Composite resin material with improved performance and application of composite resin material in automobile decoration material

A composite resin and modified resin technology, applied in the field of resin grafting modification and compounding, can solve the problems of difficulty in meeting the requirements of the blending system, large differences in the properties of the modified resin, inconvenient construction of the coupling agent, etc. The effects of pollution, improvement of interfacial adhesion, and simple and feasible preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

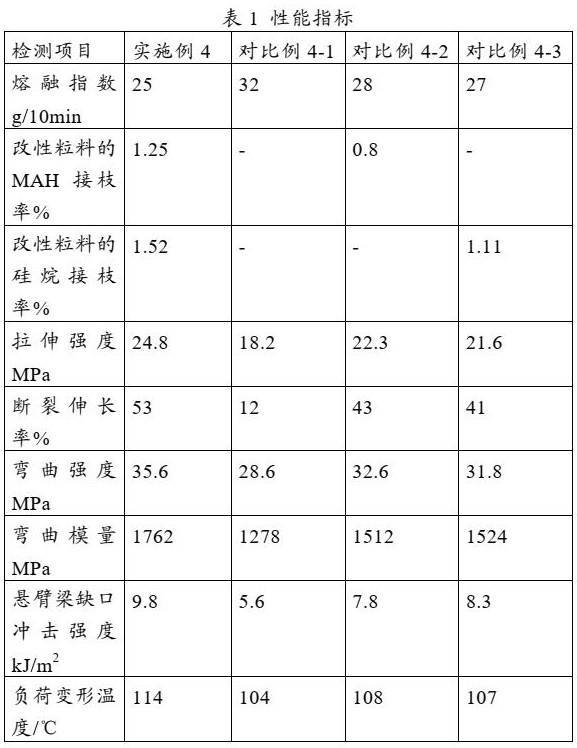

Examples

Embodiment 1

[0049]Preparation 1 of embodiment 1-modified resin

[0050] Mix 1.0 part of MAH, 0.1 part of antioxidant (compounded by antioxidants AO1010 and AO168 at a mass ratio of 1:1) and 100 parts of POE particles or powder through a temperature-controlled high-mixer for 2 minutes at a temperature of 25 °C, with a rotation speed of 500 rpm; then reduce the rotation speed to 50 rpm, and add 0.1 part of dicumyl peroxide crosslinking agent and 1 part of silane coupling agent A171 evenly by spraying. After the addition is complete, mix at a high speed of 700r / min at a temperature of 25°C for 10 minutes to obtain a premix; finally, the premix is granulated through a twin-screw extruder with a length-to-diameter ratio of L / D of 44:1 to obtain modification Resin pellets.

[0051] The temperature of each zone of the extruder is: 80°C in the feeding zone, 140°C in the pre-melting zone, 200°C in the melting zone, 190°C in the metering zone, 200°C in the head, and 300 rpm.

Embodiment 2

[0052] Preparation 2 of embodiment 2-modified resin

[0053] Mix 1.0 part of MAH, 0.1 part of antioxidant (compounded by antioxidants AO1010 and AO168 at a mass ratio of 1:1) and 100 parts of EVA particles or powder through a temperature-controlled high-mixer for 2 minutes at a temperature of 25 °C, with a rotation speed of 500 rpm; then reduce the rotation speed to 50 rpm, and add 0.1 part of dicumyl peroxide crosslinking agent and 1 part of silane coupling agent A171 evenly by spraying. After the addition is complete, mix at a high speed of 700r / min at a temperature of 25°C for 10 minutes to obtain a premix; finally, the premix is granulated through a twin-screw extruder with a length-to-diameter ratio of L / D of 44:1 to obtain modification Resin pellets.

[0054] The temperature of each zone of the extruder is: 80°C in the feeding zone, 140°C in the pre-melting zone, 200°C in the melting zone, 190°C in the metering zone, 200°C in the head, and 300 rpm.

Embodiment 3

[0055] Preparation 3 of embodiment 3-modified resin

[0056] Mix 3.0 parts of MAH, 0.1 part of antioxidant (compounded by antioxidants AO1010 and AO168 at a mass ratio of 1:1) and 100 parts of POE particles or powder through a temperature-controlled high-mixer for 2 minutes at a temperature of 25 °C, with a rotation speed of 500 rpm; then reduce the rotation speed to 50 rpm, and add 0.1 parts of dicumyl peroxide crosslinking agent and 3 parts of silane coupling agent A171 evenly by spraying. After the addition is complete, mix at a high speed of 700r / min at a temperature of 25°C for 5 minutes to obtain a premix; finally, the premix is granulated through a twin-screw extruder with a length-to-diameter ratio of L / D of 44:1 to obtain modification Resin pellets.

[0057] The temperature of each zone of the extruder is: 80°C in the feeding zone, 140°C in the pre-melting zone, 200°C in the melting zone, 190°C in the metering zone, 200°C in the head, and 300 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com