Error prevention system and error prevention method for clutch assembly assembly line

A technology of assembly assembly and error-proofing system, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as easy mixing of materials, product performance requirements and output requirements that cannot meet the standards, and achieve strong error-proofing capabilities and meet Product performance requirements, the effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

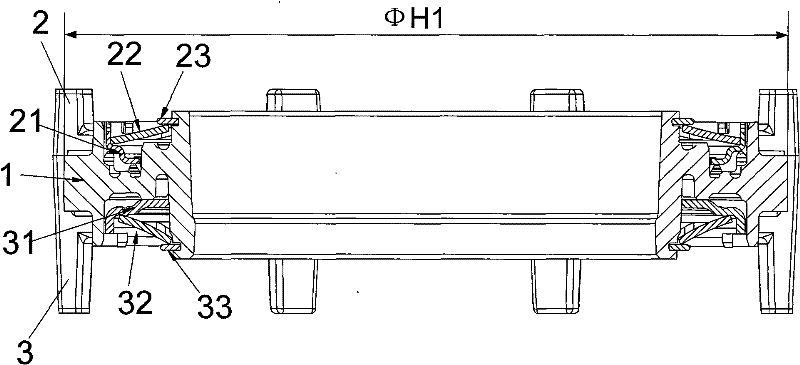

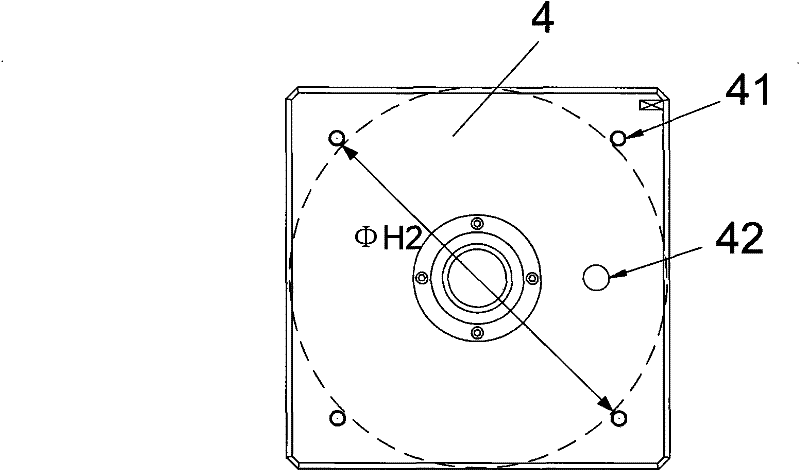

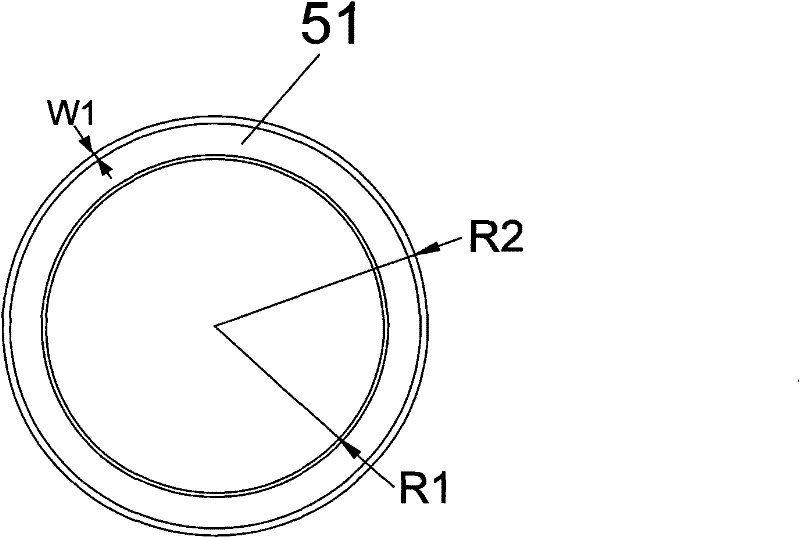

[0041] see Figure 2 to Figure 11 , the present invention is used for the error proofing system of the clutch assembly assembly line, the error proofing system is installed on the clutch assembly assembly line, and the clutch assembly assembly line includes a housing tray 4 for placing the clutch housing 1, A piston material rack with a base 53 for placing the piston 51, a piston manipulator claw 56 with three inner supporting mechanical fingers 57 for grabbing the piston 51, a spring with a base 62 for placing the spring 61 The material rack is used to grab the spring 61, is provided with four spring manipulator claws 65 evenly distributed on the same semicircle of the vacuum chuck 66, is used to place the card rib 71, has the card rib material rack with the base 72 and uses On the bottom surface of the grasping rib 71, there are four rib manipulator claws 74 evenly distributed on the magnetic chuck 75 on the same circumference. The outer diameter of the clutch housing 1 is Φ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com