Method for preparing carbon nanotube linear structure

一种碳纳米管线、碳纳米管的技术,应用在纳米技术、纳米技术、化学仪器和方法等方向,能够解决碳纳米管丝机械强度及韧性限制、限制应用等问题,达到好机械强度及韧性、直径可控、应用范围广的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The method for preparing the carbon nanotube linear structure provided by the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

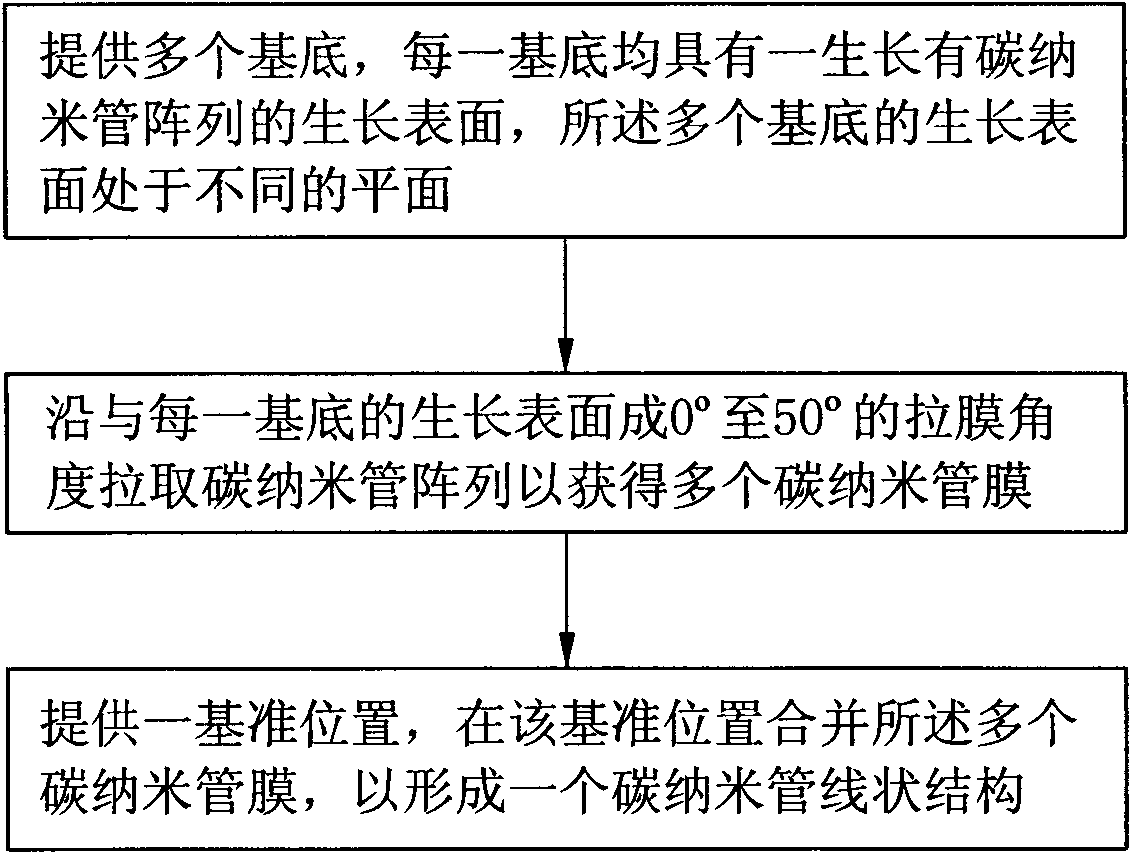

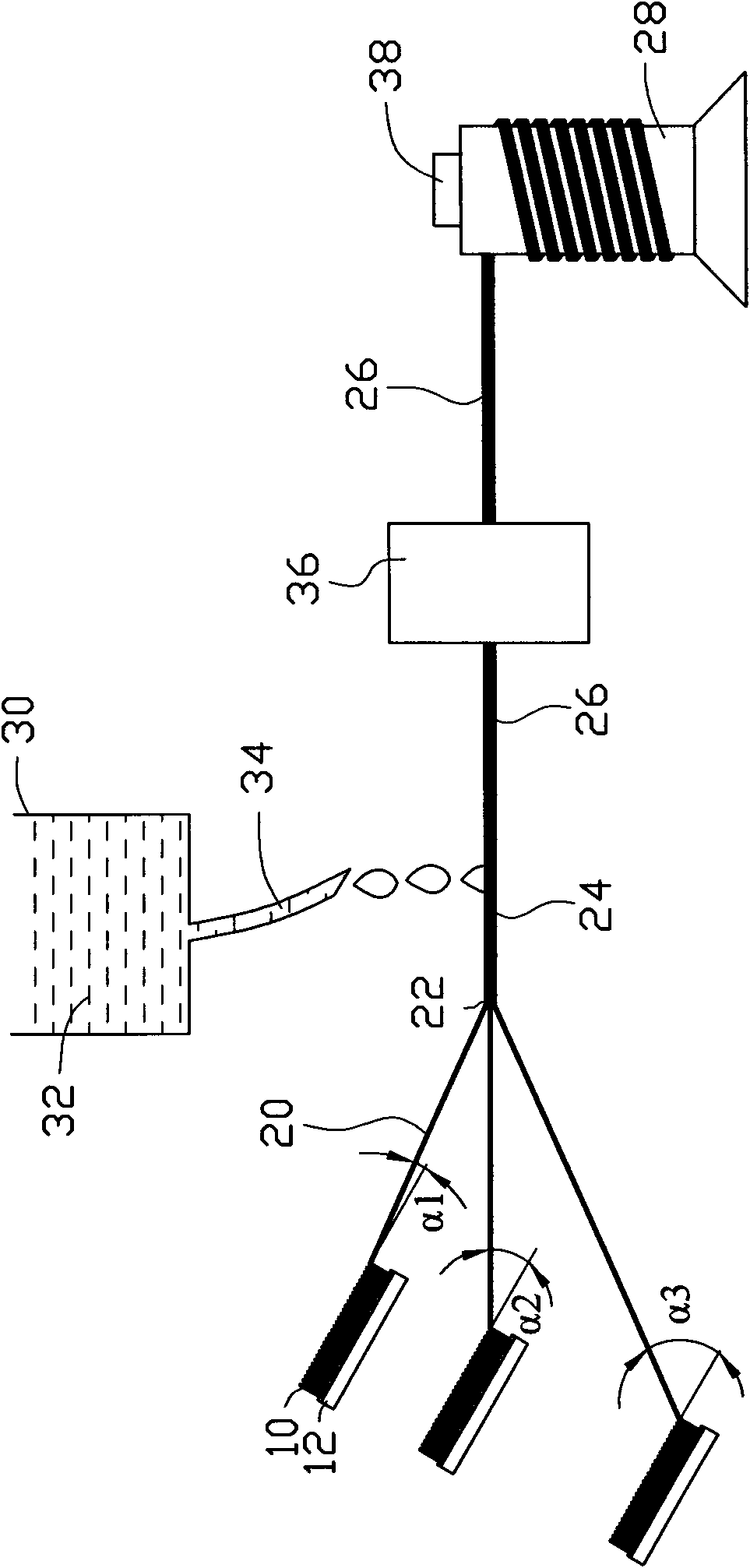

[0015] Please also refer to figure 2 , image 3 and Figure 4 , the first embodiment of the present invention provides a method for preparing a carbon nanotube linear structure, which includes the following steps:

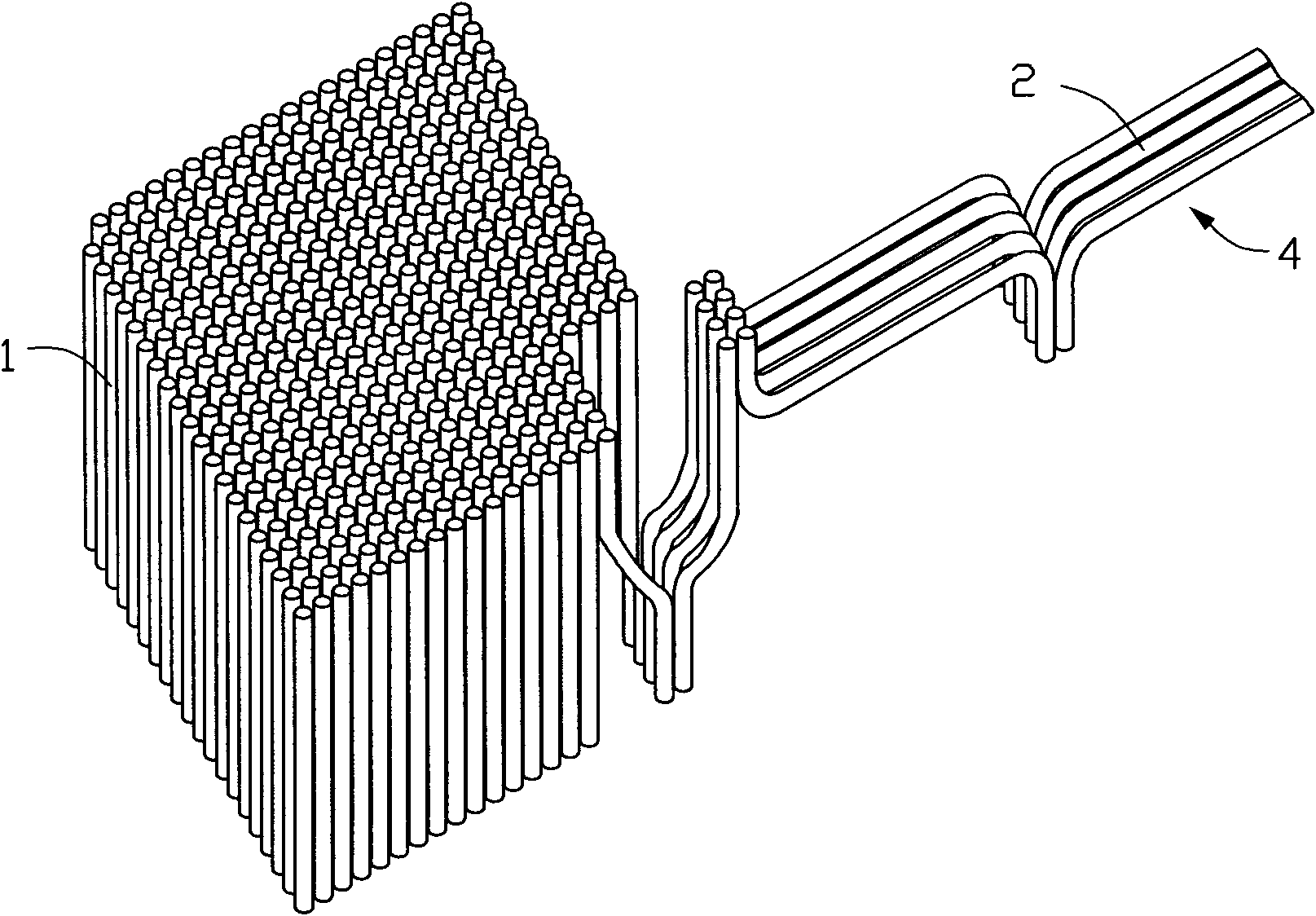

[0016] Step S101: providing a plurality of substrates 12, each substrate 12 has a growth surface 122 on which the carbon nanotube array 10 is grown, and the growth surfaces 122 of the plurality of substrates 12 are in different planes;

[0017] Step S102: pulling the carbon nanotube array 10 along a film-drawing angle of 0° to 50° with the growth surface 122 of each substrate 12 to obtain a plurality of carbon nanotube films 20;

[0018] Step S103 : providing a reference position 22 at which the plurality of carbon nanotube films 20 are combined to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com