Self-lubricating and self-cooling dry cutter and manufacturing method thereof

A self-cooling, dry cutting technology, applied in lathe tools, turning equipment, manufacturing tools, etc., can solve the problems of increased cutting temperature, increased friction, and decreased tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

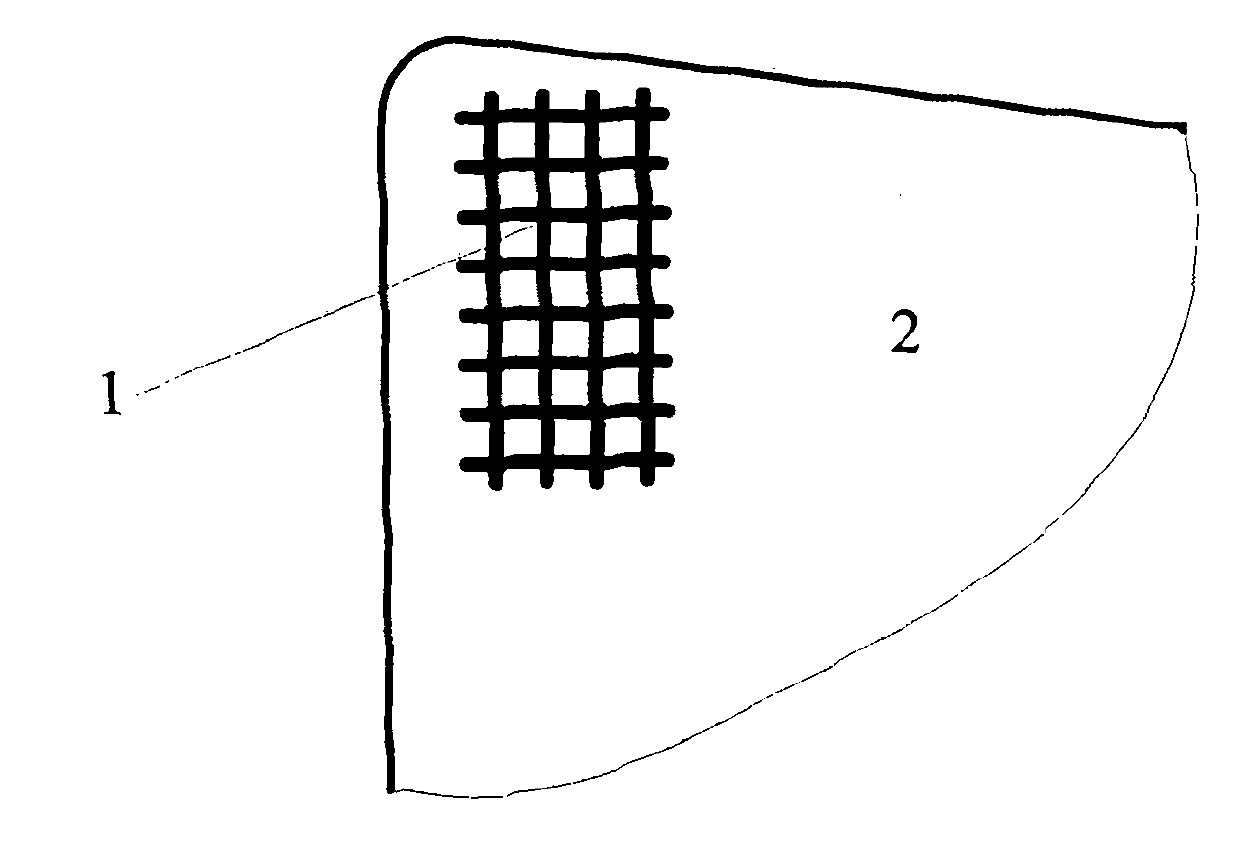

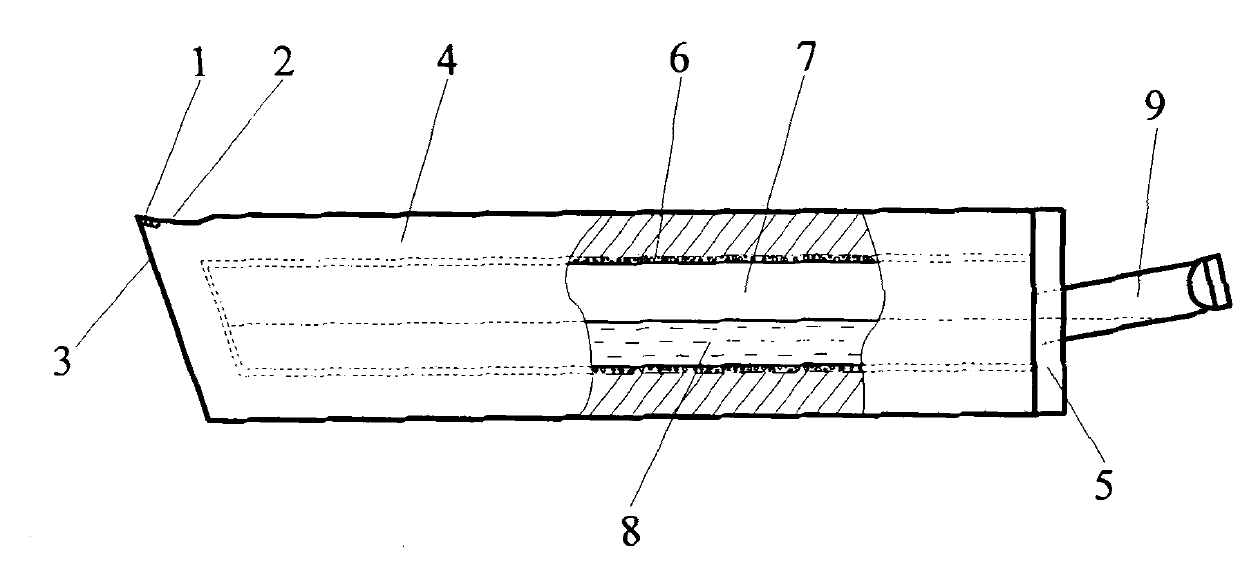

[0016] A self-lubricating and self-cooling dry cutting tool. The material of the tool is high-speed steel. There are multiple micro-friction-reducing grooves 1 filled with solid lubricant in the chip contact area of the rake face 2 of the tool. Self-circulating cooling chamber. Its preparation method is as follows:

[0017] 1. The inner cavity 7 is processed forward from the rear end of the cutter body 4 by using electric discharge machining technology. The cavity 7 is a rectangle with a cross-section of 18×18mm centered along the cutter body section, ensuring that the upper, lower, left, and right wall thicknesses of the cutter cavity are uniform. 6mm, the front end of the cavity 7 is processed to a place close to the front end of the cutter body 4, ensuring that the wall thickness of the front end of the cavity is equivalent to the wall thickness of the side;

[0018] 2. Take a copper plate with a thickness of 5mm and a shape and size of 30×30mm as the rear end cover 5 of...

Embodiment 2

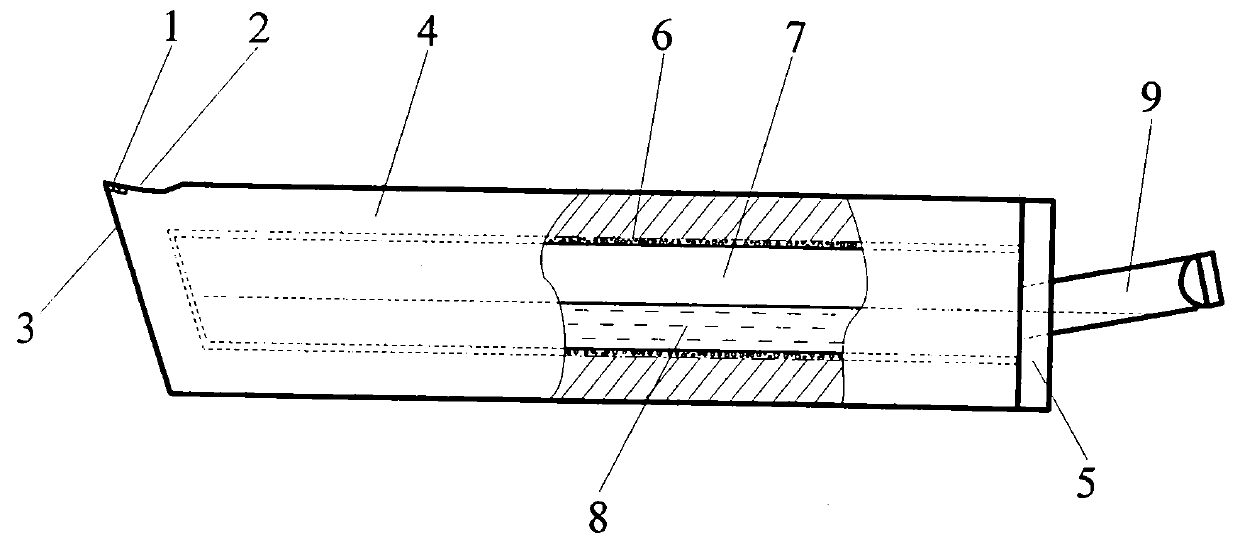

[0024] A self-lubricating and self-cooling dry cutting tool as described in Example 1, the difference is that the working medium of the cooling chamber, the size of the anti-friction groove, and the type of lubricant are different, and its preparation method is as follows:

[0025] 1. The inner cavity 7 is processed forward from the rear end of the cutter body 4 by using electric discharge machining technology. The cavity 7 is a rectangle with a cross-section of 15×15mm centered along the cutter body section, ensuring that the upper, lower, left, and right wall thicknesses of the cutter cavity are uniform. 5mm, the front end of the cavity 7 is processed to a place close to the front end of the cutter body 4, ensuring that the wall thickness of the front end of the cavity is equivalent to the wall thickness of the side;

[0026] 2. Take a copper plate with a thickness of 5mm and a shape and size of 25×25mm as the rear end cover 5 of the cooling chamber of the cutter body, and us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com