V-process casting molding automatic coating device

A film coating device and automatic technology, applied in the field of casting mold modeling, can solve the problems of uneven heating, waste of materials, low efficiency, etc., and achieve the effect of improving production efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

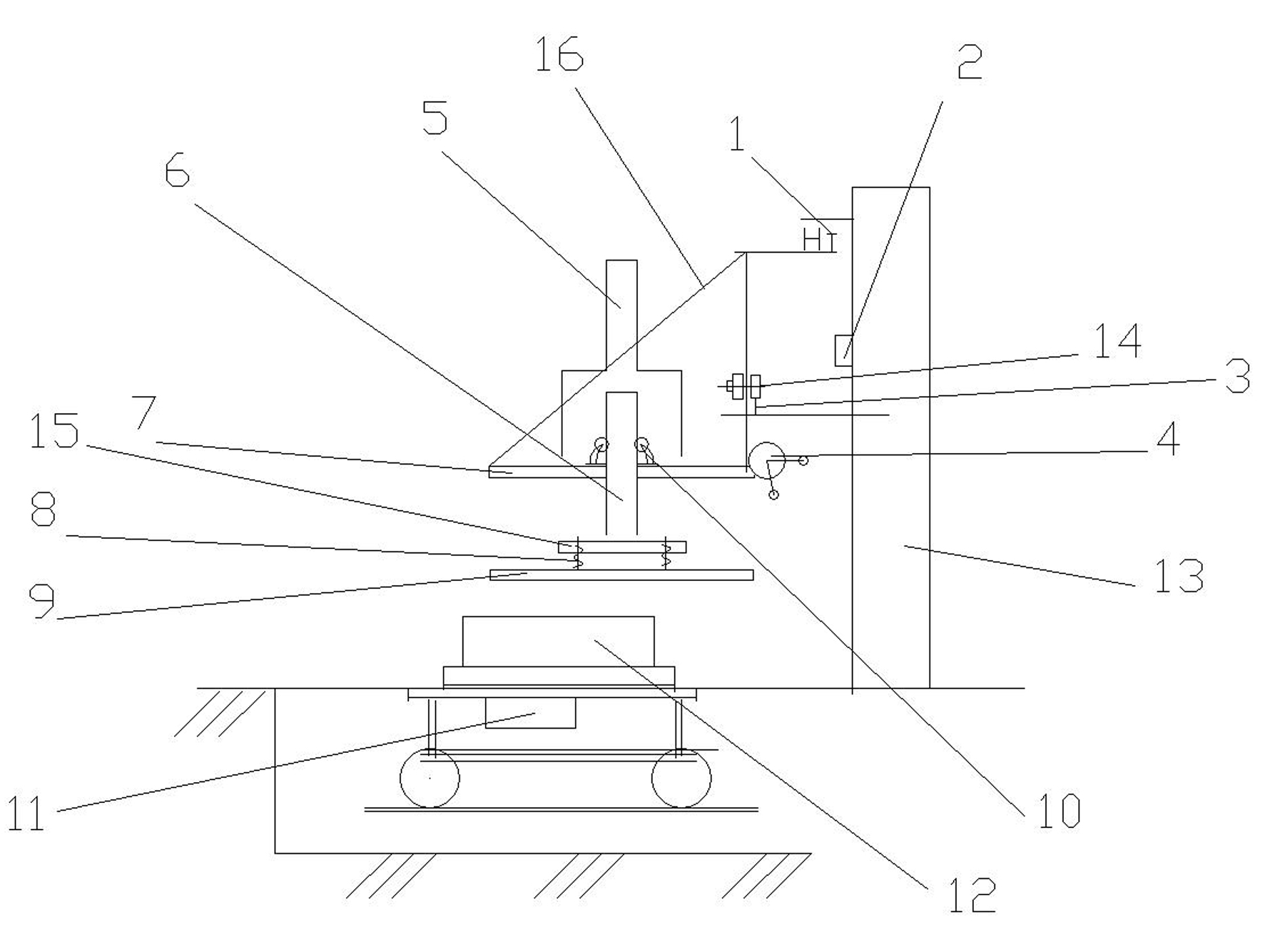

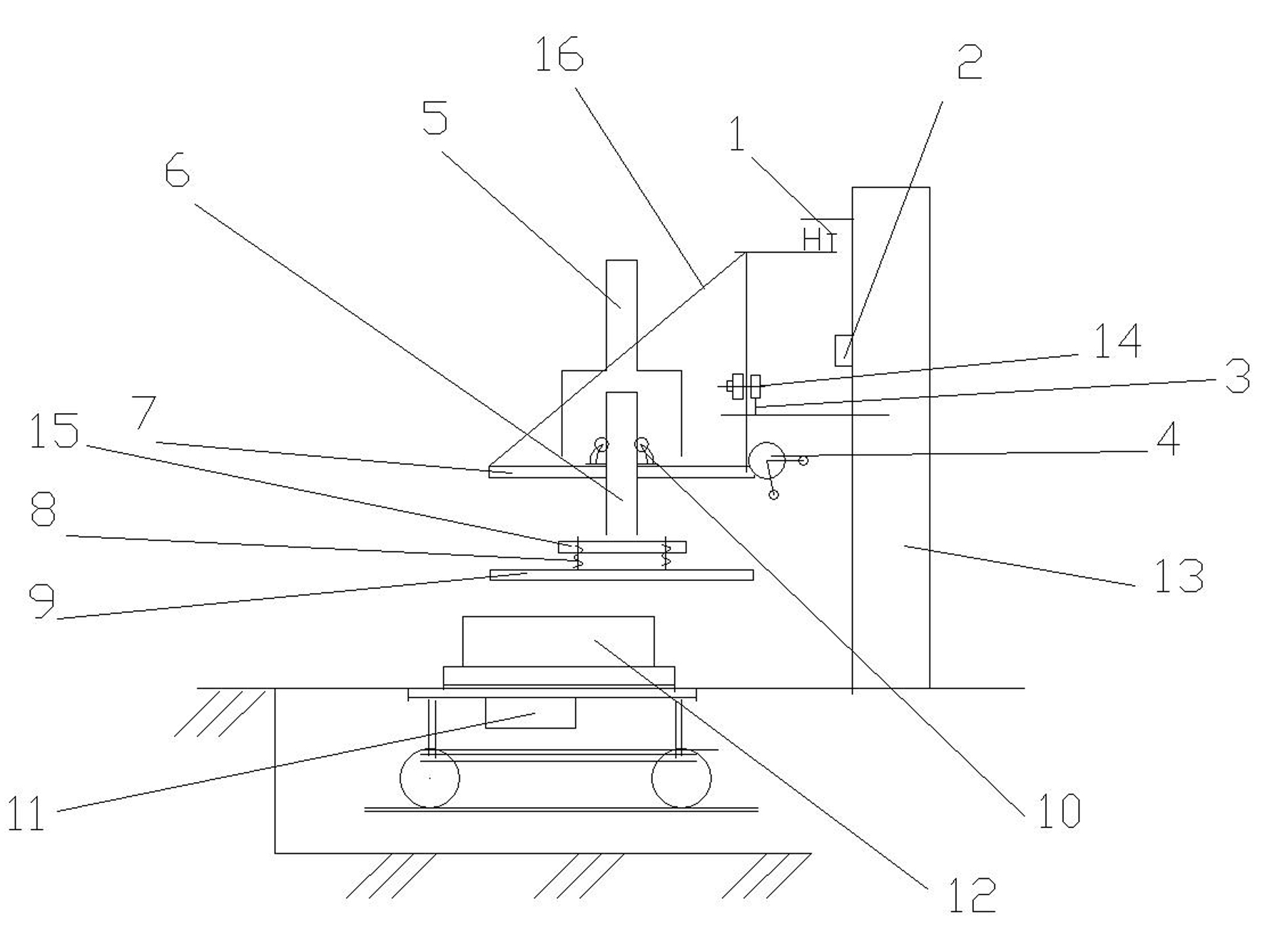

[0016] The embodiment of the present invention includes a lifting vibration trolley 11, a mold 12, a frame leg 13, an upper support wheel rail 1, a pipe cable bridge frame 2, a lower support rail 3 and an automatic film coating frame 16, and also includes an automatic film coating system , the mold 12 is placed on a lifting and vibrating trolley 11 that can be lifted or vibrated; the upper supporting wheel rail 1 and the lower supporting rail 3 are fixedly connected to the frame legs 13, and the automatic film coating The frame 16 is provided with a wheel shaft to move on the upper support wheel rail 1 and the lower support rail 3, and the automatic lamination frame 16 is also provided with a running mechanism 14, which can move forward and backward to adjust the automatic lamination system and the mold. Corresponding to the position, the tube cable bridge 2 is installed on the frame leg 13 to provide cables, electric control cables, high-pressure pipes and the automatic film c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com