Aluminium-based compound capable of having hydrolysis reaction under neutral and normal temperature conditions to produce hydrogen and preparation method thereof

An aluminum-based composite, hydrolysis hydrogen production technology, applied in hydrogen production and other directions, to achieve the effect of improving hydrogen yield, accelerating aluminum hydrolysis reaction rate, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

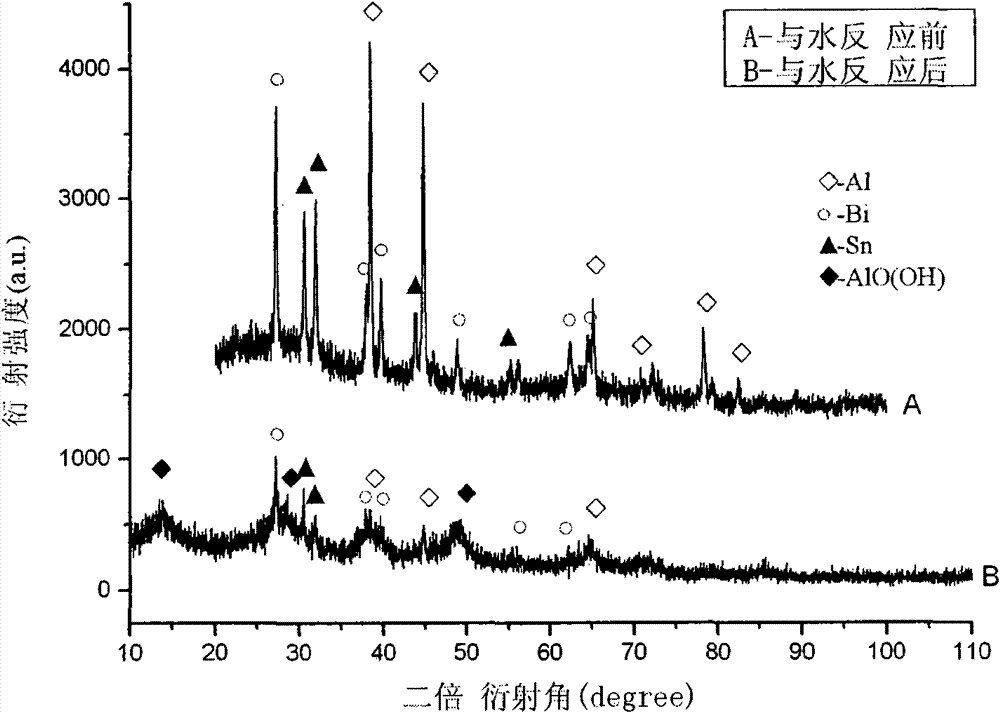

[0013] Bismuth powder and tin powder are evenly mixed in a mass ratio of 1:1, and pressed into a cylindrical shape in a steel mold. Put the cylindrical bismuth powder-tin powder mixture into a vacuum electric arc furnace for smelting four times, and then spin it on a vacuum strip machine to obtain bismuth-tin amorphous or nanocrystalline alloy thin strips. 2~3um metal pure aluminum powder and bismuth-tin amorphous or nanocrystalline alloy thin strips are put into a stainless steel ball mill tank at a mass ratio of 100:20, and the aluminum matrix composite is obtained after ball milling under the protection of a high-purity Ar atmosphere for 16 hours. thing. Add the aluminum-based composite to pure water at 30°C, and continue to react with water. The reaction is completed within 10 minutes, and the actual hydrogen production rate of the aluminum powder is as high as 93.4%. The product is aluminum oxyhydroxide that can be recycled, and the aluminum-based composite The XRD patte...

Embodiment 2

[0015] Bismuth powder and indium powder are uniformly mixed at a mass ratio of 3:7, and pressed into a cylindrical shape in a steel mold. The cylindrical bismuth powder-indium powder mixture is smelted in a vacuum electric arc furnace for 4 times, and then stripped on a vacuum strip machine to obtain bismuth-indium amorphous or nanocrystalline alloy thin strips. 2~3um metal pure aluminum powder and bismuth-indium amorphous or nanocrystalline alloy thin strips are put into a stainless steel ball mill tank at a mass ratio of 100:10, and the aluminum matrix composite is obtained after ball milling under the protection of a high-purity Ar atmosphere for 24 hours. things. Add the aluminum-based composite to pure water at 20°C, and continue to react with the water. The reaction is completed within 20 minutes. The actual hydrogen production rate of the aluminum powder is about 78%, and the product is aluminum oxyhydroxide that can be recycled.

Embodiment 3

[0017] Bismuth powder, tin powder and zinc powder are uniformly mixed in a mass ratio of 5:4:1, and pressed into a cylindrical shape in a steel mold. The cylindrical bismuth-tin-zinc powder mixture is smelted in a vacuum electric arc furnace for 4 times, and then stripped on a vacuum strip machine to obtain bismuth-tin-zinc amorphous or nanocrystalline alloy thin strips. 4~6um metal pure aluminum powder and bismuth-tin-zinc amorphous or nanocrystalline alloy thin strips are put into a stainless steel ball mill tank at a mass ratio of 100:5, and aluminum is obtained after ball milling under the protection of a high-purity Ar atmosphere for 16 hours. base complex. Add the aluminum-based composite to pure water at 20°C, and continue to react with the water. The reaction is completed within 15 minutes. The actual hydrogen production rate of the aluminum powder is about 83%, and the product is aluminum oxyhydroxide that can be recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com