Positive-negative integrated conveying system device of multifunctional pump

A conveying system and multi-functional technology, which is applied in conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the difficulty of controlling the discharge speed of the down-drawing warehouse pump, the low efficiency of conveying compressed air and conveying dry ash, and the failure of pipe plugging And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

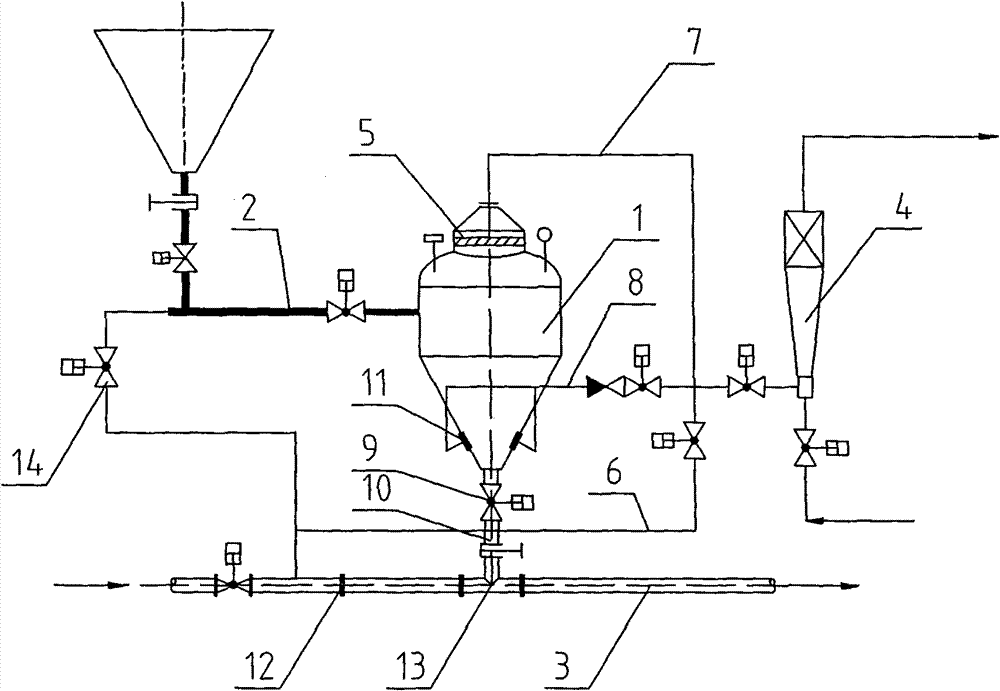

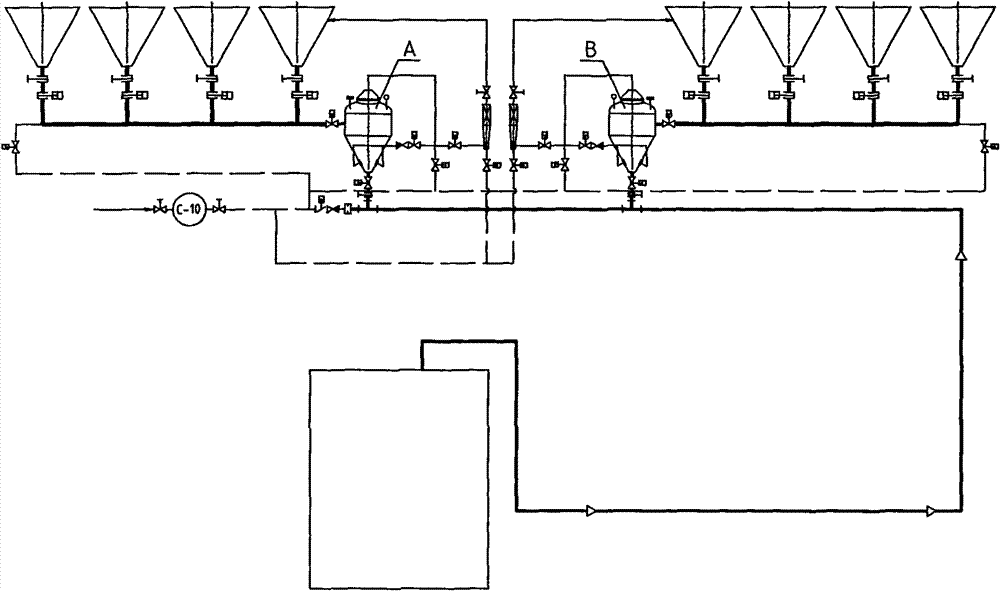

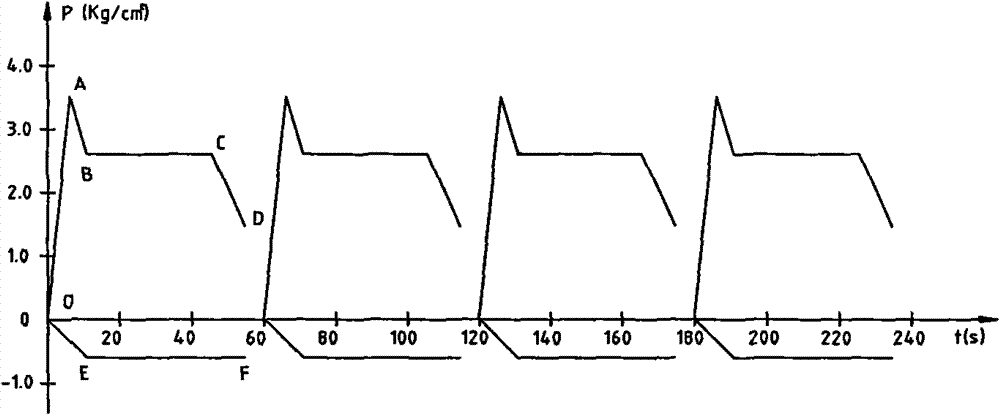

[0028] The working process of the present invention is: open the conveying compressed air system, when the pressure reaches the preset value, open the pneumatic air intake valve of the ash conveying pipeline, convey compressed air to purge the ash conveying pipeline for 3-5 minutes.

[0029] (1) Multi-function pump negative pressure ash loading: open the pneumatic air intake valve of the warehouse pump air extractor, when the negative pressure in the warehouse pump reaches the preset value, the warehouse pump pressure transmitter outputs a signal to open the warehouse pump pneumatic air inlet valve. The material valve and the pneumatic ash unloading valve under the ash hopper of the flue gas dust collector open the positive pressure air supply valve at the end of the negative pressure ash conveying pipeline, and the dry ash in the ash hopper is sucked into the down-drawing silo pump, and the down-drawing silo pump The material level gauge outputs the signal, and the multi-funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com