Filter compound material, method for the production thereof and flat filter elements made of the filter compound material

A composite material, filter element technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve problems such as cracks and delamination of filter membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

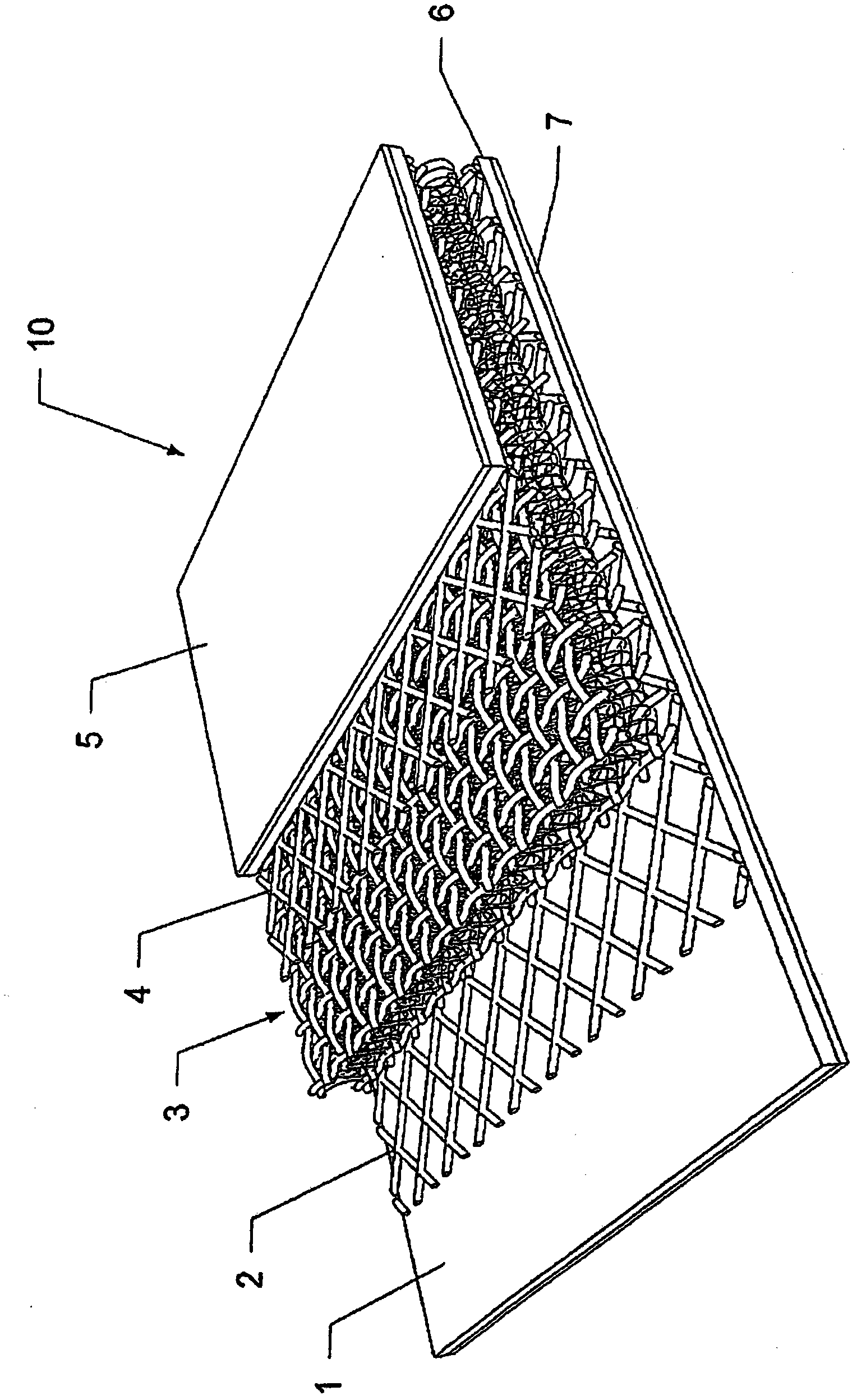

[0037] exist figure 1 The filter composite 10 shown in includes a first filter membrane 1, a first bonded web 2 made of a thermoplastic polymer, a drainage fabric 3, a second The mesh 4 and a second filter membrane 5 are bonded. The filter membranes 1 and 5 are connected to the drainage fabric 3, for example by thermal or ultrasonic welding, adhesive bonding, machine sewing or mechanical clamping. Connecting lines or seams are indicated schematically by reference numerals 6 , 7 .

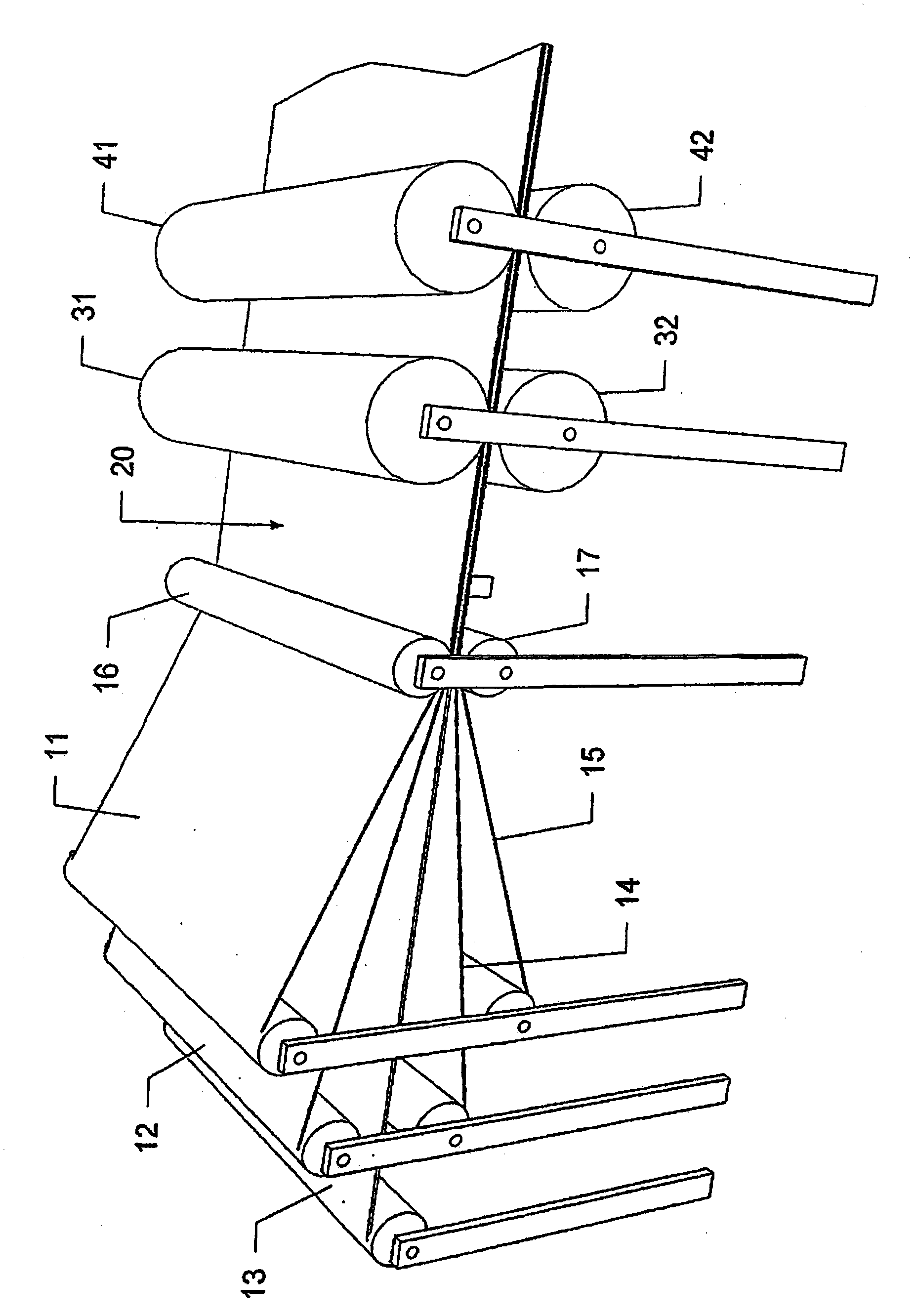

[0038] exist figure 1 The filter composites shown in figure 2 A continuous strip material 20 is produced by the apparatus schematically shown in . To this end, a first filter membrane belt 11, a first bonded mesh belt 12, a drainage fabric belt 13, a second bonded mesh belt 14 and a second filter membrane belt 15 are respectively placed on a plurality of storage rolls. A pair of press rollers 16, 17 are combined in a belt-like stack. The stack passes through a pair of heated rollers 31 , 32 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com