Hierarchical cavity type solar heat absorber and heat exchange system

A technology of solar heat absorber and heat exchange system, which is applied in the direction of solar thermal power generation, solar thermal devices, and mechanical power generated by solar energy, etc., which can solve the problems of excessive heat flux design, limit wall thickness, and reduce unit efficiency, etc., to achieve Prolong the effective working time, increase the pressure level of the working medium, and reduce the effect of heat radiation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

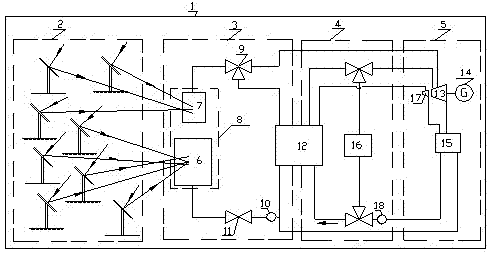

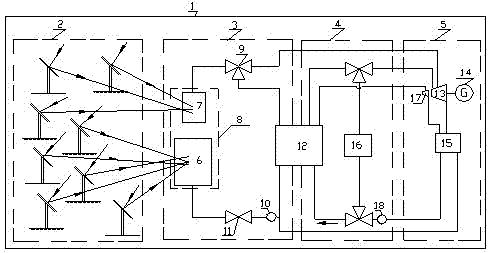

[0017] Such as figure 1 Shown is a specific embodiment 1 of the present invention, a solar thermal power plant 1 according to the present invention. Here, the solar thermal power plant 1 is composed of a solar concentrating field 2 , a solar steam circuit 3 , a fossil fuel steam circuit 4 and a conventional power generation system 5 . In this power generation circuit, there are a plurality of solar reflector concentrating fields 2 and a plurality of solar heat absorbers 8, and the heat absorbers of the solar heat absorbers 8 include independent first-stage heat absorbers 6 and second-stage heat absorbers 7, that is, the first-stage heat absorber 6 arranged with an evaporation heating surface and the second-stage heat absorber 7 arranged with an overheating heating surface, and the evaporation heating surface and the overheating heating surface are connected by a steam drum. The evaporating heating surface heats the feed water to generate saturated steam, and sends the satura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com