Buffer strip for blanking port of belt conveyor

A belt conveyor and blanking port technology, applied in the field of buffer bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

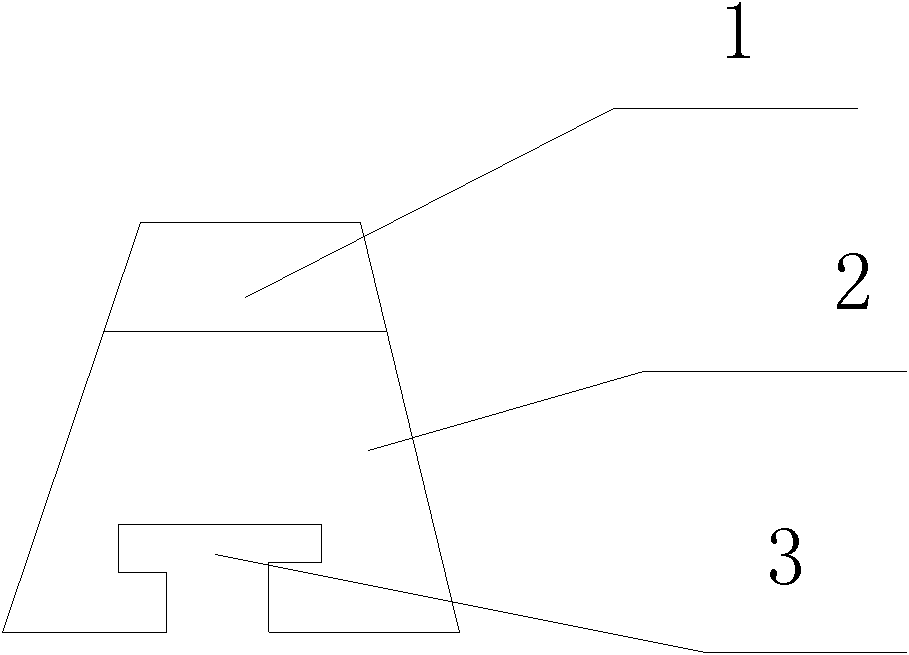

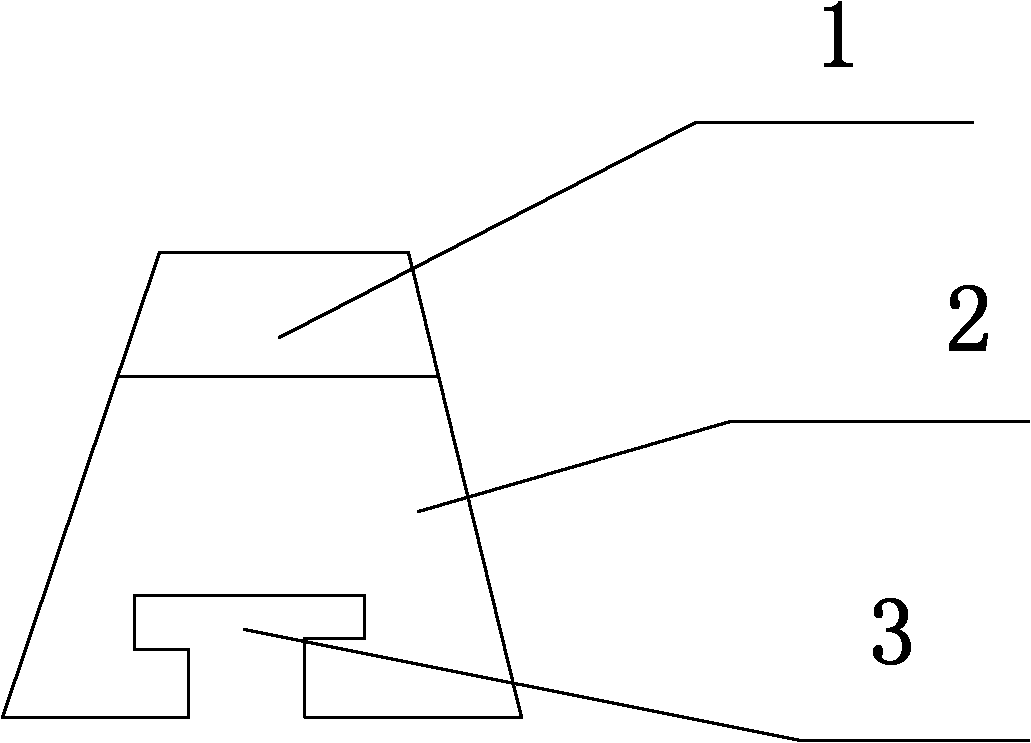

[0015] As shown in the figure, in order to solve the above-mentioned technical problems, the present invention provides a buffer strip for the discharge port of a belt conveyor, which includes a metal profile 3, a plate body 1 and a buffer body 2, and the plate body 1 is passed through an adhesive or Other methods are fixedly arranged on the upper surface of the buffer body 2, and the metal profile 3 is fixedly arranged on the lower surface of the buffer body 2 by embedding. The present invention improves the rigidity of the buffer bar through the combination of the buffer body 2 and the metal structure, so that the buffer bar can withstand relatively large impacts during the operation of the equipment, and provide comprehensive support for the belt, thereby greatly improving the impact resistance of the belt performance, which prolongs the service life of the belt; and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com