Formula for low-temperature wear-resisting plastic coating material

A spreader and formulation technology, which is applied in the field of low-temperature wear-resistant plastic spreader formulations, can solve the problems of wear-resistant ceramic coatings such as low strength, ceramic coating shedding, and poor wear resistance, so as to increase wear resistance and life span , good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

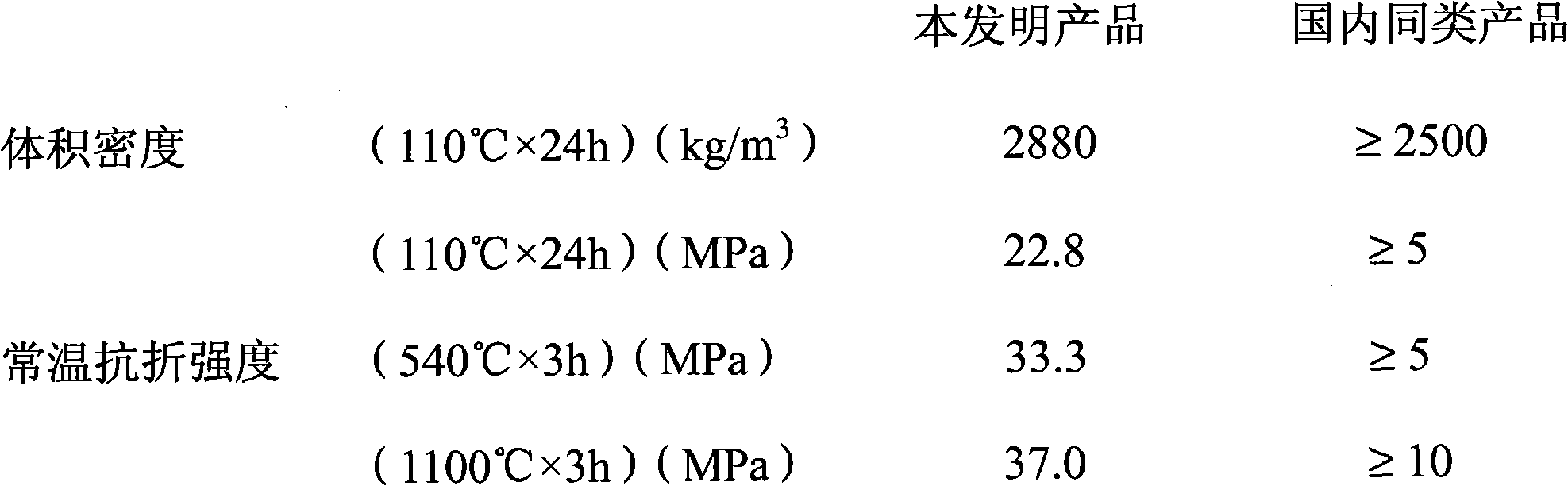

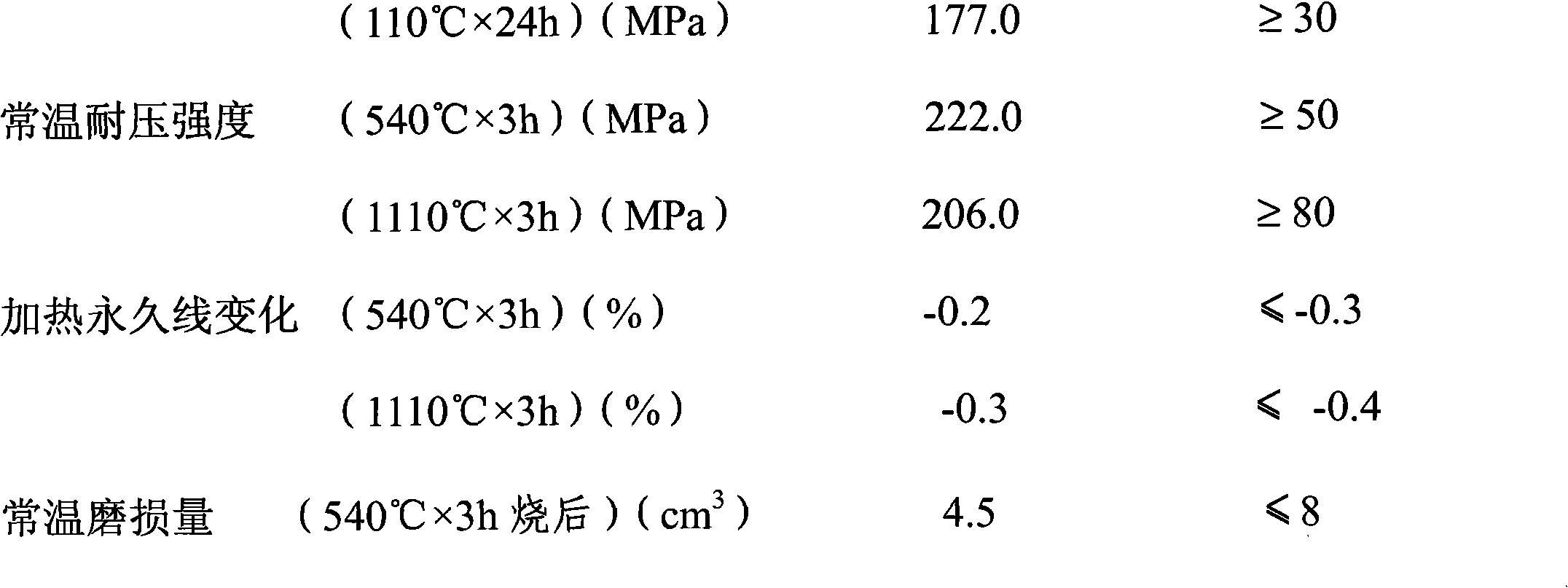

Examples

Embodiment 1

[0020] Example 1, a low-temperature wear-resistant plastic smear formula, the weight percentage of each component in the formula is 80% of high-bauxite clinker, 10% of silicon carbide, and 10% of aluminate cement.

Embodiment 2

[0021] Example 2, the weight percent of each component in the formula is 65% of high alumina bauxite clinker, 10% of silicon carbide, 10% of aluminate cement, 5% of silicon micropowder, 7% of alumina micropowder, ρ-Al 2 o 3 Micronized 3%.

Embodiment 3

[0022] Example 3, the weight percent of each component in the formula is 85% of high alumina bauxite clinker, 5% of silicon carbide, 5% of aluminate cement, 1% of alumina micropowder, ρ-Al 2 o 3 2%, compound additive 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com