Manual pilot combined operating valve for hydraulic support

A technology of hydraulic supports and pilot valves, which is applied in the direction of pillars/supports, servo motor components, fluid pressure actuators, etc., can solve problems affecting labor efficiency, fatigue, and labor-intensive operations of staff, so as to reduce manual operating force and improve The effect of speed of operation and simplification of maintenance links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

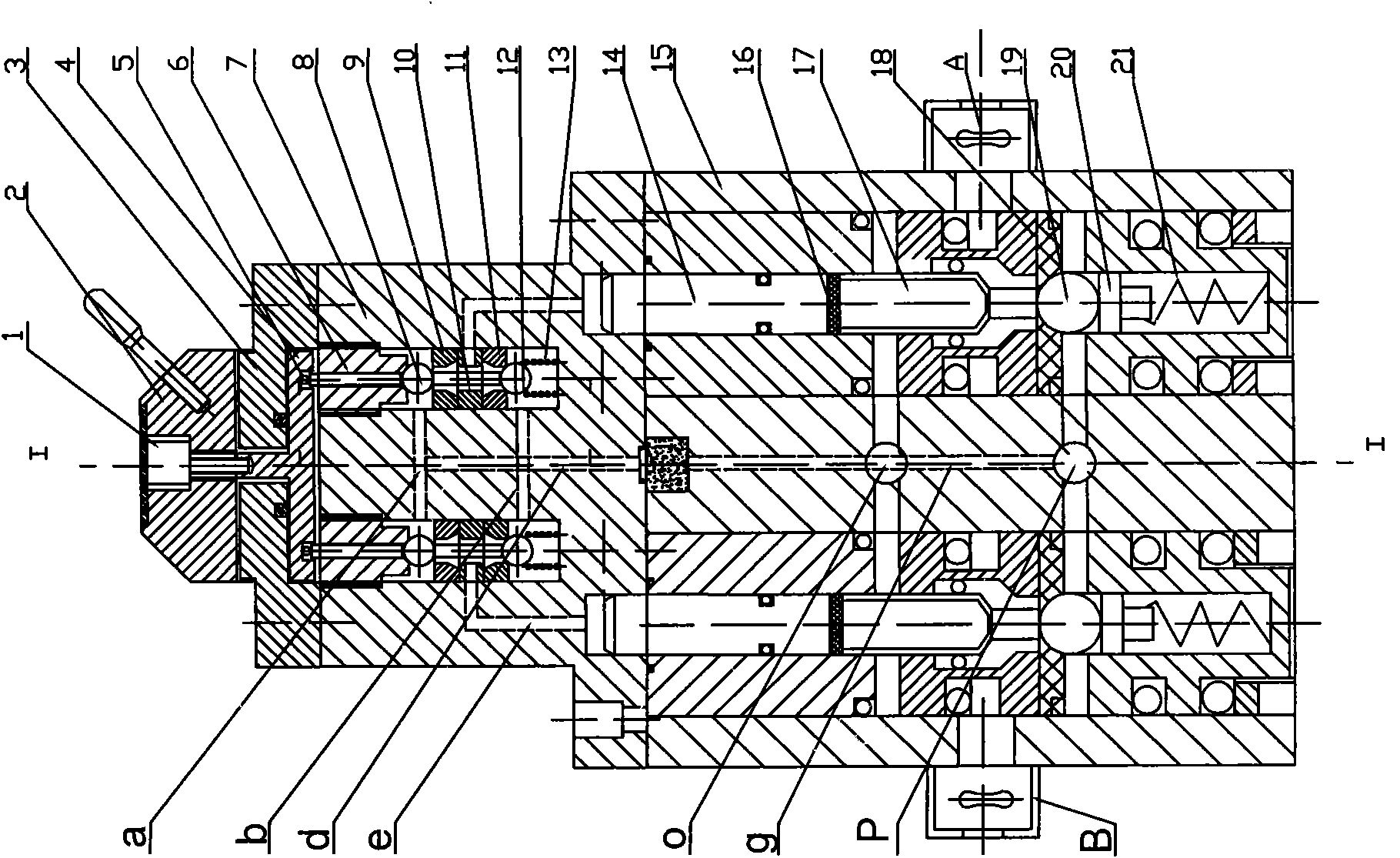

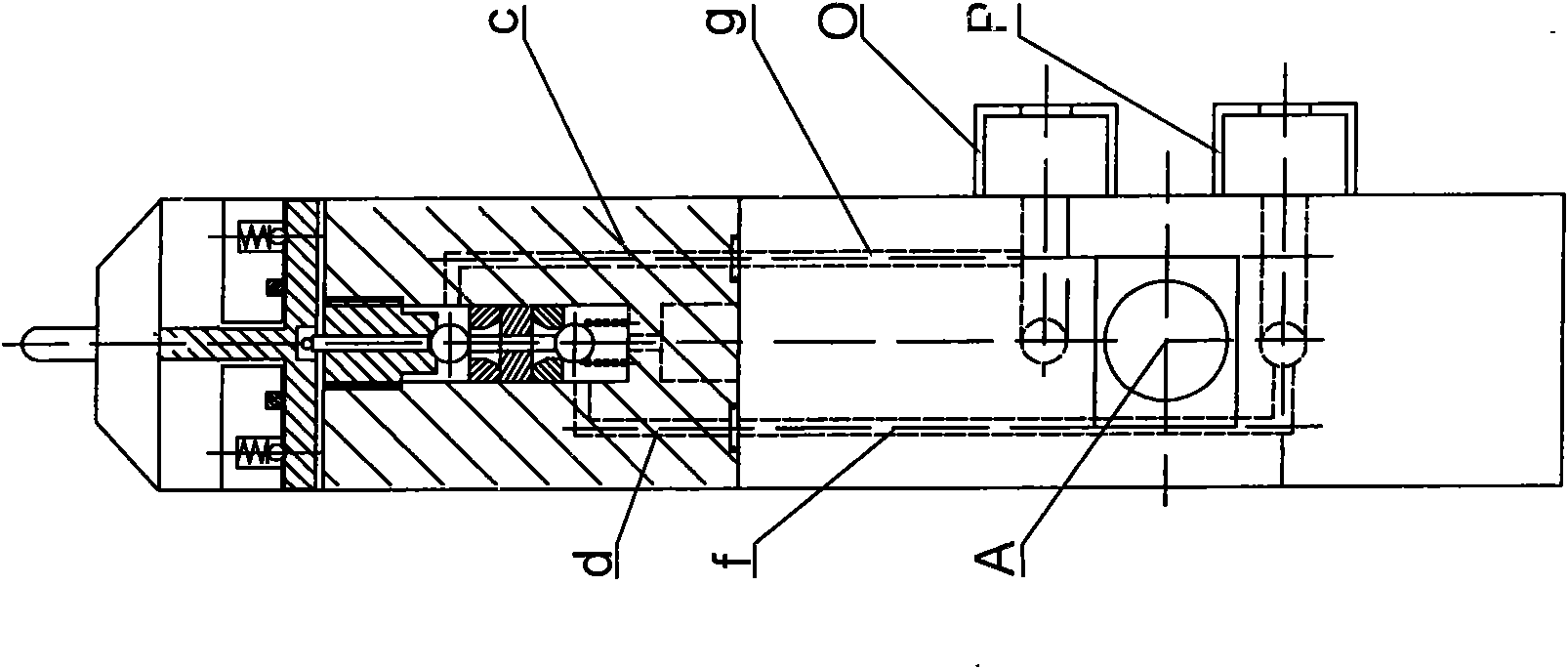

[0021] Such as figure 1 with figure 2 As shown, the present invention mainly comprises a handle control mechanism, a main control valve of a large flow rate and a pilot valve of a small flow rate.

[0022] The main control valve includes a housing 15, main oil ports A and B on the housing, and two valve chambers in the housing 15; the valve chamber is provided with a main valve spring 21 and a spring seat 20 sequentially from bottom to top. , Main valve ball core 19, main valve ball seat 18, main valve core 17, valve pad 16 and main valve core control rod 14. Two vertical oil passages are also processed in the housing 15 of the main control valve, one of which is a low-pressure oil passage g, and the low-pressure oil passage g connects the low-pressure oil port 0 of the main control valve with the low-pressure oil passage of the pilot valve. c is connected, and the other vertical oil passage is high-pressure oil passage f, which connects the high-pressure oil port P of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com