Circular arc-shaped furniture edge and corner component and manufacture process thereof

A manufacturing process and arc-shaped technology, which are applied in the field of arc-shaped furniture corner parts and their manufacturing processes, furniture parts and their manufacturing processes, and can solve the problems that affect the health of users, are difficult to meet mass production, and have poor surface wear resistance. It can achieve the effect of easy batch production, cost saving and strong environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

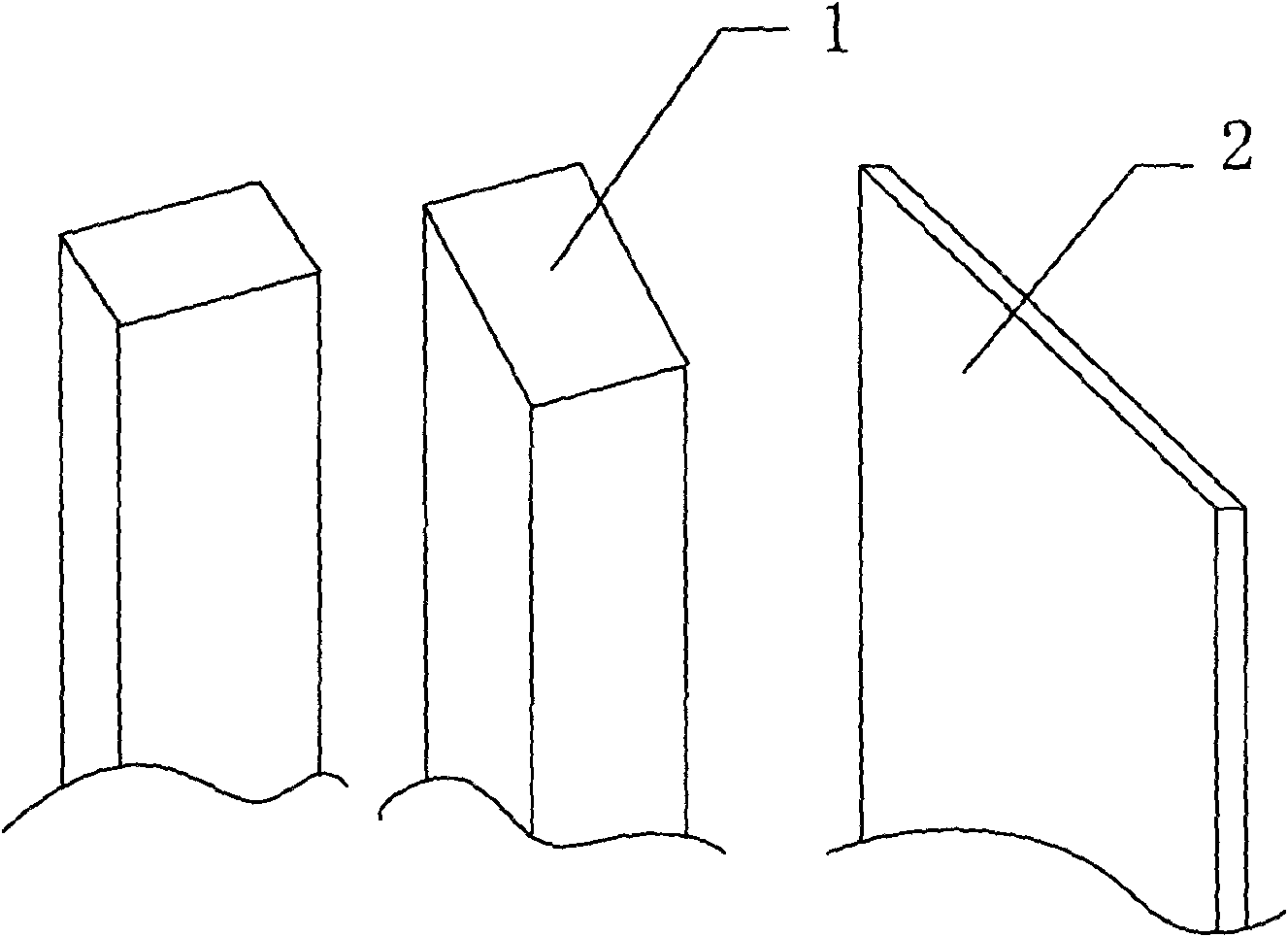

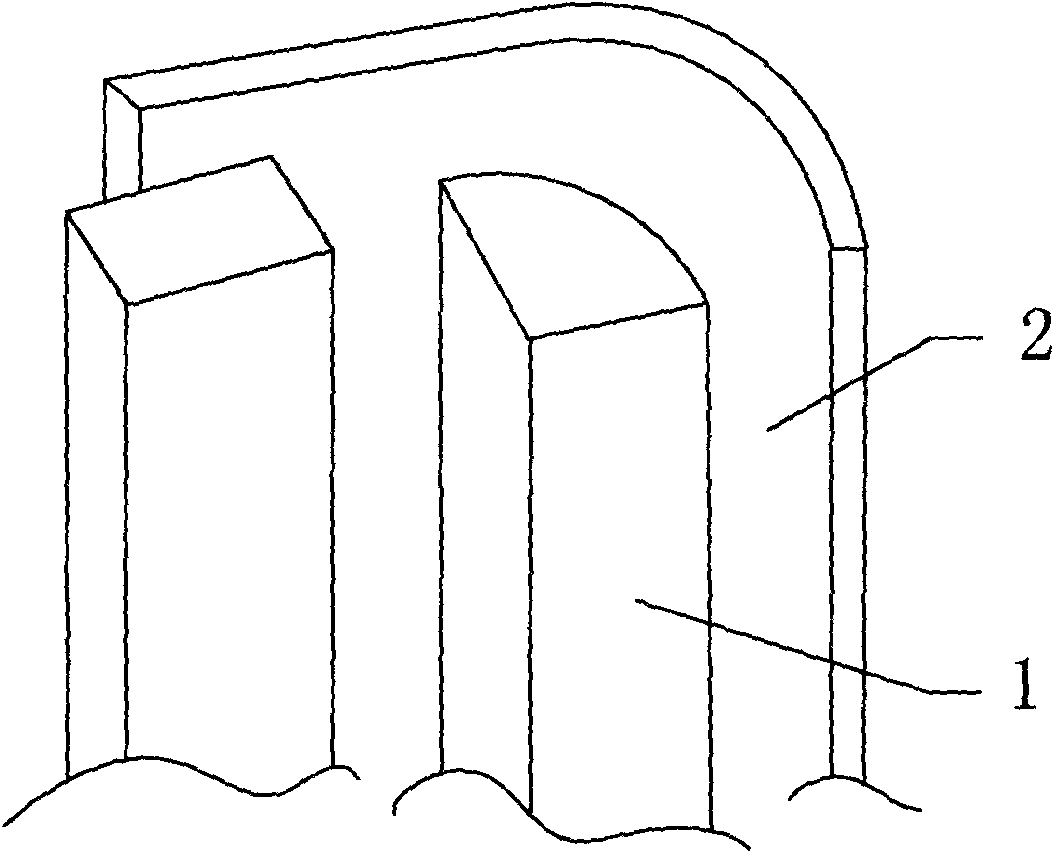

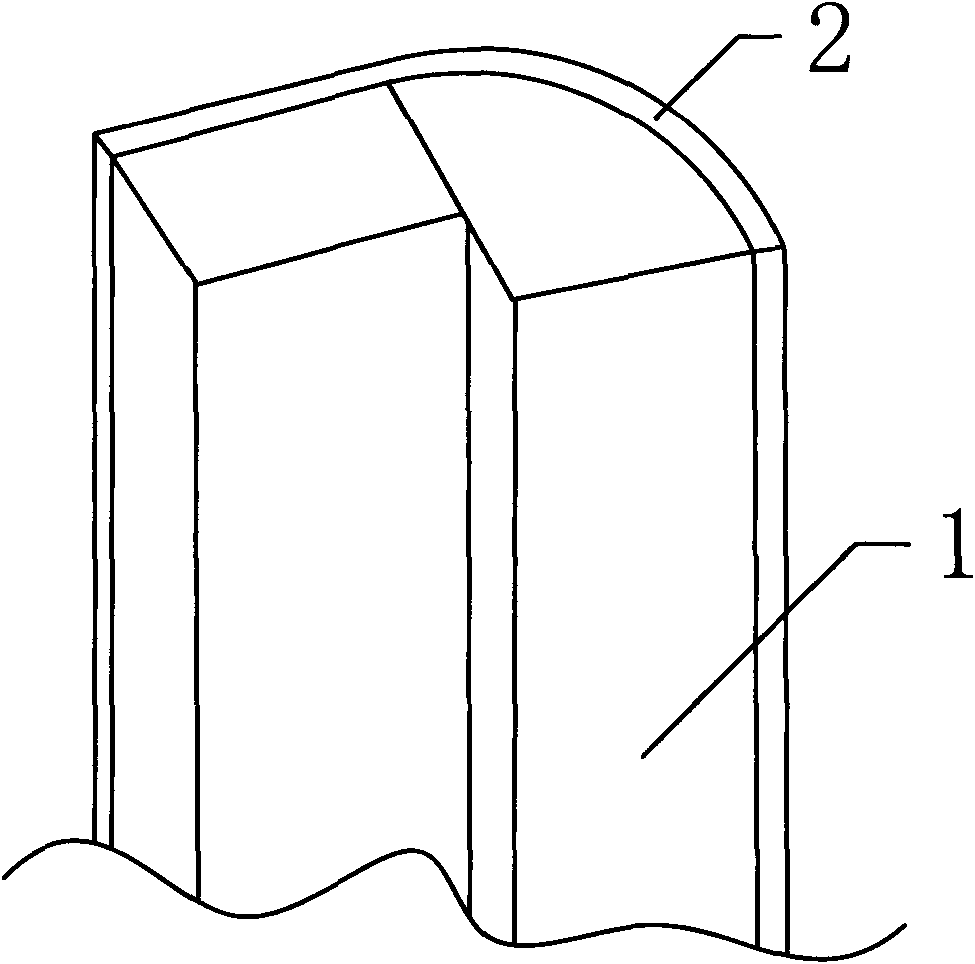

[0028] Such as Figure 1~3 The arc-shaped furniture corner parts shown are different in that: the part includes an inner arc lath 1, which is covered with a non-painted arc decorative plate 2, and the inner arc lath 1 is composed of wood-based panel residues, and the material of arc decorative panel 2 is melamine physical and chemical board, or acrylic board, or fireproof board, or stainless steel plate. Looking further, in order to ensure that the degree of stress of the arc-shaped furniture corner parts meets the use requirements in practical applications, there are at least two inner arc-shaped slats 1, and the two are arranged and merged with each other and are supported by the arc-shaped decorative plate 2. Partial coverage. Considering that the arc decorative panel 2 can also bear a certain external stress, its thickness is 1-4 mm.

[0029] In view of the manufacturing process of the arc-shaped furniture corner parts, it includes the following steps: first, select the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com