane is 13 degrees; the number of the support columns is 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com