Device for producing weakly alkaline negative potential electrolyzed water and electrolysis water dispenser

A negative potential, electrolyzed water technology, used in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, complicated control circuit, and long time to produce electrolyzed water. To achieve the effect of simple structure, fast and effective preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

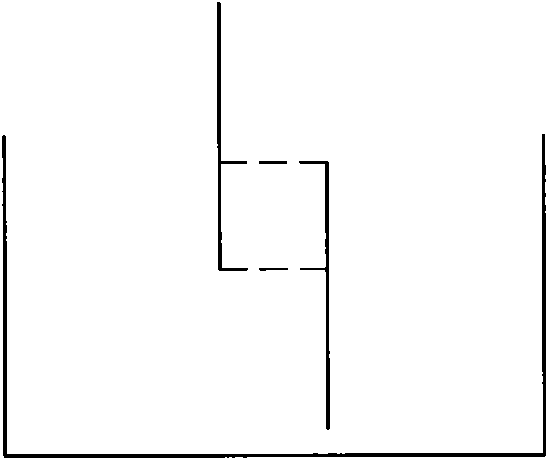

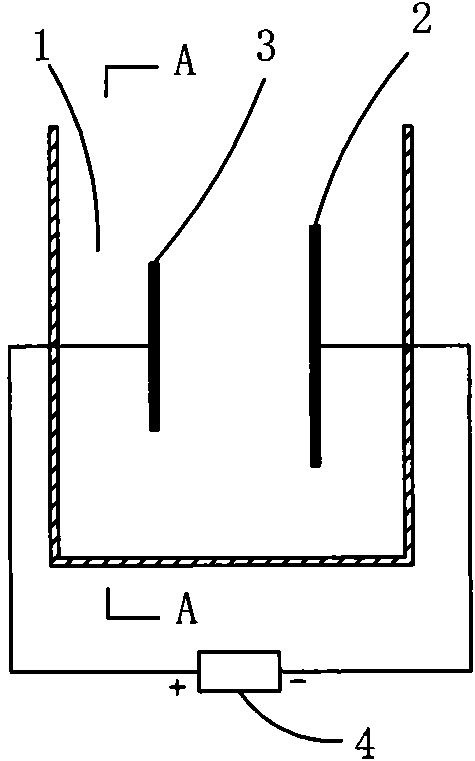

[0041] The weakly alkaline negative potential electrolyzed water preparation device of this embodiment, such as image 3 and Figure 4 As shown, it includes an electrolytic cell 1 without a diaphragm, negative and positive electrodes 2 and 3 placed in the electrolytic cell 1 and a DC pulse power supply 4 connected to the negative and positive electrodes 2 and 3 . The electrolytic cell 1 is made of non-conductive material, and the cathode and anode electrodes 2 and 3 are flat plates and are inert electrodes made of inert materials such as platinum, iridium or ruthenium plated on the surface of the titanium base. The cathode and anode electrodes 2 and 3 It is placed in the electrolytic tank 1 parallel to the side wall of the electrolytic tank 1 . The surface area of the negative electrode 2 is greater than the surface area of the positive electrode 3, wherein the ratio of the surface areas of the positive electrode 3 and the negative electrode 2 is 1:1.5, and the positive e...

Embodiment 2

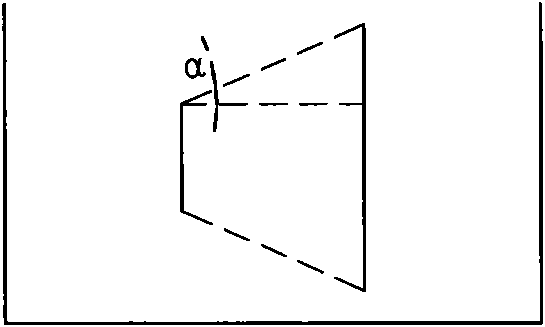

[0043] The device for producing weakly alkaline negative potential electrolyzed water in this embodiment is an improvement on the basis of Embodiment 1, as Figure 5 and Figure 6 As shown, except that it is the same as that of Embodiment 1, the difference is that the projected areas of the cathode and anode electrodes 2 and 3 in a plane perpendicular to their geometric center line are basically the same, but the anode electrode 3 is formed with uniform and densely distributed through holes. 5. The ratio of the surface area of the positive electrode 3 to the negative electrode 2 is 1:5 (the surface area of the positive electrode in this embodiment refers to the remaining surface area after the through hole 5 is removed). At this time, according to experimental calculation, the ideal range of the distance between the anode electrode 3 and the cathode electrode 2 is 10mm-450mm.

Embodiment 3

[0045] This embodiment is an improvement on the basis of Embodiment 2, as Figure 7 As shown, except that it is the same as the second embodiment, the difference is that the through holes 5 on the positive electrode 3 are larger and denser, so that the ratio of the surface area of the positive electrode to the negative electrode is 1:8 (the positive electrode of this embodiment The surface area refers to the remaining surface area after the through hole 5 is removed). At this time, according to the experimental calculation, the ideal range of the distance between the anode electrode 3 and the cathode electrode 2 is 4mm-600mm.

[0046] The weak alkaline negative potential electrolyzed water production device in the above three embodiments and the non-diaphragm electrolyzed water device with the same surface area of the cathode and anode electrodes were respectively subjected to the electrolyzed water preparation experiment. The main experimental conditions are:

[0047] 1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com