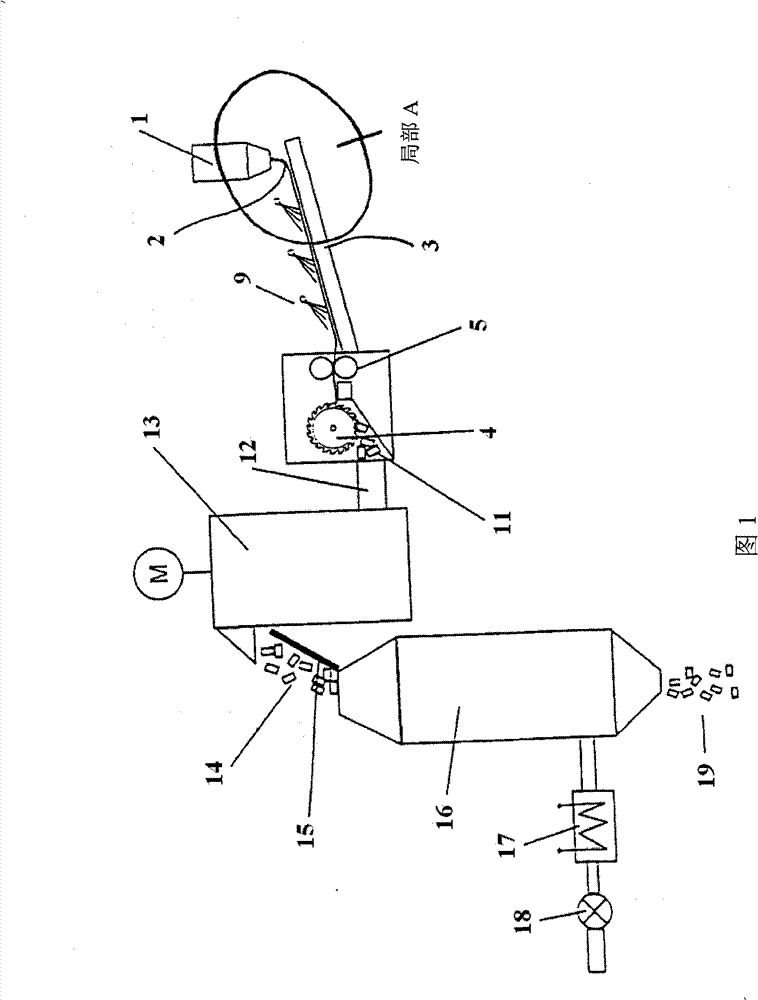

Extrusion granulation method and device, and granulate produced therefrom

A granulation device and a technology for a strand, which is applied to the field of particles prepared by a method, can solve the problems of strand tearing, difficulty in adjusting thermal conditions, aggregation, etc., and achieve the effect of size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

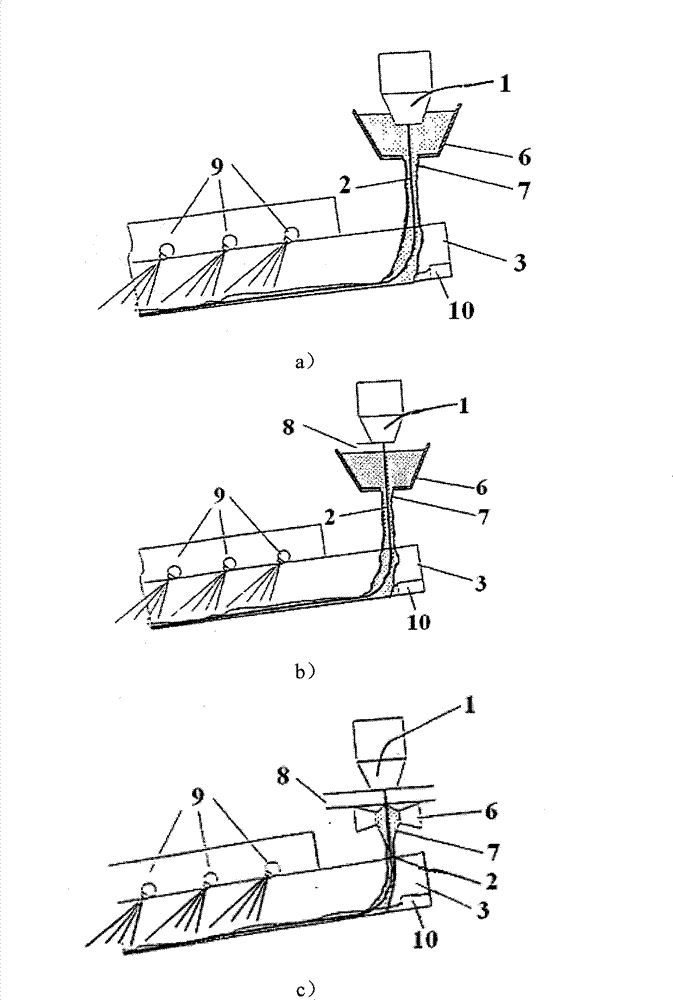

Method used

Image

Examples

Embodiment 1

[0068] At a melt temperature of 280°C, a polyethylene terephthalate copolymer having 2% isopropyl Alcohol (IPA) with a melting temperature of 245° C. by DSC and an intrinsic viscosity of 0.6 dl / g. The die opening at the exit has a diameter of 2 mm and a length of 1 mm; 7 mm before the exit, the die has a diameter of 14 mm. Therefore, the following main data were generated: l / d=0.5; F / f=49; v aus = 261 m / min; v aus / f=83m / (minute×mm 2 ).

[0069] The die temperature was 230°C. After reaching a distance of 4mm from the die, the strands are subjected to water at a temperature of 84°C and are fed through a 3.2m long discharge chute, also subjected to water at a temperature of 84°C To the granulation device. The moving speed of the strand was 200 m / min, and the particles with a length of 3 mm and a weight of 15 mg were obtained. The residence time until particle formation was about 1 second.

[0070] Through a 1.2 m long feed pipe, the granules and the water were conveyed t...

Embodiment 2

[0072] Immediately after exiting the granule dryer, the granules of Example 1 were quenched, vacuum dried at 60°C, and then crystallized at 170°C for 20 minutes in a vessel without stirring.

[0073] The granules flowed freely, 88% of the granules were in the form of individual particles and 12% of the granules formed small agglomerates, wherein, in each case, the agglomerations occurred at the cut surfaces of the granules.

[0074] The flakes with a thickness of 2 μm showed a crystal structure with a crystal diameter of about 5 μm at the particle center, and the average crystal diameter became smaller toward the outside. At the edge, there is a layer with a thickness of about 40 μm in which the individual crystals are so small that, given the available sample thickness, the structure is no longer visible, resulting in a crystal diameter of <1 μm. Therefore, the nucleation density in the surface layer with a thickness of about 40 μm is higher than that at the center by more th...

Embodiment 3

[0080] The same polyethylene terephthalate copolymer as in Example 1 was extruded at a melt temperature of 276° C. at 200 kg / h through two dies. The die opening at the exit had a diameter of 5 mm and a length of 1 mm; 5 mm before the exit, the die had a diameter of 18.3 mm. Therefore, the following main data were produced: l / d=0.2; F / f=13.4; v aus = 70 m / min; v aus / f=3.5m / (minute×mm 2 ).

[0081] The die temperature was 260°C. After leaving the die at a distance of 4-5mm, the strands are subjected to water at a temperature of 84°C and then fed through a 2.2m long discharge chute also subjected to water at a temperature of 84°C To the granulation device. The moving speed of the strand was 250 m / min, and the particles with a length of 3 mm and a weight of 20 mg were obtained. The residence time until particle formation was about 0.5 seconds. Through a 1.2 m long feed pipe, the granules and the water were conveyed to a granule dryer where the granules were separated from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com