Cavern protection method

A technology for karst caves and branch caves, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of high rockfall impact strength, tunnel construction and operation hazards, tunnel cracking, etc., to achieve simple construction and ensure construction and operation safety. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

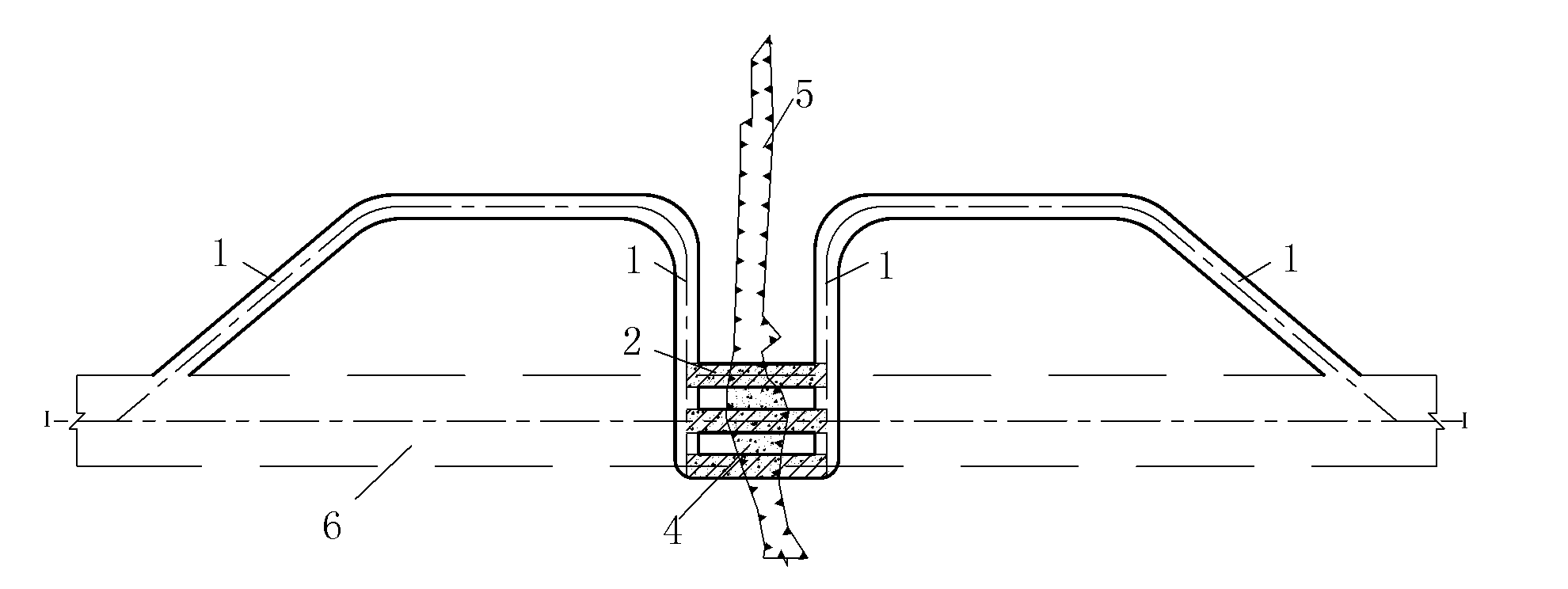

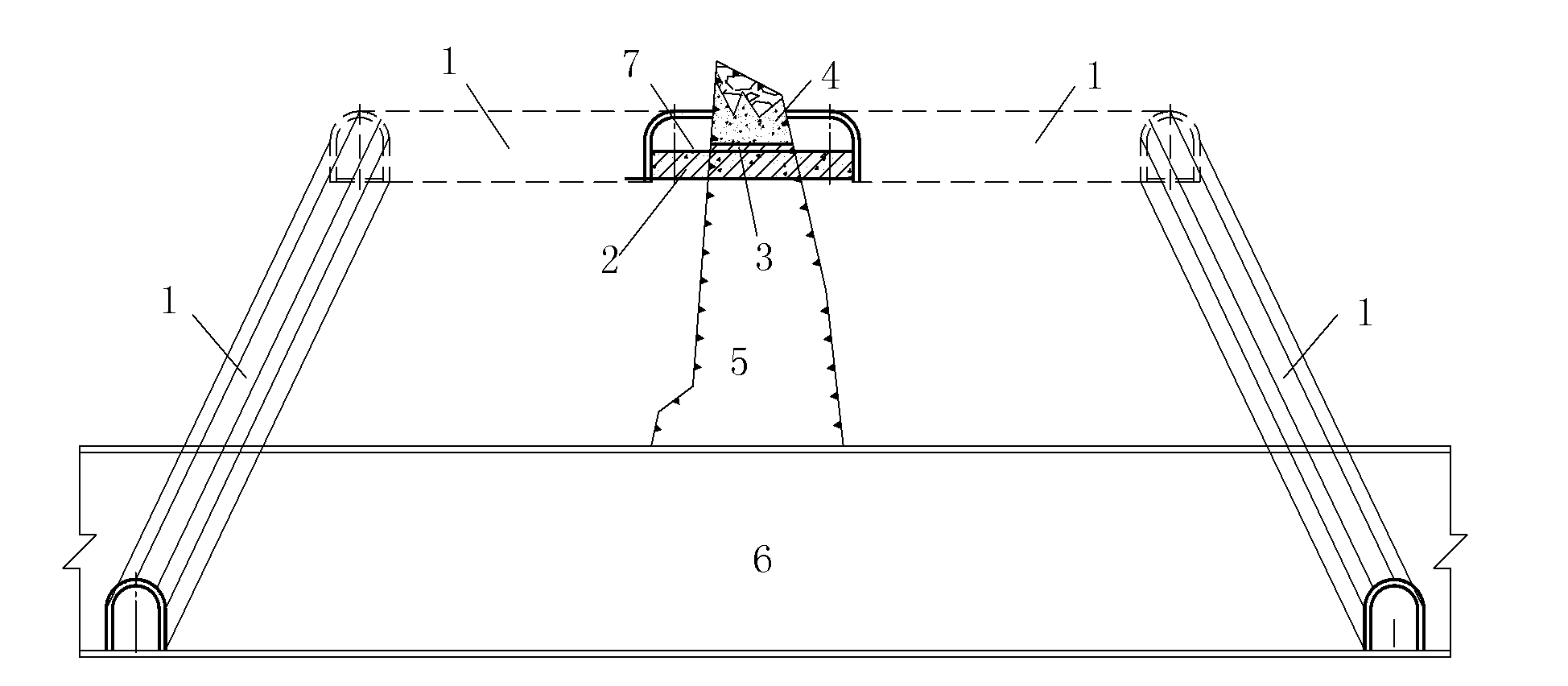

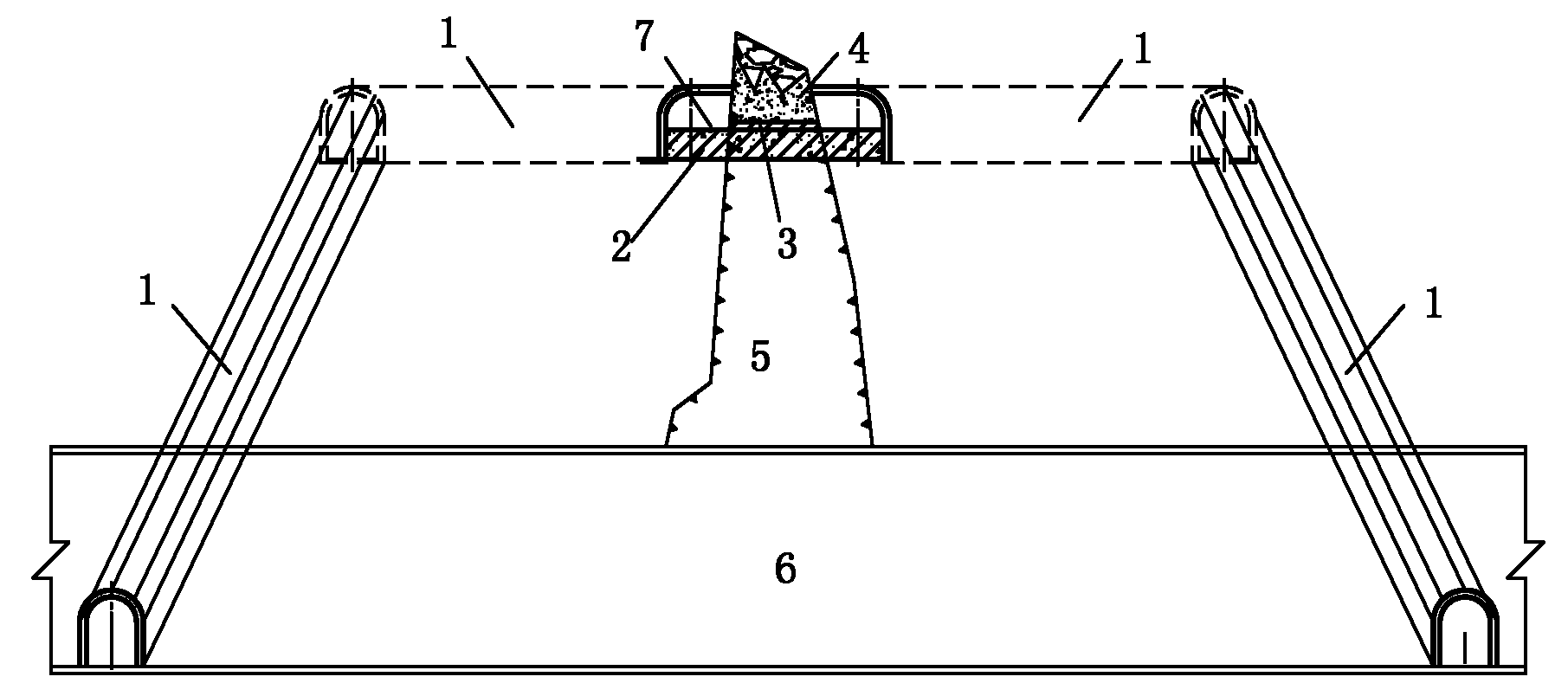

[0019] Example: such as figure 1 , 2 As shown, this example involves the protection method for preventing rockfall in tunnels passing through high, steep and narrow karst caves. The specific implementation steps are:

[0020] a. Set up a roundabout branch hole 1 at the side wall of the tunnel 6 and climb to the top of the empty cave 5, and open a vertical branch hole between the roundabout branch holes on both sides of the above-mentioned karst cave directly above the tunnel, and the roundabout branch holes on both sides of the karst cave 1. The elevation of the bottom of the pit is the same. According to the required protection width and the lateral spacing of the longitudinal beams 2, multiple longitudinal branch holes 11 can be opened;

[0021] b. Set the longitudinal beam 2 at the top of the karst cave 5 by using the longitudinal branch hole 11, and the support of the longitudinal beam 2 is located in the longitudinal branch hole 11;

[0022] c. Lay a concrete slab 3 hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com