Triaxial fluxgate probe

A three-axis magnetic and magnetic flux density technology, applied in the field of fluxgate probes, can solve the problems of inconsistent sensitivity, mutual interference, and weak measurement gradient ability of the three axes, and achieve the effects of easy calibration, high sensitivity, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

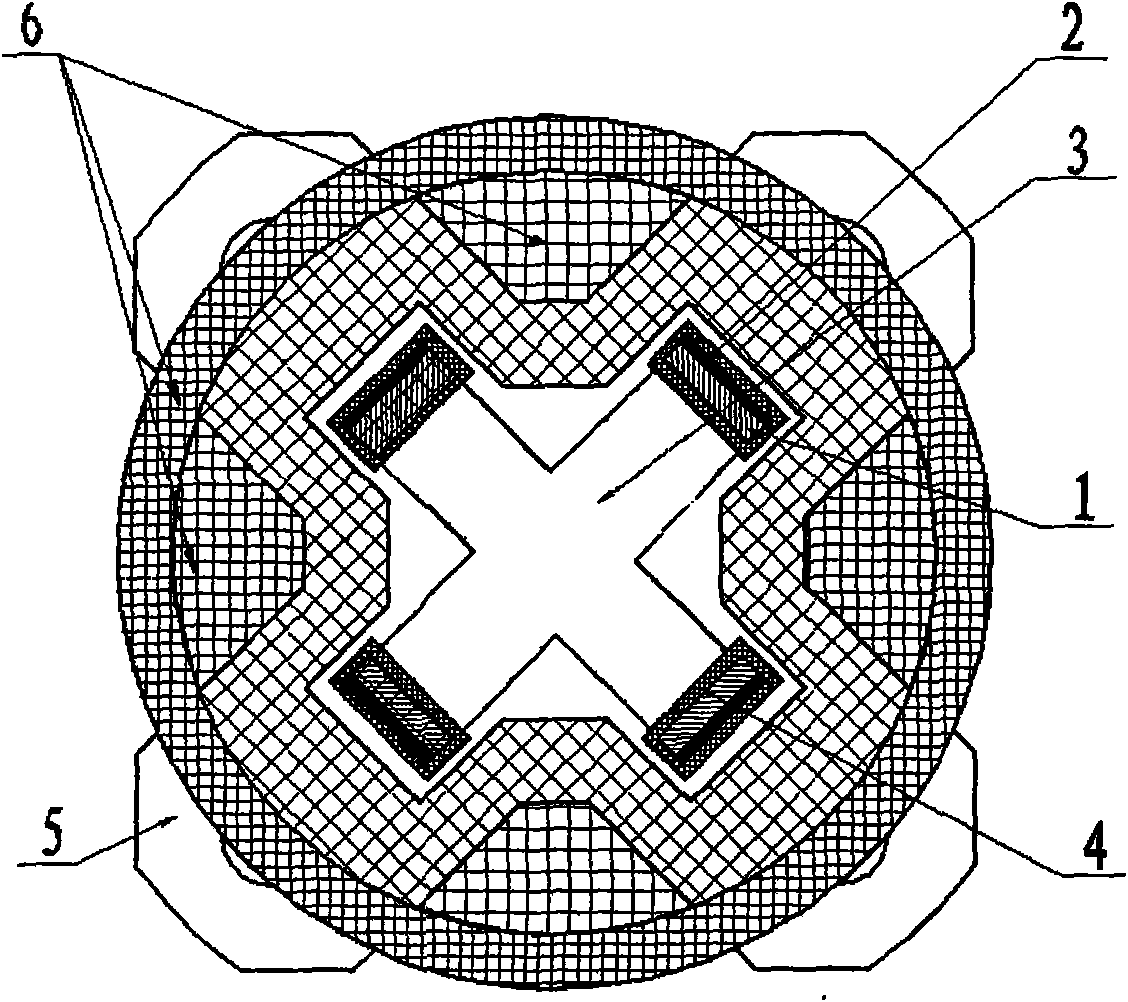

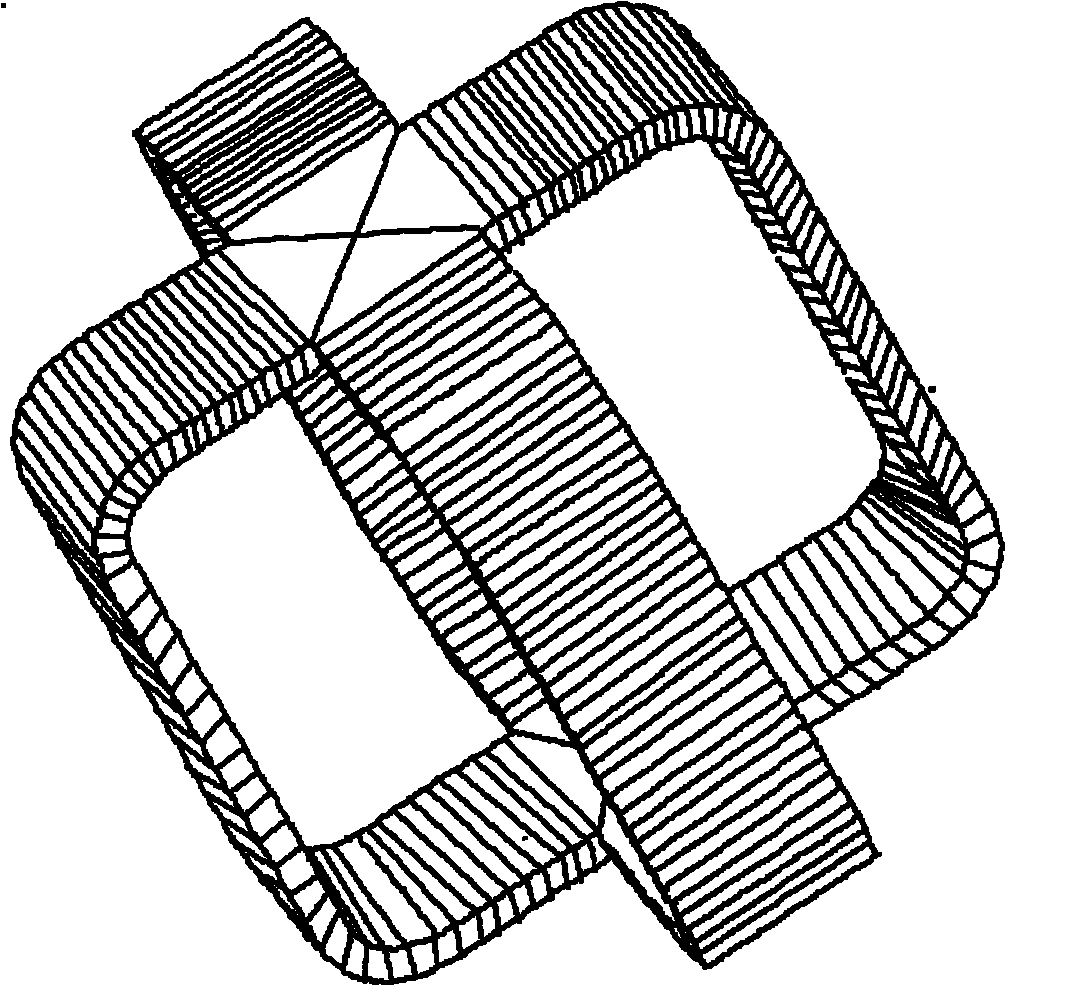

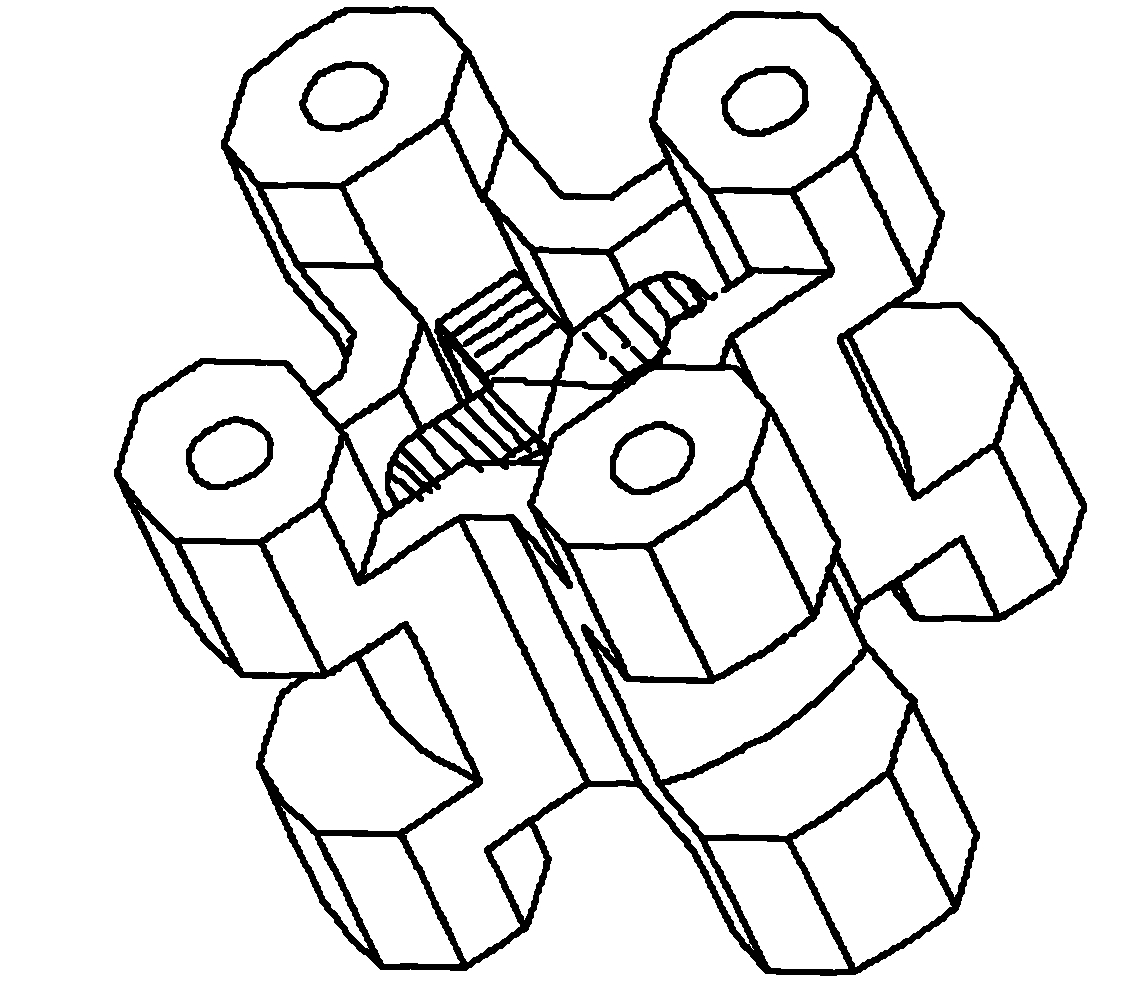

[0013] A three-axis fluxgate probe includes a magnetic core 3, a measuring coil 6, and a measuring skeleton 5. The measuring skeleton 5 is a double hexahedron structure, forming an X axis, a Y axis and a Z axis. There is a cross-shaped cavity in the center of the measuring skeleton 5 for installing the magnetic core 3 . The magnetic core 3 is a cross-shaped skeleton structure, which is composed of two orthogonal rings. The magnetic core skeleton 1 is made of non-magnetic material, the magnetic permeable alloy strip 2 is wound on the outer layer of the magnetic core skeleton 1, and the excitation coil 4 is wound on the Permeable alloy with 2 outer layers. The measurement coil 6 is wound on the measurement skeleton 5; the X-axis, Y-axis, and Z-axis three-axis structure formed by the magnetic core 3 and the measurement skeleton 5 are space-symmetrical and coaxial; the leads of the excitation coil 4 and the measurement coil 6 are all welded on the three-axis Fluxgate probe end fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com