Process for manufacturing rotating shuttle inner shuttle bottom supporting structure

A manufacturing process and bottom support technology, which is applied in the manufacturing process field of the bottom support structure of the inner hook of the rotary hook, can solve problems such as the inability to meet the manufacturing needs of the rotary hook, and achieve the effects of improving production efficiency and production quality, high hardness, and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

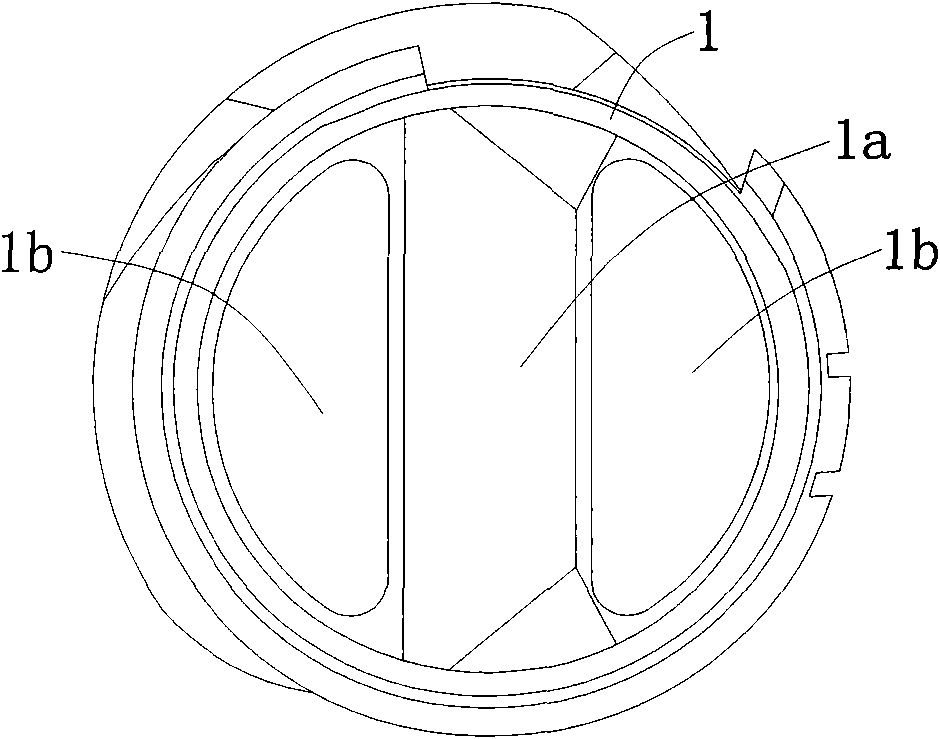

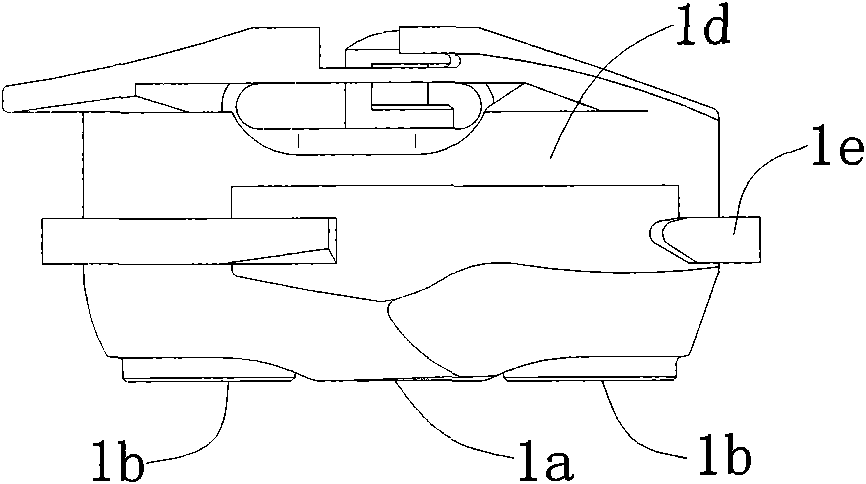

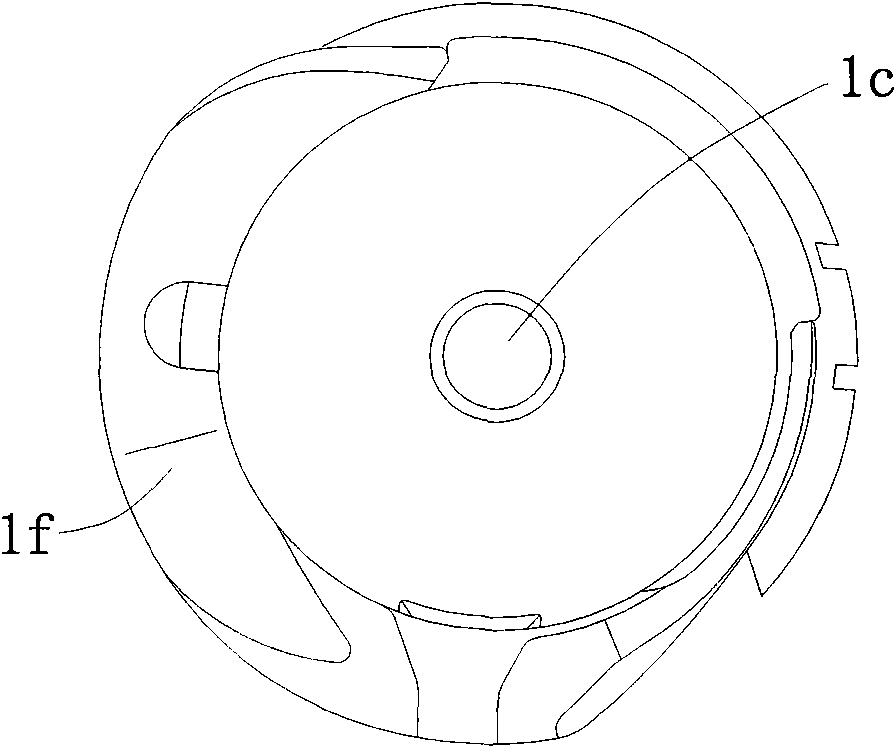

[0027] Figure 1a to Figure 3 Shown is the structural representation of the present invention.

[0028] The reference signs therein are: rotary hook inner hook blank 1, strip plate 1a, support plate 1b, central axis 1c, cylindrical side wall 1d, guide rail 1e, platform 1f, hollow hole 2.

[0029] Such as Figures 2a to 2c As shown, the rotary hook inner shuttle of the present invention includes a cylindrical side wall 1d, an open end located at the upper end of the cylindrical side wall 1d, and a bottom located at the lower end of the cylindrical side wall 1d. A strip plate 1a is formed on the bottom of the hook in the rotary hook, and a central axis 1c is formed on the strip plate 1a. A guide rail 1e is formed on the outer wall of the cylindrical side wall 1d in the circumferential direction.

[0030] Such as image 3 As shown, the manufa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com