Heat dissipation structure of high-power light-emitting diode (LED) illuminating lamp

A technology of LED lighting and heat dissipation structure, which is applied in the field of electronics, can solve the problems of unsuitable high-power LED heat dissipation and development, poor compatibility of LED radiators, small contact heat transfer area, etc., to achieve lower temperature, compact structure, and meet heat dissipation requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

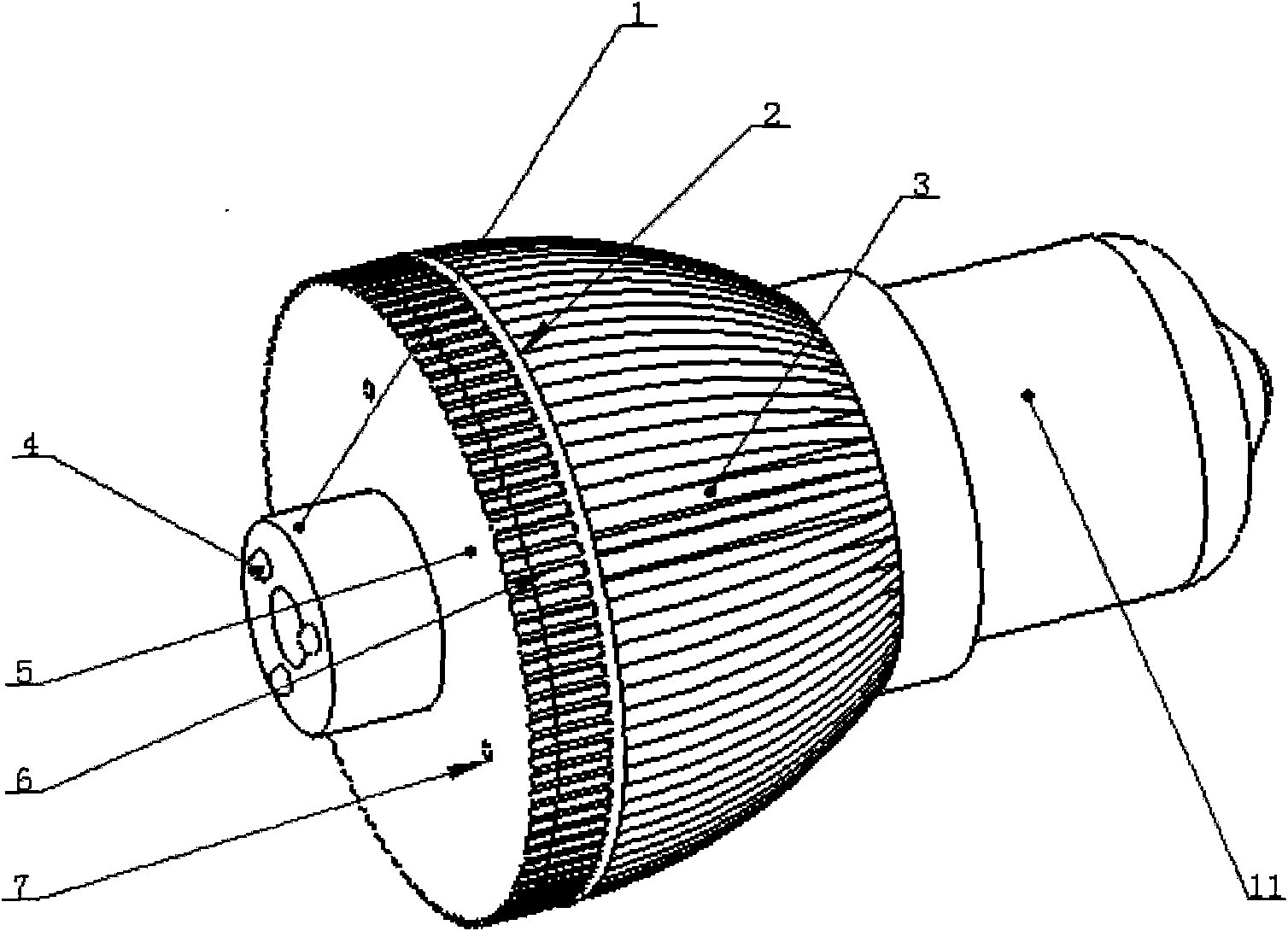

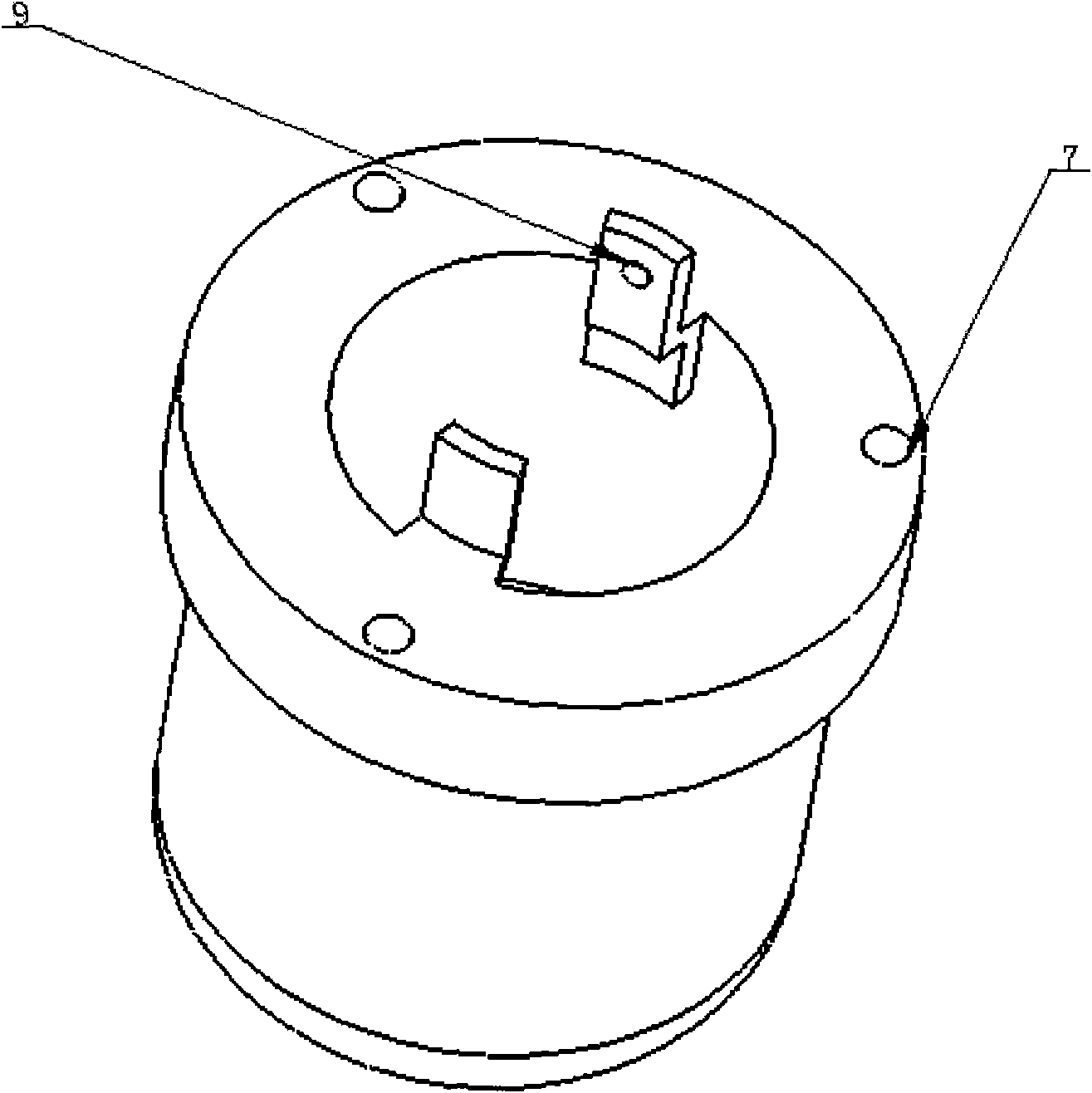

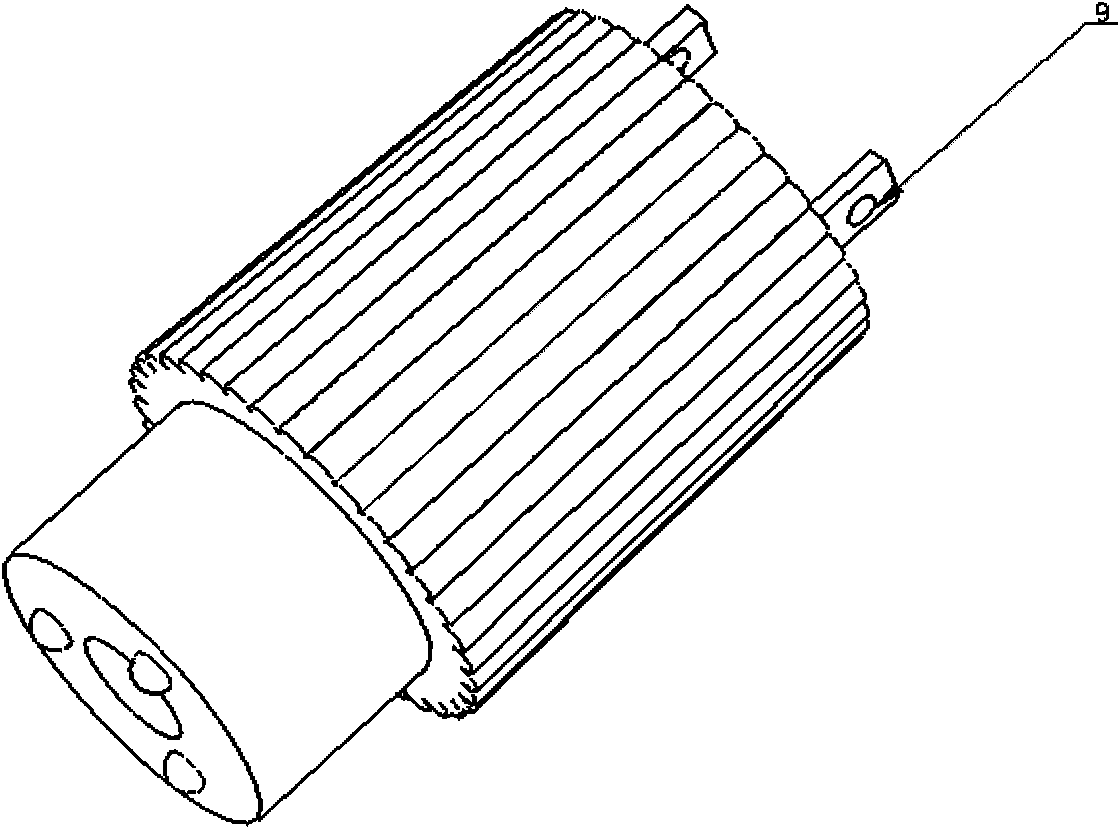

[0020] Depend on Figure 1-Figure 5 As shown, the present invention includes LED chip base column 1, heat dissipation shell 2, fixed gasket 5 and screw socket 11. In order to quickly reduce the temperature of high-power LED 4, LED chip base column 1 needs to be inserted into heat dissipation shell 2, and The contact curved surface has a wavy surface, and it is filled with a thermally conductive adhesive material, such as thermally conductive silica gel, so that it is in close contact with the inner surface of the heat dissipation shell 2, and a high-power LED4 is fixed on the front end surface of the cylindrical LED chip base column 1 , the chip base and the heat dissipation shell are made of a heat conductor.

[0021] The heat conductor is: aluminum, copper or a non-metallic material with high heat conduction efficiency that meets heat dissipation requirements. Because the power of the high-power LED 4 is different, its calorific value is also different, so one of the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com