Method for producing a core composite with double-sided surface layers

A technology for composite parts and covering layers, applied in the field of manufacturing core composite parts, can solve the problems of poor aerodynamic performance, reduced load capacity of mechanical structure, difficult winding and/or laying of covering layers, etc., to achieve the effect of aesthetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

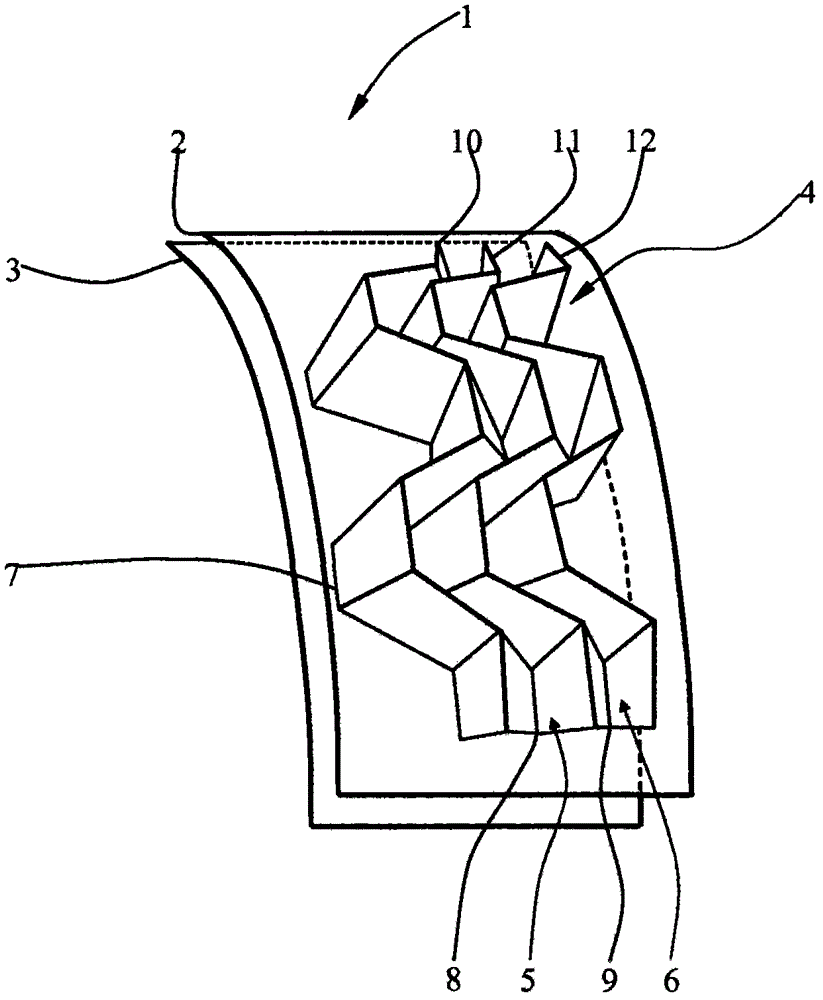

[0039] figure 1 A core composite part with a sandwich structure manufactured according to the method of the present invention is shown, which has a curvature in the spatial direction. The two covering layers covering both sides of the folded honeycomb core are only shown in outline, but the remaining parts are shown as transparent so as to expose the internal structure of the folded honeycomb core.

[0040] The core composite part 1 has an upper covering layer 2 and a lower covering layer 3, and a folded honeycomb core 4 is arranged between these covering layers. The covering layers 2, 3 and the folded honeycomb core 4 are all curved in the spatial direction. In principle, this method can be used to produce flat, single or double (spherical) curved core composite parts with very high load capacity. The folded honeycomb core 4 has a plurality of (drain-) channels 5, 6 arranged in parallel, penetrating and extending trapezoidally. The channels 5, 6 are defined by base lines 7 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com