Electronic expansion valve structure

A technology of electronic expansion valve and valve body, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of unoptimized system, valve needle noise, long working stroke of valve needle, etc., achieve refrigeration system optimization and increase energy consumption than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

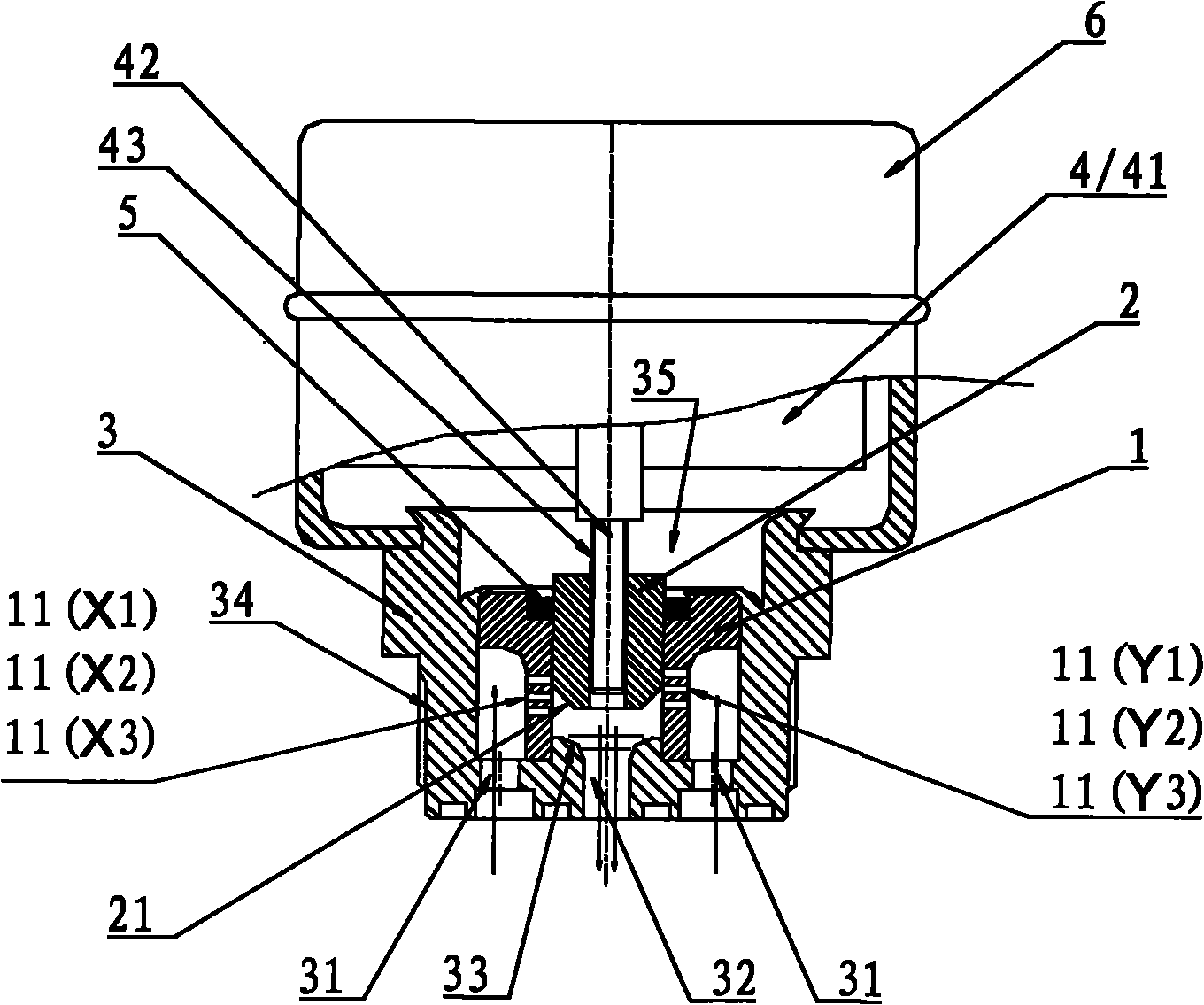

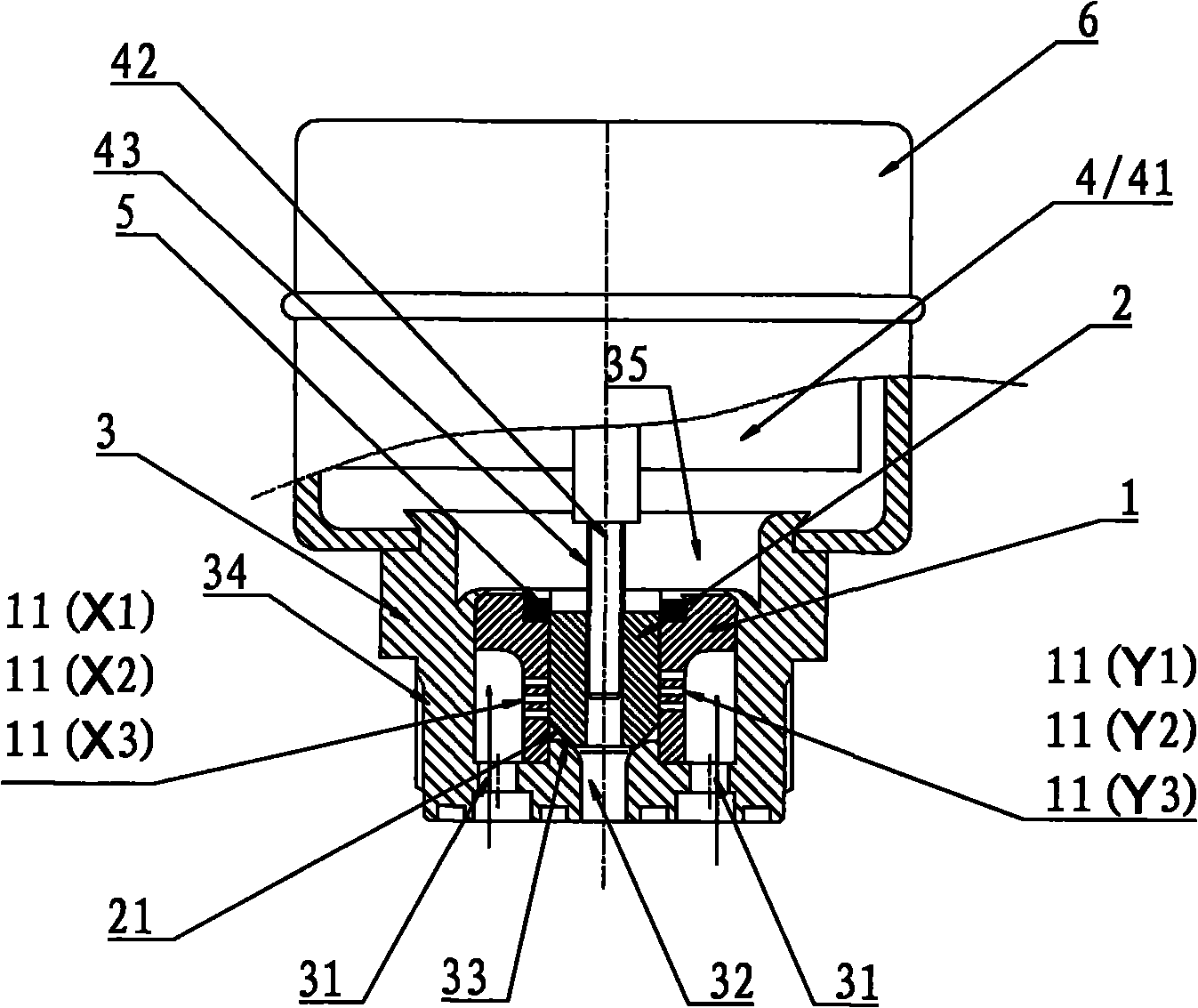

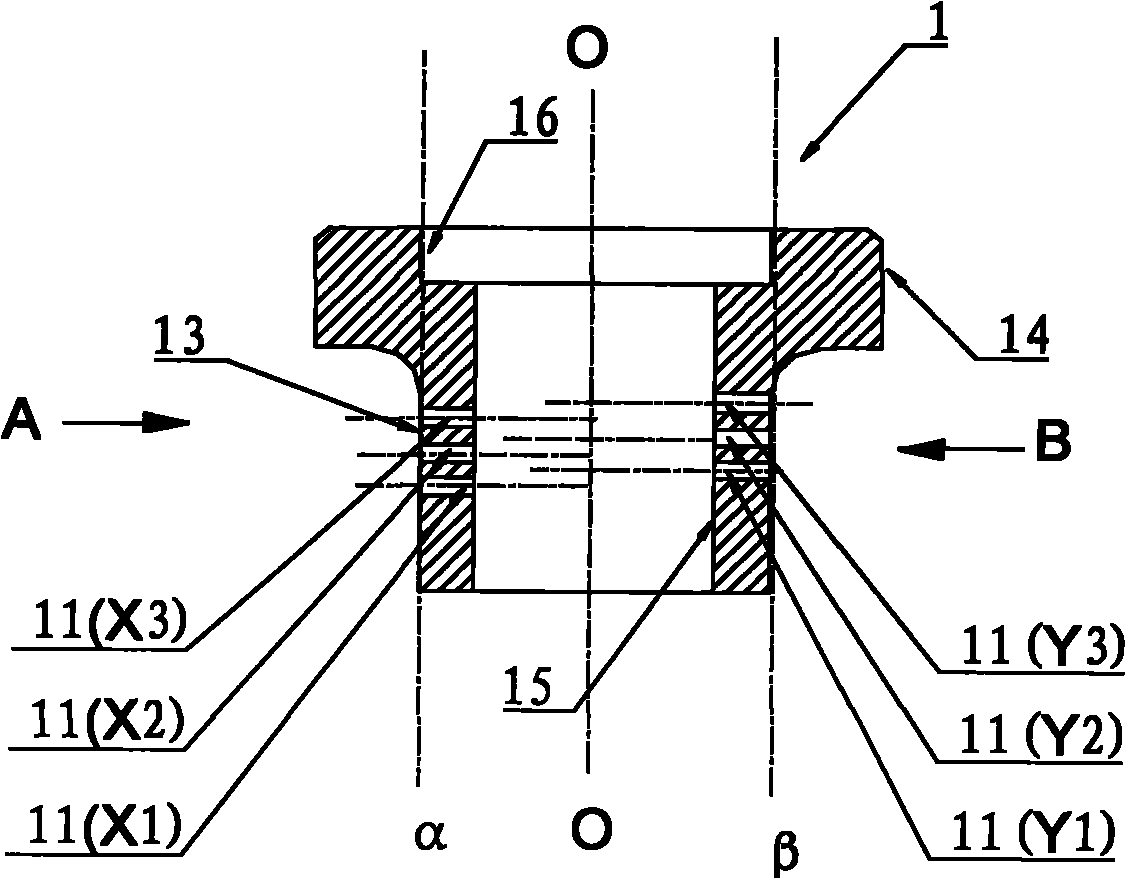

[0056] Figure 1A It is a schematic structural diagram of one of the specific embodiments provided by the present invention under the throttling working state; Figure 1B It is a schematic structural diagram of the specific embodiment in a closed state; image 3 It is a front view and a side view of the anti-rotation gasket structure in the above embodiment; Figure 4It is the front view and top view of the spool structure.

[0057] Such as Figure 1A and Figure 1B shown. The structure of the electronic expansion valve includes a cover body 6 riveted and fixed to the valve body 3 and a drive motor 41 (a stepper motor in this embodiment) fixed in the cover body 6. The front end of the motor 41 is connected with a transmission shaft 42 to drive The motor 41 and the drive shaft 42 together form the drive device 4 . The detection control module of the refrigeration system (such as air conditioner) converts the detected parameters such as the pressure / temperature change of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com