Method for purifying sewage in vertical-flow artificial wetland

A technology of artificial wetland and vertical underflow, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of long pipelines, large construction investment, blockage, etc., and reduce construction investment , Increase water flow time, improve the effect of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The design processing capacity is 1000 tons / day, and the total area of constructed wetland is 1600m 2 , divided into two grids, each grid is 800m 2 , the two grids are connected in parallel and respectively enter the water. The aspect ratio of the constructed wetland foundation pit is 1: 1, and the bottom slope of the excavated foundation pit is 0.8%, which is inclined towards the outlet of the water collection pipe. The surface slope cannot exceed 0.3m, and the depth of the foundation pit is 2.5m. The raw sewage enters the coagulation sedimentation tank through the grid for sedimentation, and then enters the aeration tank to be oxygenated and oxidized, and then the pretreated COD is reduced to below 100mg / L, and the inorganic suspended solids (SS) are reduced to below 20mg / L. The supernatant is introduced into the constructed wetland for treatment.

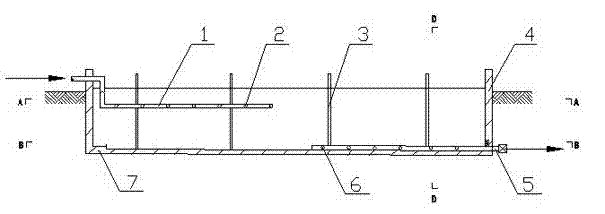

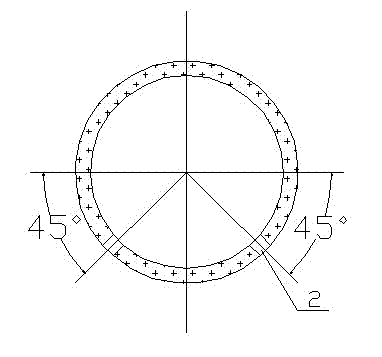

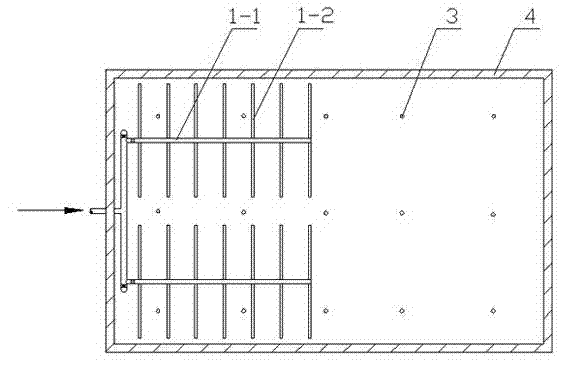

[0046] as the picture shows, The constructed wetland is composed of a foundation pit 7, a cofferdam 4, a water dis...

Embodiment 2

[0063] The design processing capacity is 2,000 tons / day, and the total area of constructed wetland is 3,000m 2 , divided into three grids, each grid is 1000m 2 , the three grids are connected in parallel and enter water separately. The aspect ratio of the constructed wetland foundation pit is 1:3, the bottom slope of the excavated foundation pit is 0.5%, and it is inclined towards the outlet of the water collection pipe, the surface slope cannot exceed 0.3m, and the depth of the foundation pit is 1.5m. The raw sewage enters the coagulation sedimentation tank through the grid for sedimentation, and then enters the aeration tank to be oxygenated and oxidized, and then the pretreated COD is reduced to below 100mg / L, and the inorganic suspended solids (SS) are reduced to below 20mg / L. The supernatant is introduced into the constructed wetland for treatment.

[0064] The constructed wetland is composed of a foundation pit, cofferdam, water distribution pipe network, water colle...

Embodiment 3

[0081] The design processing capacity is 2,000 tons / day, and the total area of constructed wetland is 3,000m 2 , divided into three grids, each grid is 1000m 2 , the three grids are connected in parallel and enter water separately. The aspect ratio of the constructed wetland foundation pit is 1:5, the slope of the bottom of the excavated foundation pit is 0.8%, inclined towards the outlet of the water collection pipe, and the depth of the foundation pit is 2.0m. The raw sewage enters the coagulation sedimentation tank through the grid for sedimentation, and then enters the aeration tank to be oxygenated and oxidized, and then the pretreated COD is reduced to below 100mg / L, and the inorganic suspended solids (SS) are reduced to below 20mg / L. The supernatant is introduced into the constructed wetland for treatment.

[0082] The constructed wetland is composed of a foundation pit, cofferdam, water distribution pipe network, water collection pipe network, a filler layer with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com