Method for dehydration and recycling of continuous dyeing sludge

A printing and dyeing sludge recycling technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of printing and dyeing sludge environmental pollution, to eliminate pollution, Save floor space and achieve continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

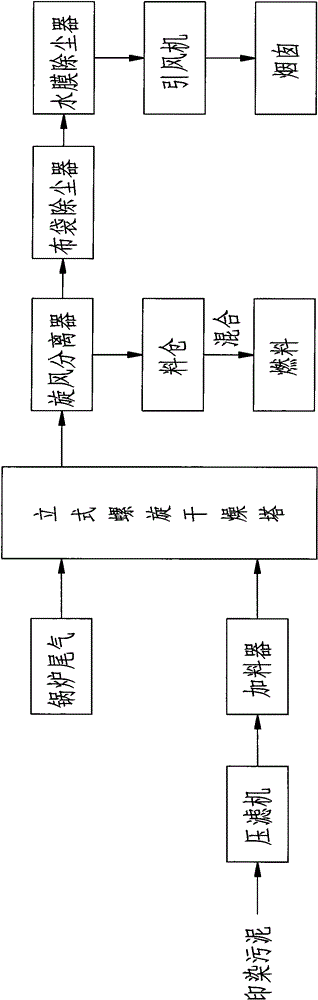

[0014] like figure 1 As shown, the continuous printing and dyeing sludge drying treatment and resource utilization method includes the following process steps: (1), dehydration: the printing and dyeing sludge with a moisture content of about 99% is introduced into the filter press through a sludge pump, and then Adding flocculant for dehydration, the flocculant is polyacrylamide with a concentration of 0.4‰, its addition amount is 6‰ of the dry sludge mass, and the moisture content of the printing and dyeing sludge after dehydration is 85%;

[0015] (2) Drying: The dehydrated printing and dyeing sludge is sent to the screw feeder through the conveyor belt, and then sent to the vertical screw drying tower by the rotary feeder for drying. The air duct tangentially enters the vertical spiral drying tower to ensure that the hot air volume is 18000m 3 / h, maintain the dynamic balance of the air intake, and the moisture content of the printing and dyeing sludge after drying is 30%;...

Embodiment 2

[0019] like figure 1 As shown, the continuous printing and dyeing sludge drying treatment and resource utilization method includes the following process steps: (1), dehydration: the printing and dyeing sludge with a moisture content of about 92% is introduced into the filter press through a sludge pump, and then Adding flocculant for dehydration, the flocculant is polyacrylamide with a concentration of 0.6‰, the amount added is 4‰ of the dry sludge mass, and the moisture content of the printing and dyeing sludge after dehydration is 80%;

[0020] (2) Drying: The dehydrated printing and dyeing sludge is sent to the screw feeder through the conveyor belt, and then sent to the vertical screw drying tower by the rotary feeder for drying. The tangential air inlet of the air duct leads into the vertical spiral drying tower to ensure that the hot air volume is 22000m 3 / h, maintain the dynamic balance of the air intake, and the moisture content of the printing and dyeing sludge afte...

Embodiment 3

[0024] like figure 1 As shown, the continuous printing and dyeing sludge drying treatment and resource utilization method includes the following process steps: (1), dehydration: the printing and dyeing sludge with a water content of about 95% is introduced into the filter press through a sludge pump, and then Adding a flocculant for dehydration, the flocculant is polyacrylamide with a concentration of 0.5‰, the amount added is 5‰ of the dry sludge mass, and the moisture content of the printing and dyeing sludge after dehydration is 83%;

[0025] (2) Drying: The dehydrated printing and dyeing sludge is sent to the screw feeder through the conveyor belt, and then sent to the vertical screw drying tower by the rotary feeder for drying. The tangential air inlet of the air duct leads into the vertical spiral drying tower to ensure that the hot air volume is 20,000m 3 / h, maintain the dynamic balance of the air intake, and the moisture content of the printing and dyeing sludge afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com