Sewage zero-emission metal strip surface cleaning device and method

A metal strip and surface cleaning technology, which is applied to a metal strip surface cleaning device and its cleaning field, can solve the problems of high processing costs, the liquid cannot be recovered, and only a small amount can be recovered, so as to achieve less space occupation and increase electrolytic cleaning. Effect, good effect of brushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

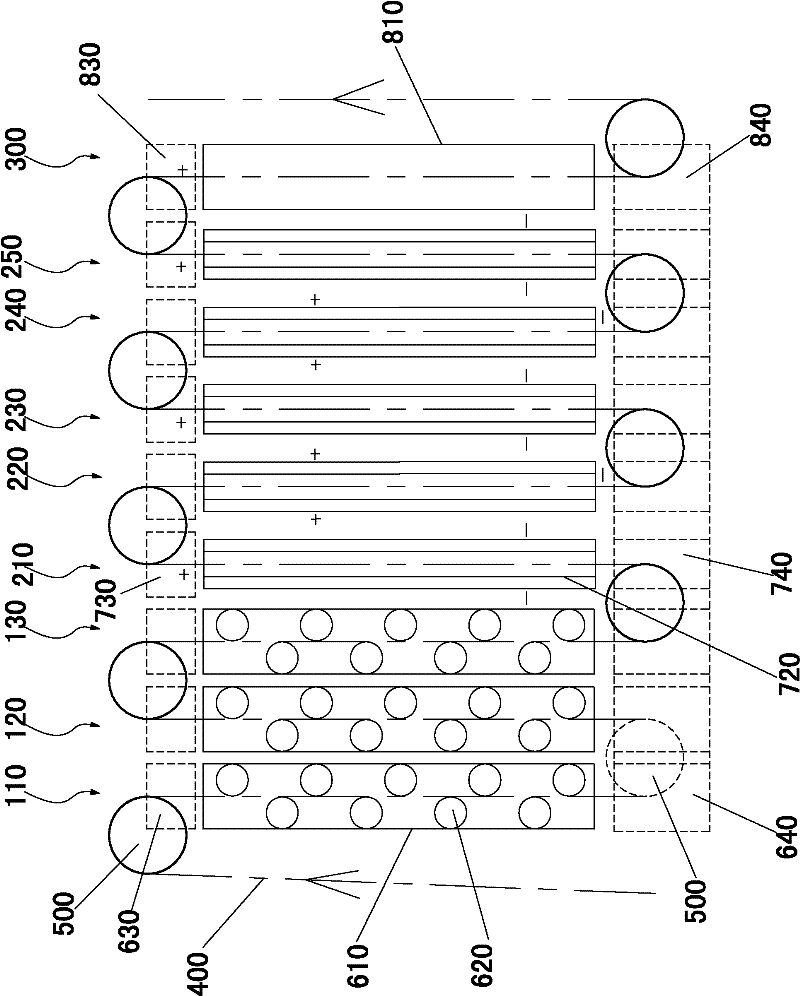

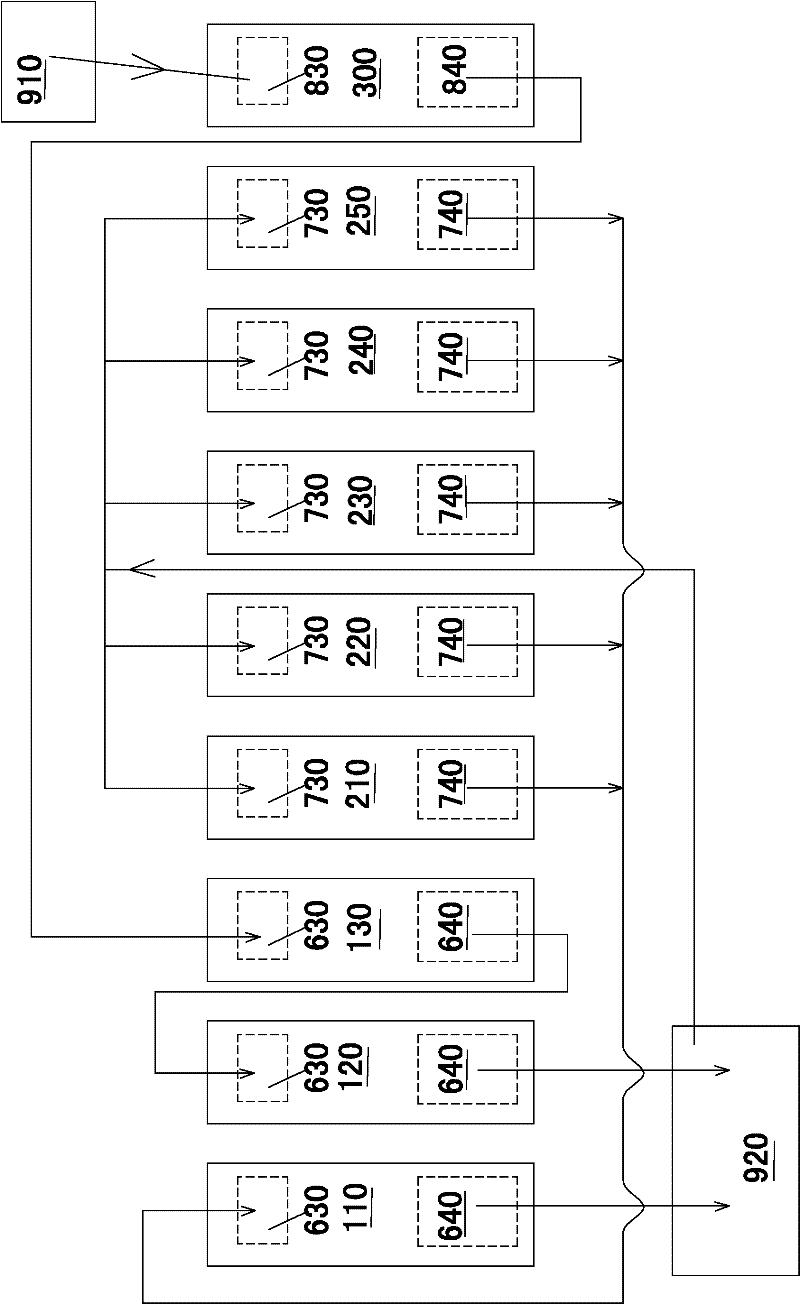

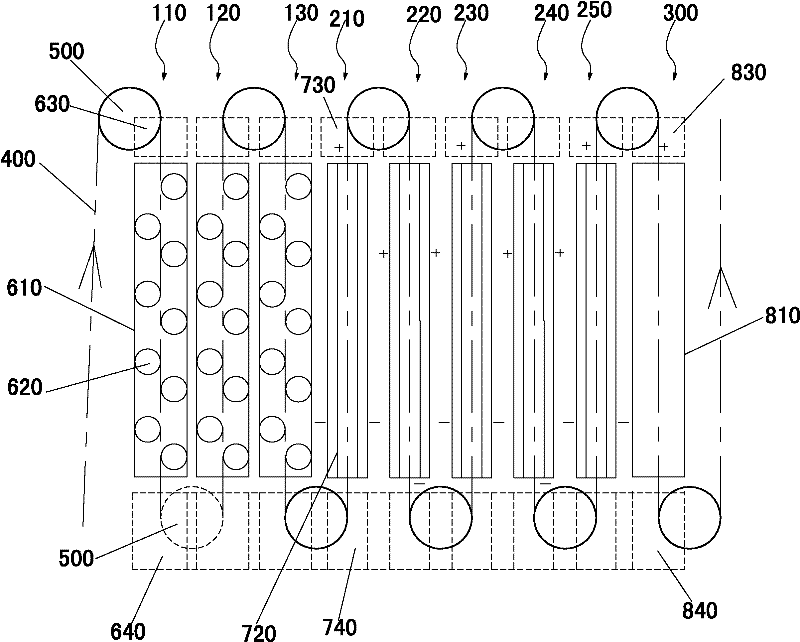

[0071] Please check figure 1 and figure 2 A metal strip surface cleaning device with zero discharge of sewage, which includes three brushing units 110, 120, 130, five electrolytic cleaning units 210, 220, 230, 240, 250, a spraying unit 300 and a water circulation system. The metal strip passes through the brush cleaning units 110 , 120 , 130 , the electrolytic cleaning units 210 , 220 , 230 , 240 , 250 and the spray cleaning unit 300 in sequence.

[0072] The metal strip 400 is fed by a plurality of rotating rollers 500 arranged in a staggered up and down manner, and forms a wave-like feeding. Wherein: the brushing units 110, 120, 130, the electrolytic cleaning units 210, 220, 230, 240, 250 and the spraying unit 300 are successively arranged on one side of the adjacent upper and lower turning rollers 500, and the arrangement by this method can reduce the occupancy space.

[0073] The brushing units 110 , 120 , 130 all include a scrubbing shell 610 , a scrubbing mechanism 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com