Method of fabricating and encapsulating mems devices

A technology for encapsulating films and microstructures, which is applied in the direction of assembling microstructure devices, microstructure devices, and manufacturing microstructure devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The drawings used for illustration are not strictly to scale, but generally illustrate the framework and principles of the invention. In the following description, reference is made to the accompanying drawings which form a part hereof, showing by way of illustration preferred embodiments of the invention. It is to be understood that other embodiments may be utilized and structural changes may be made without departing from the scope of the present invention.

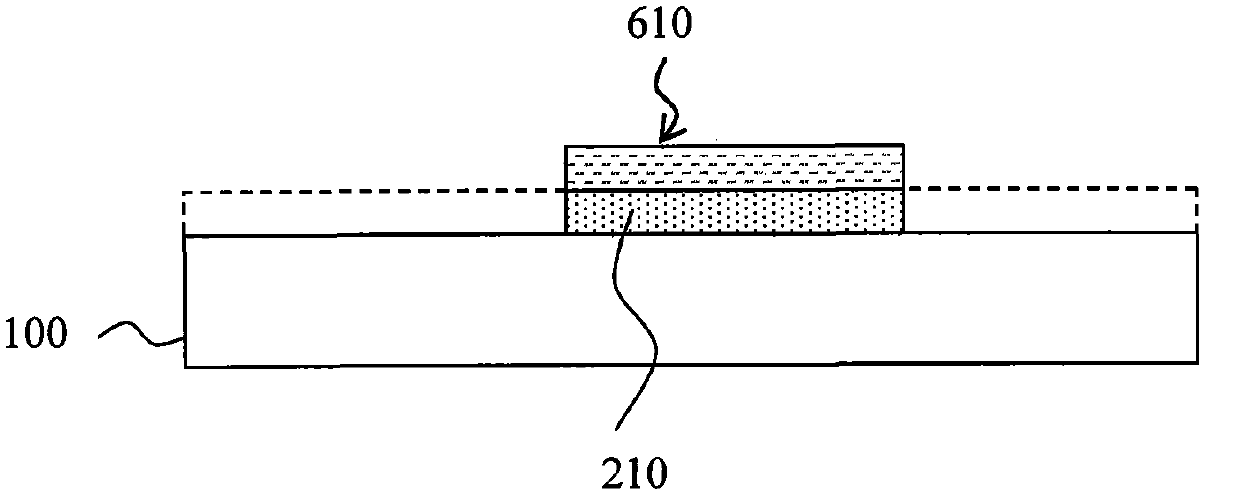

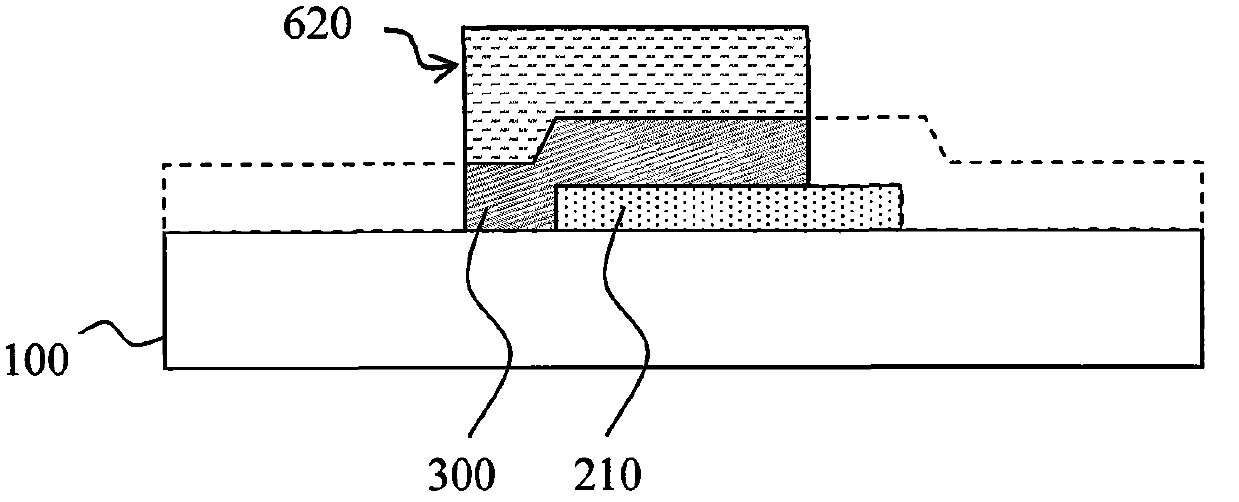

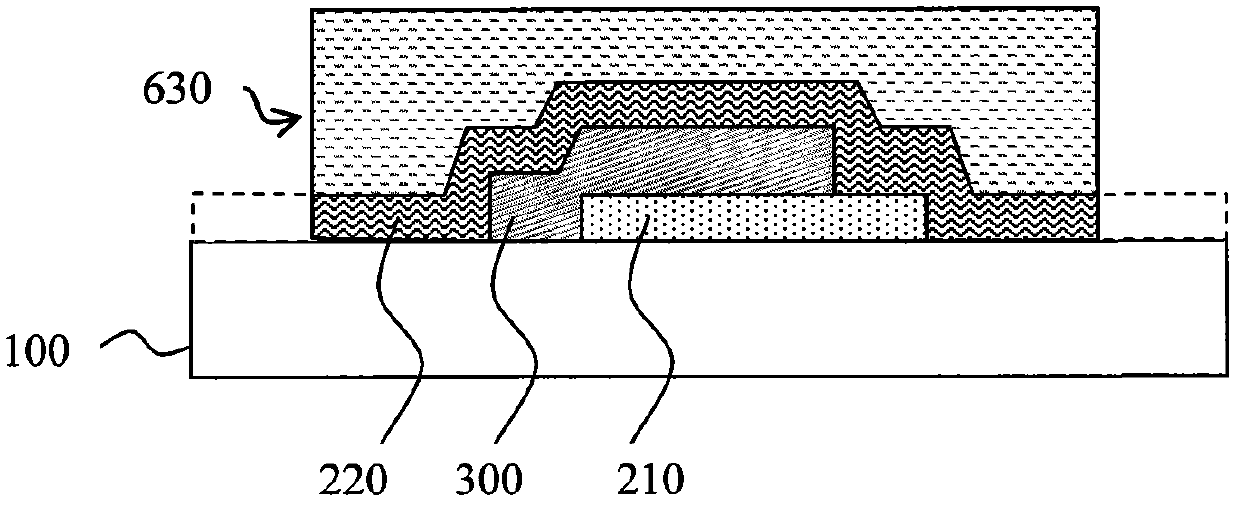

[0027] Figure 1a , 1b , 1c, 1d, 1e, 1f show in cross-sectional views the use of the first sacrificial carbon film 210 and the second sacrificial carbon film 220 as double sacrificial layers to assemble and package the structural element 300 suspended on the substrate 100 in sequential basic steps A basic embodiment of the method is disclosed. like Figure 1a As shown, the steps of depositing the first sacrificial carbon film 210 are as follows: placing the substrate 100 in the reactor chamber, introducing a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com