Plastic building template

A technology for building formwork and plastics, which is applied in construction, building structure, formwork/formwork components, etc., to achieve the effect of improving strength, light weight and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

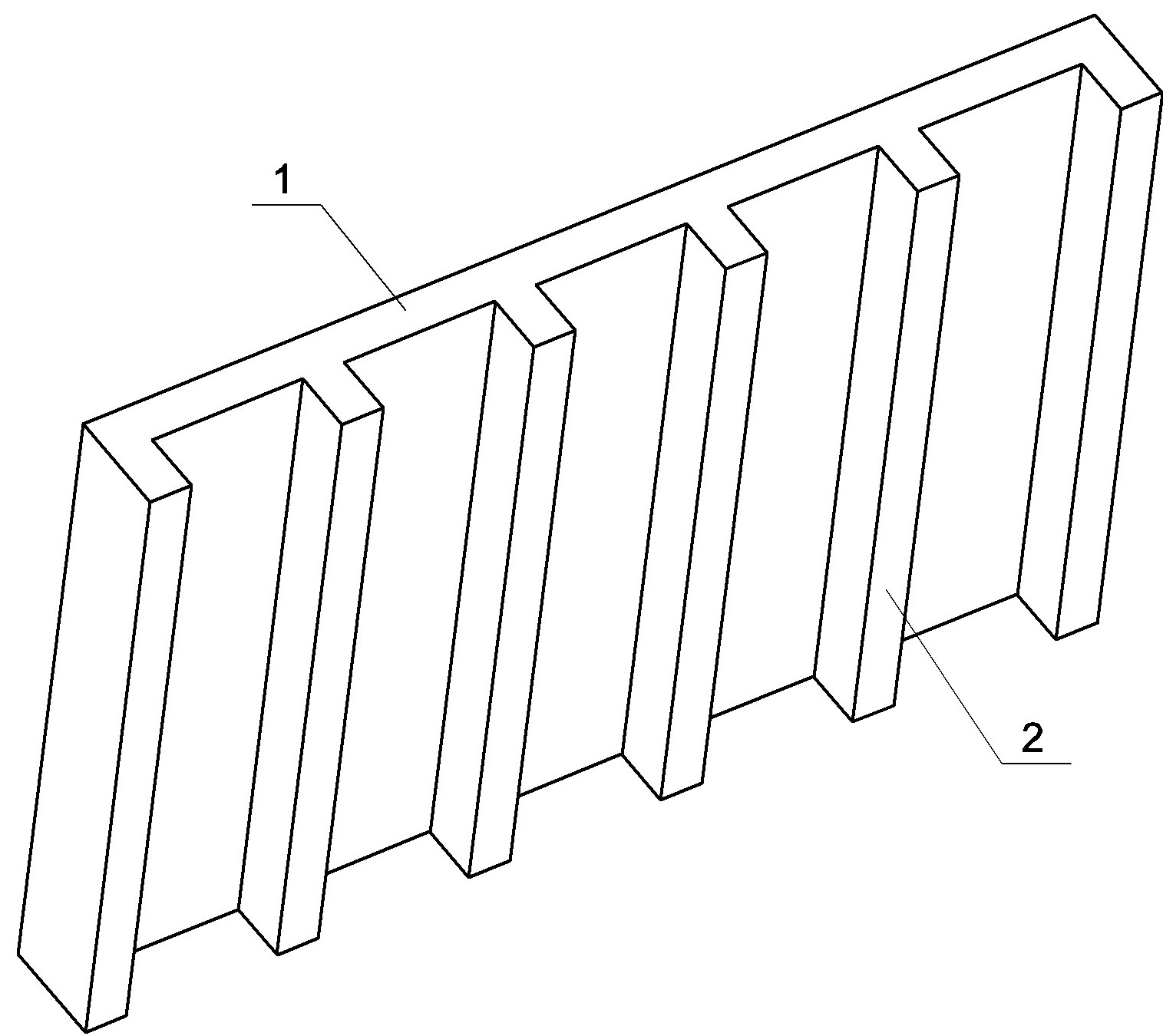

Embodiment 1

[0030] Example 1: see figure 1 , a plastic building formwork, including a plane main plate 1, a rectangular cross-section reinforcing rib 2 located on one side of the plane plate, wherein the plane main plate and the reinforcing ribs are solid plates formed by PVC foam material at one time. The template of the invention is prepared from S700 type PVC resin, adding AC foaming agent and regulator. The process uses the Seluka foaming method, adopts a special mold, and increases the pressure on the surface layer to cool the skin during the time of exiting the mold. Make the skin crust, the thickness of the crust is about 1mm, and the hardness meets the requirements of the template. The core reduces the pressure and causes it to foam. The overall weight of the formwork is reduced, and the formwork is easy to use in construction. The Vicat softening temperature of the solid board is 97°C, the elastic modulus is 3000, and the bending resistance is 60MPa.

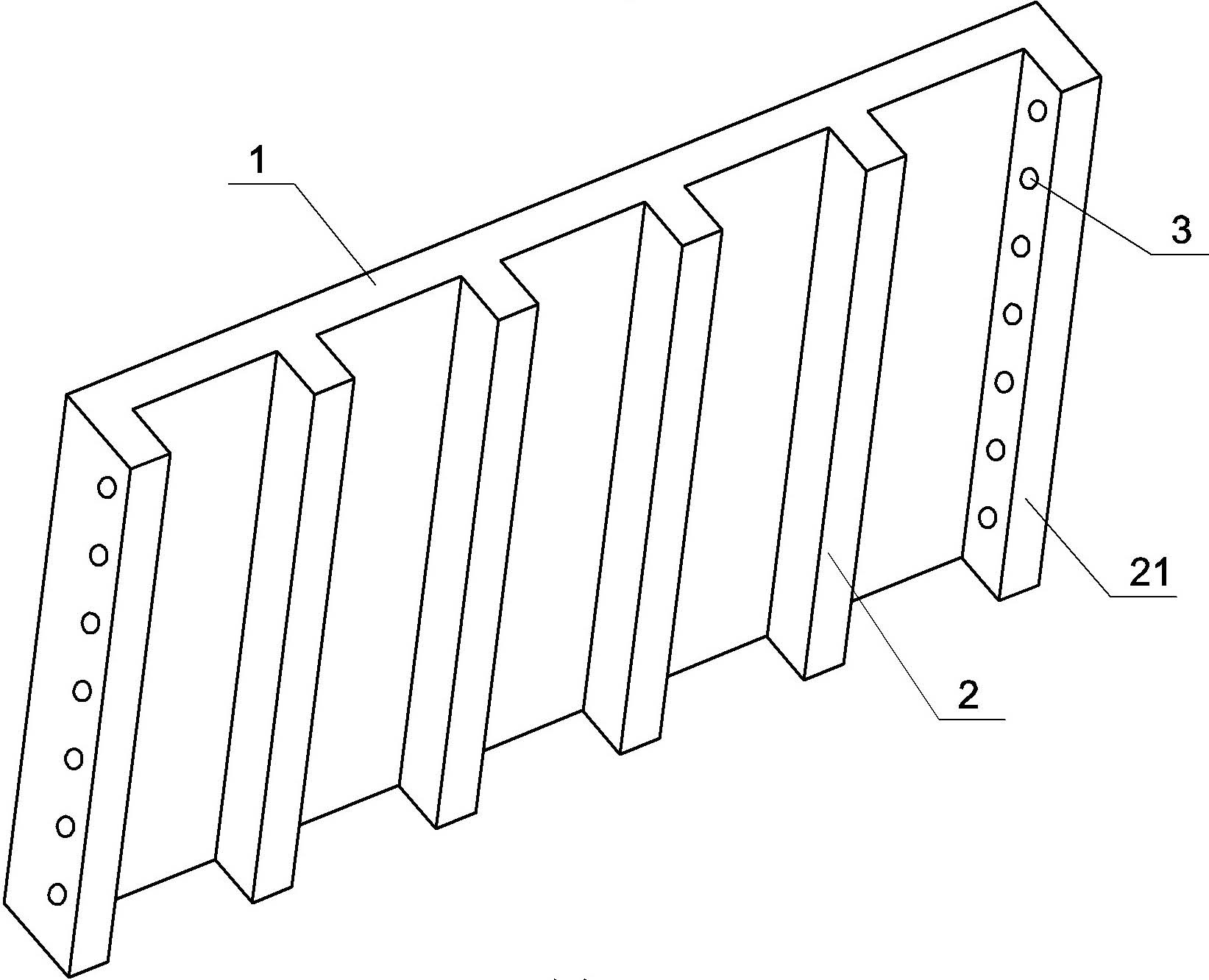

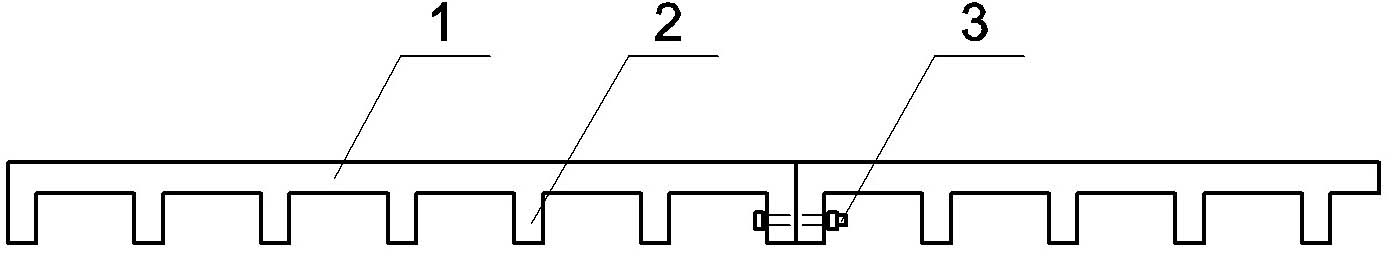

Embodiment 2

[0031] Example 2: see figure 2 , image 3 , Figure 4 , a plastic building formwork, basically the same as the first embodiment, comprising a flat main body plate 1, a rectangular cross-section reinforcing rib 2 located on one side of the flat plate, wherein the flat main body plate and the reinforcing rib are formed by PVC foam material at one time solid board. Wherein, fixed through holes or threaded holes 31 are distributed on the outermost reinforcing ribs on both sides. image 3 It shows that the two left and right adjacent formwork are fixed by steel nails in the through holes on the outermost reinforcing rib, or by threaded fixing in the threaded holes. Figure 4 The back surfaces of two upper and lower adjacent templates are shown to be fixed together by connecting plates, wherein the connecting plates can be fixed directly on the back side of the plane main board or on the back side reinforcing rib of the plane main board. in addition, image 3 A representation ...

Embodiment 3

[0032] Example 3: see Figure 5 , the content is basically the same as that of the first or second embodiment, and the similarities will not be repeated. The difference is that the cross-section of the reinforcing rib on the side of the template is an isosceles trapezoid or a right-angled trapezoid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com