cryopump

A cryogenic pump and body technology, applied to pumps, pump devices, pump components, etc., can solve problems affecting the normal operation of cryopumps, high failure rates of cryopumps, maintenance costs, etc., to prolong service life, improve lubrication effect, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

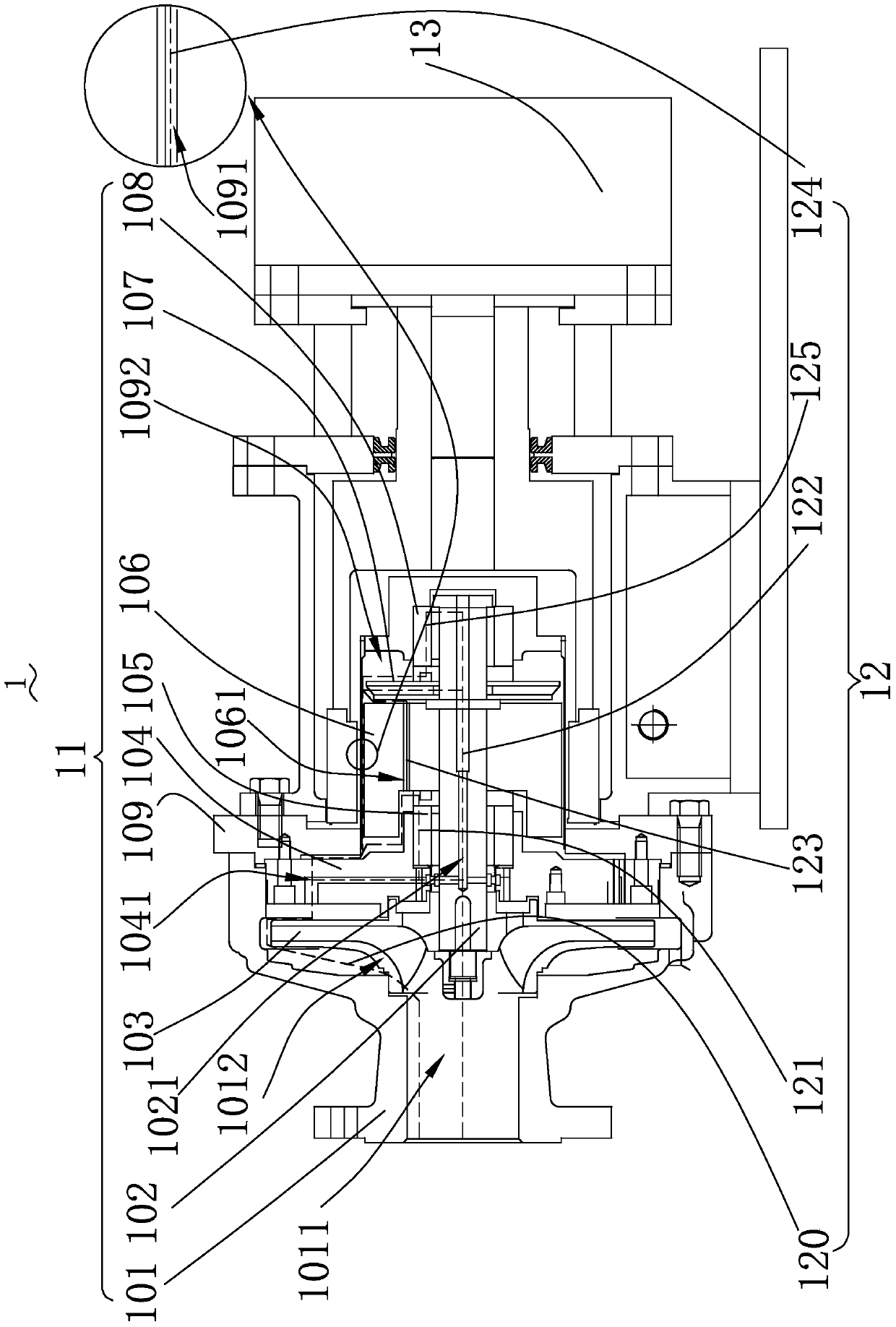

[0013] see figure 1 , is a structural schematic diagram of the cryopump of the present invention. The cryopump 1 includes a pump body 11 , a self-lubricating system 12 and a motor 13 . The self-lubricating system 12 is arranged in the pump body 11 . The motor 13 is connected with the pump body 11 .

[0014] The pump body 11 includes a housing 101 with a housing space, a main shaft 102 accommodated in the housing 101 , an impeller 103 and a rear cover 104 arranged in sequence from the inlet 1011 of the pump body 11 to the direction of the motor 13 , the first bearing 105 , the inner magnetic coupling 106 , the booster impeller 107 , the second bearing 108 and the spacer 109 .

[0015] The impeller 103, the rear cover 104, the first bearing 105, the inner magnetic coupling 106, the booster impeller 107 and the second bearing 108 are respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com