Method for preparing hydrogen chloride and ammonia by utilizing ammonium chloride

A technology of ammonium chloride and hydrogen chloride, applied in the direction of chlorine/hydrogen chloride, preparation with chloride, preparation/separation of ammonia, etc., can solve problems such as side reactions, low purity, low reaction rate of acid release, etc., and achieve increased reaction speed , high initial purity, and the effect of reducing the amount of sublimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

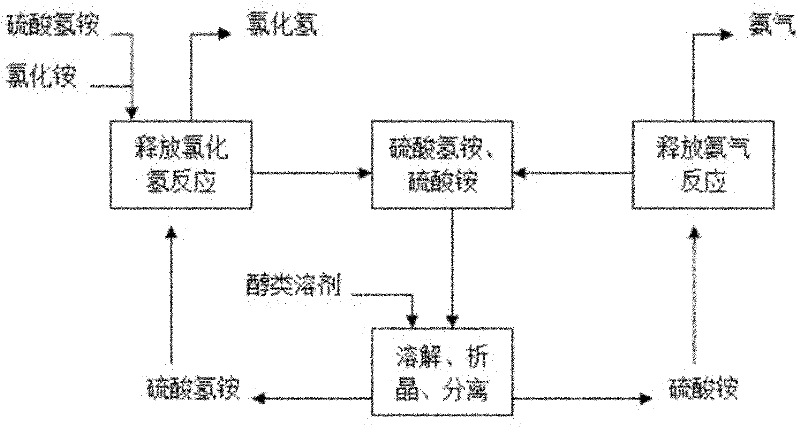

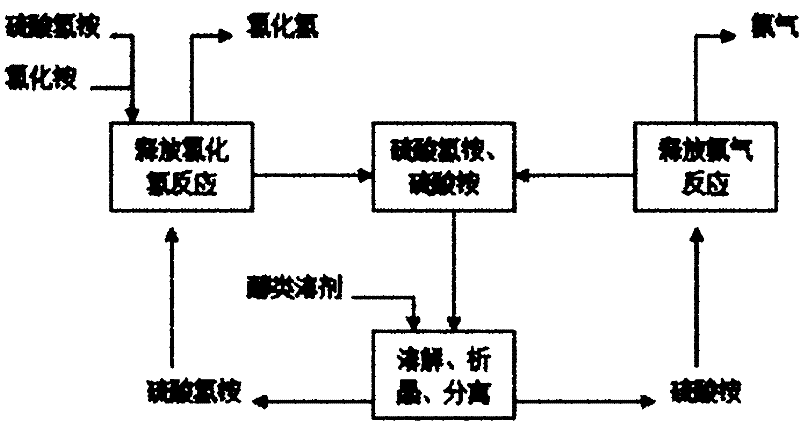

[0034] Such as figure 1 Shown, a kind of ammonium chloride produces the method for hydrogen chloride and ammonia, comprises the following steps:

[0035] 1. Acid release reaction process

[0036] During the acid release reaction, first add the intermediate separation inorganic acidic solvent ammonium bisulfate to the reaction kettle, after heating up to 180°C, add the dried and sieved solid ammonium chloride with a particle size of 40 mesh, hydrogen sulfate The molar ratio of ammonium to ammonium chloride is 1:1. At this time, a large amount of hydrogen chloride gas is produced. After 2 hours of constant temperature reaction, the conversion rate of ammonium chloride reaches 90.5%. The hydrogen chloride gas produced has a purity of 91.8% without treatment and can be used after treatment. In the production or preparation of high-purity hydrochloric acid in PVC, the remaining ammonium bisulfate and ammonium sulfate are crystallized and separated;

[0037] 2. Intermediate separa...

Embodiment 2

[0042] A method for ammonium chloride to produce hydrogen chloride and ammonia, comprising the following steps:

[0043] 1. Acid release reaction process

[0044]During the acid release reaction, first add the intermediate separation inorganic acidic solvent ammonium bisulfate to the reaction kettle, after heating up to 250°C, add the dried and sieved solid ammonium chloride with a particle size of 100 mesh, hydrogen sulfate The molar ratio of ammonium to ammonium chloride is 5:1. At this time, a large amount of hydrogen chloride gas is produced. After 2 hours of constant temperature reaction, the conversion rate of ammonium chloride reaches 91.5%. The hydrogen chloride gas produced has a purity of 93.2% without treatment and can be used after treatment In the production or preparation of high-purity hydrochloric acid in PVC, the remaining ammonium bisulfate and ammonium sulfate are crystallized and separated;

[0045] 2. Intermediate separation process

[0046] The molten m...

Embodiment 3

[0050] A method for ammonium chloride to produce hydrogen chloride and ammonia, comprising the following steps:

[0051] 1. Acid release reaction process

[0052] During the acid release reaction, first add the intermediate separation inorganic acidic solvent ammonium bisulfate to the reaction kettle, after heating up to 220°C, add the dried and sieved solid ammonium chloride with a particle size of 60 mesh, hydrogen sulfate The molar ratio of ammonium to ammonium chloride is 3:1. At this time, a large amount of hydrogen chloride gas is produced. After 2 hours of constant temperature reaction, the conversion rate of ammonium chloride reaches 90.8%. The hydrogen chloride gas produced has a purity of 92.6% without treatment and can be used after treatment In the production or preparation of high-purity hydrochloric acid in PVC, the remaining ammonium bisulfate and ammonium sulfate are crystallized and separated;

[0053] 2. Intermediate separation process

[0054] The molten m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com