Yarn splicing device and textile machine equipped with the same

A joint device and equipment technology, which is applied in the field of fiber machinery, can solve the problems of difficult fluid flow setting, setting error, and difficulty in immediately changing the flow adjustment mechanism, etc., and achieves the effect of high reproducibility and suppression of fluid turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

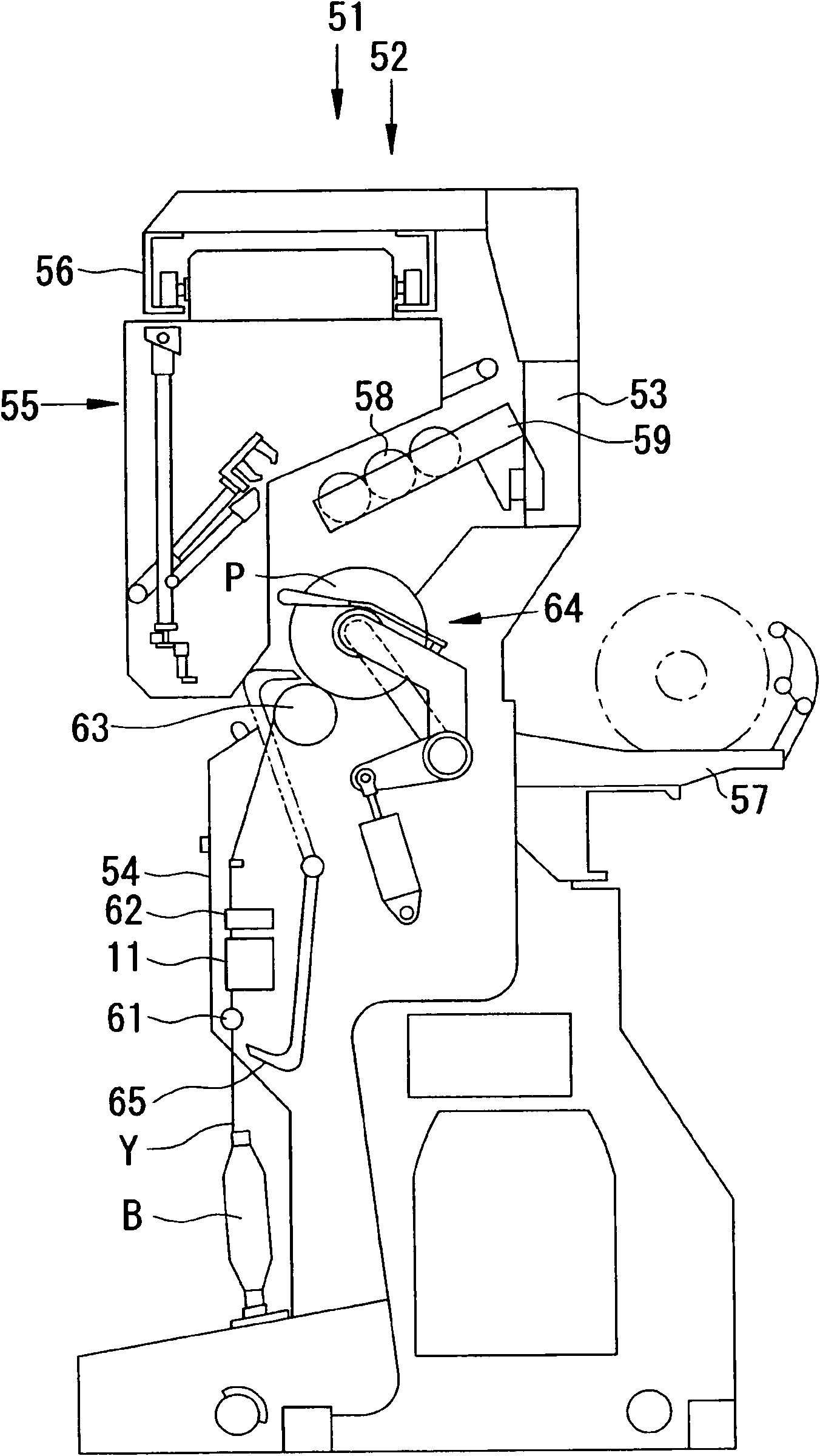

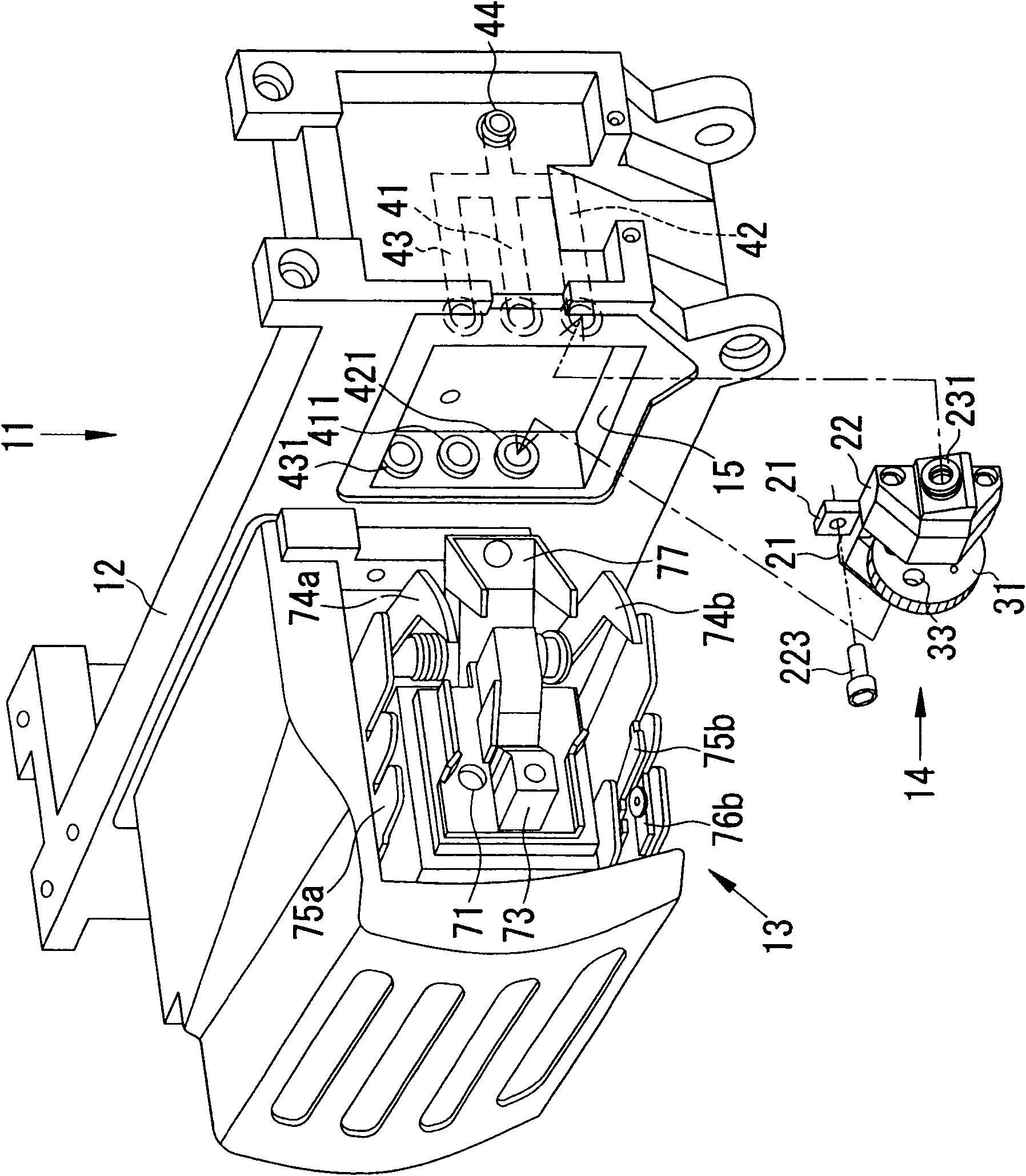

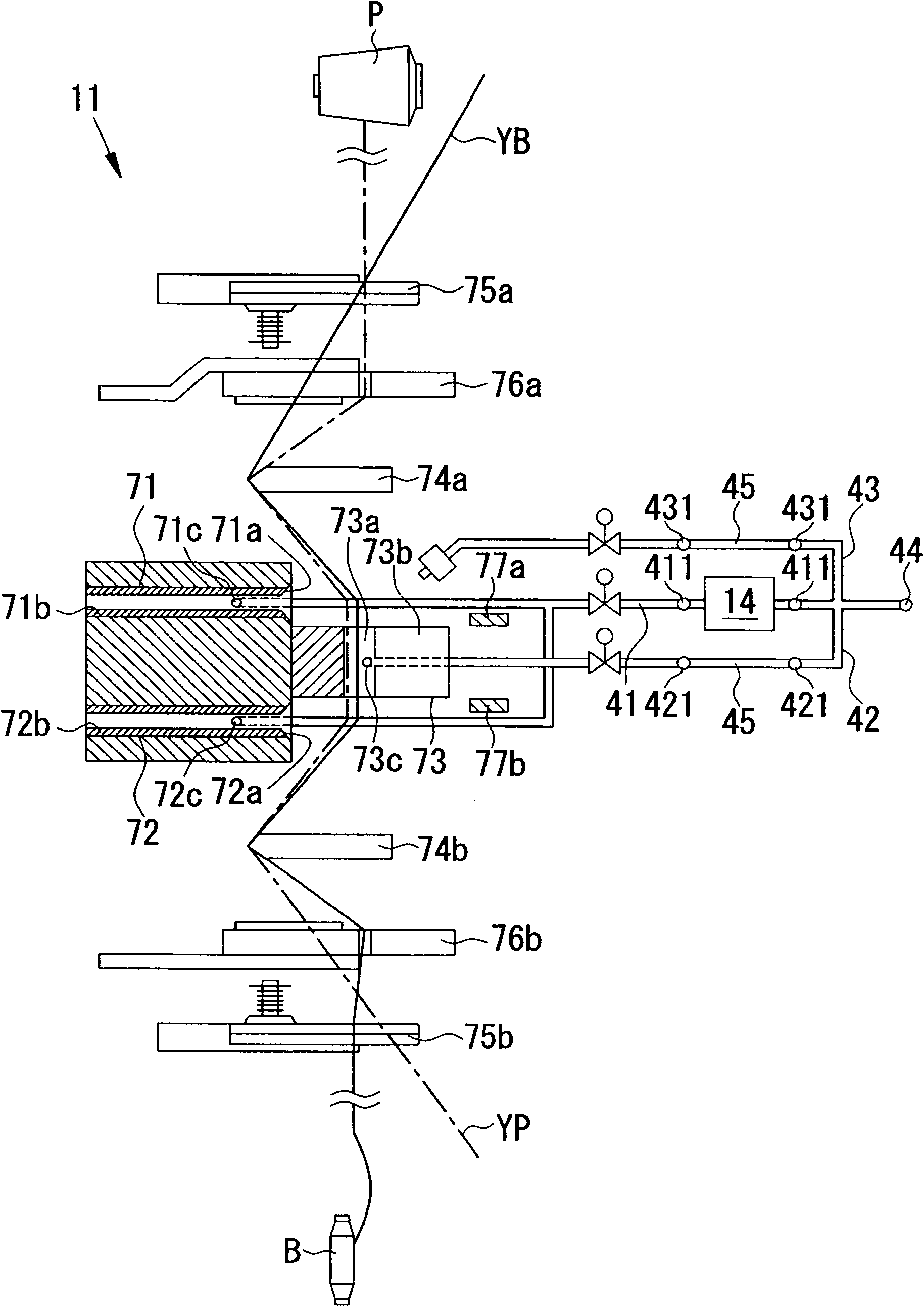

[0034] figure 1 A sectional view showing a winder 51 as a textile machine using the yarn joining device 11 according to the first embodiment of the present invention. The winder 51 has a plurality of yarn winders 52 arranged side by side in one direction, and the yarn winders 52 in the winder 51 rewind the yarn Y of the yarn supplying bobbin B to form a package P. In addition, although the case where the yarn joining device 11 of the present invention is used in the winder 51 will be described below, the yarn joining device 11 of the present invention can also be used to convert a fiber bundle into a spun yarn and wind it up to form a package. P spinning machinery.

[0035] Such as figure 1 As shown, the main frame 53 is arranged along the direction in which the yarn winding machines 52 are arranged side by side. The main frame 53 supports a unit frame 54 for supporting devices constituting the yarn winding machine 52 and a rail 56 for running the doffing device 55 in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com