Mass balancing mechanism

A technology of mass balance and transmission mechanism, which is applied in the direction of engine components, mechanical equipment, vibration suppression adjustment, etc., can solve the problems of high friction power, loss, etc., and achieve the effect of sufficient lubrication and/or cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

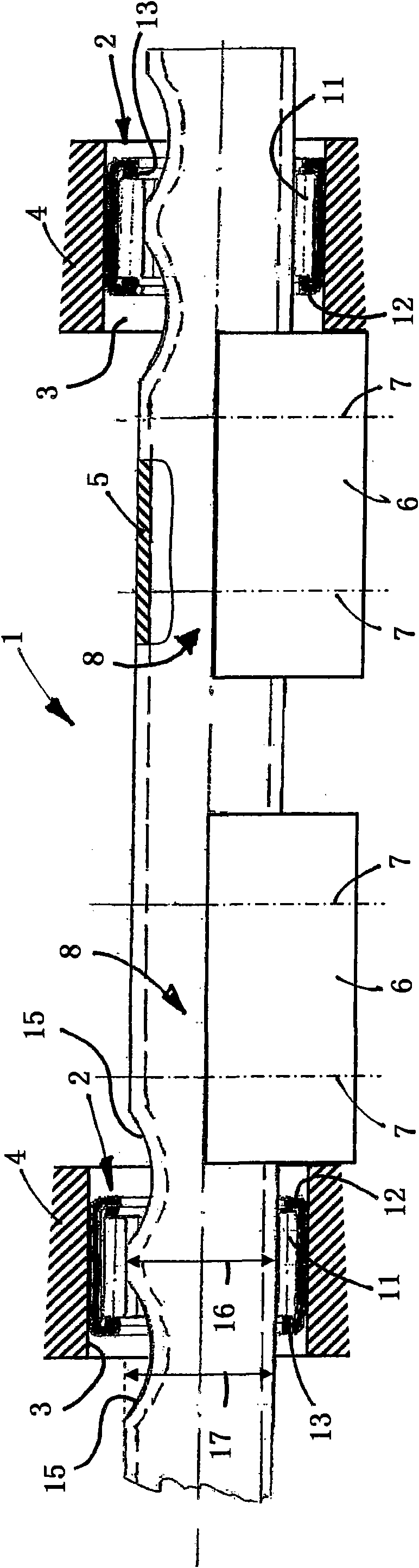

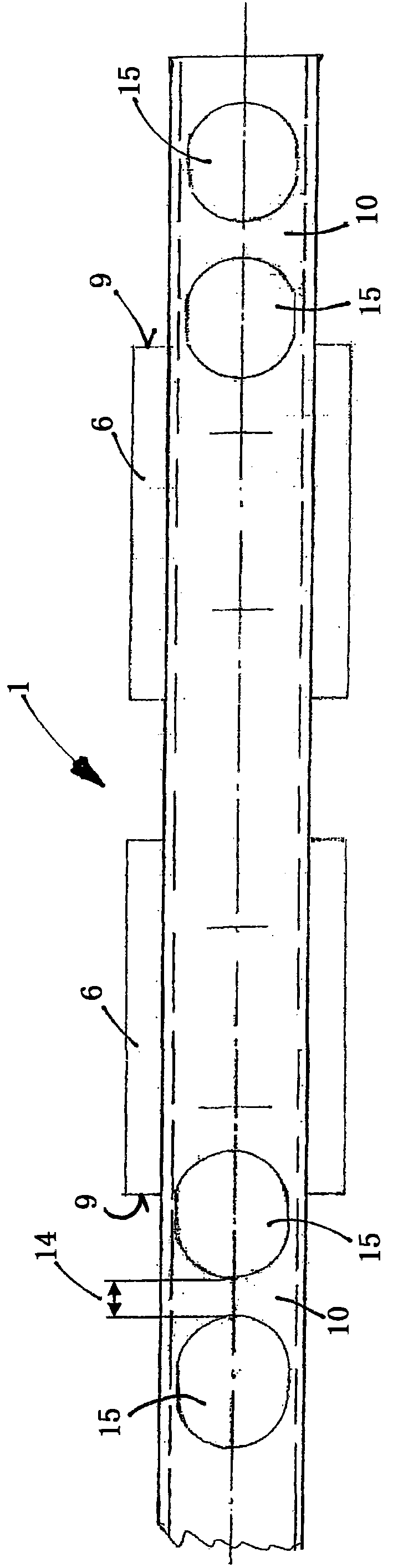

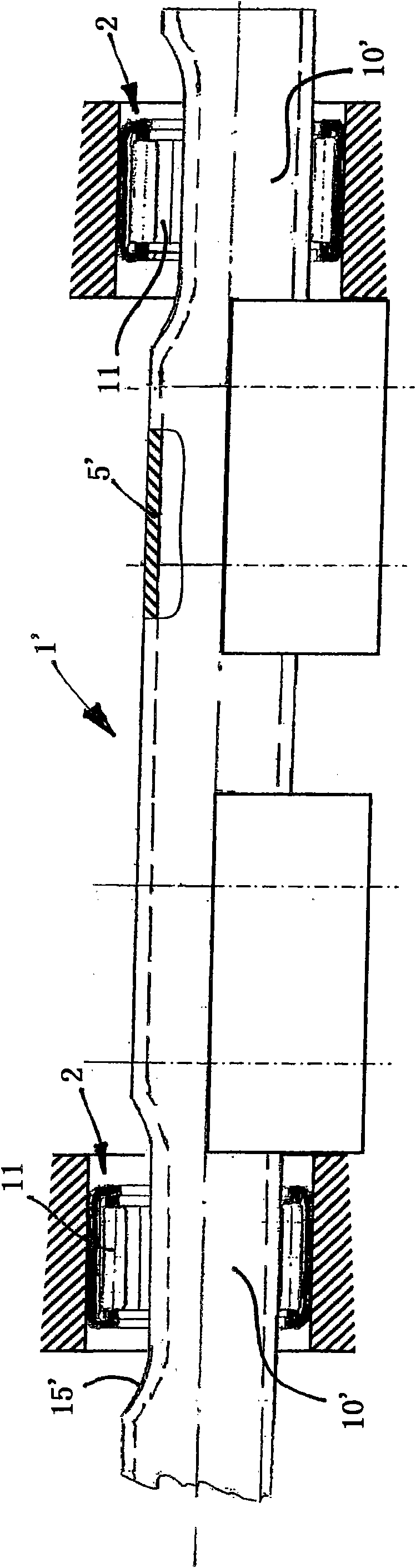

[0016] exist figure 1 and figure 2 Shown in side view or in top view is one of two counter-rotating balance shafts 1 at double the crankshaft speed, which engages with needle bearings 2 to form part of a mass balance transmission for balancing the second stage of an internal combustion engine free inertia force. The balancing shaft 1 accommodated in radial rolling bearing in the bearing housing 3 of the undivided housing 4 of the internal combustion engine consists of a bearing shaft 5 and two unbalanced masses 6 which are screwed to the bearing shaft 5 here by means of screws Combined, wherein, the support shaft 5 is made of a precision tube made of rolling bearing steel. The screw-in points 7 are shown. The screwing of the unbalanced mass 6 onto the matching connecting section 8 of the bearing shaft 5 takes place after the bearing shaft 5 has been pushed into the bearing seat 3 because the diameter of the enveloping circle of the unbalanced mass 6 is larger than Housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com