Composite phase-transition heat exchanging device for warming clean gas fume and recovering exhaust heat after wet desulphurization

A composite phase inversion heat and wet desulfurization technology, which is applied in the field of composite phase inversion heat devices, can solve the problems of no real success, waste of water resources, large steam consumption, etc., so as to reduce the amount of cooling water and improve thermal efficiency. , the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

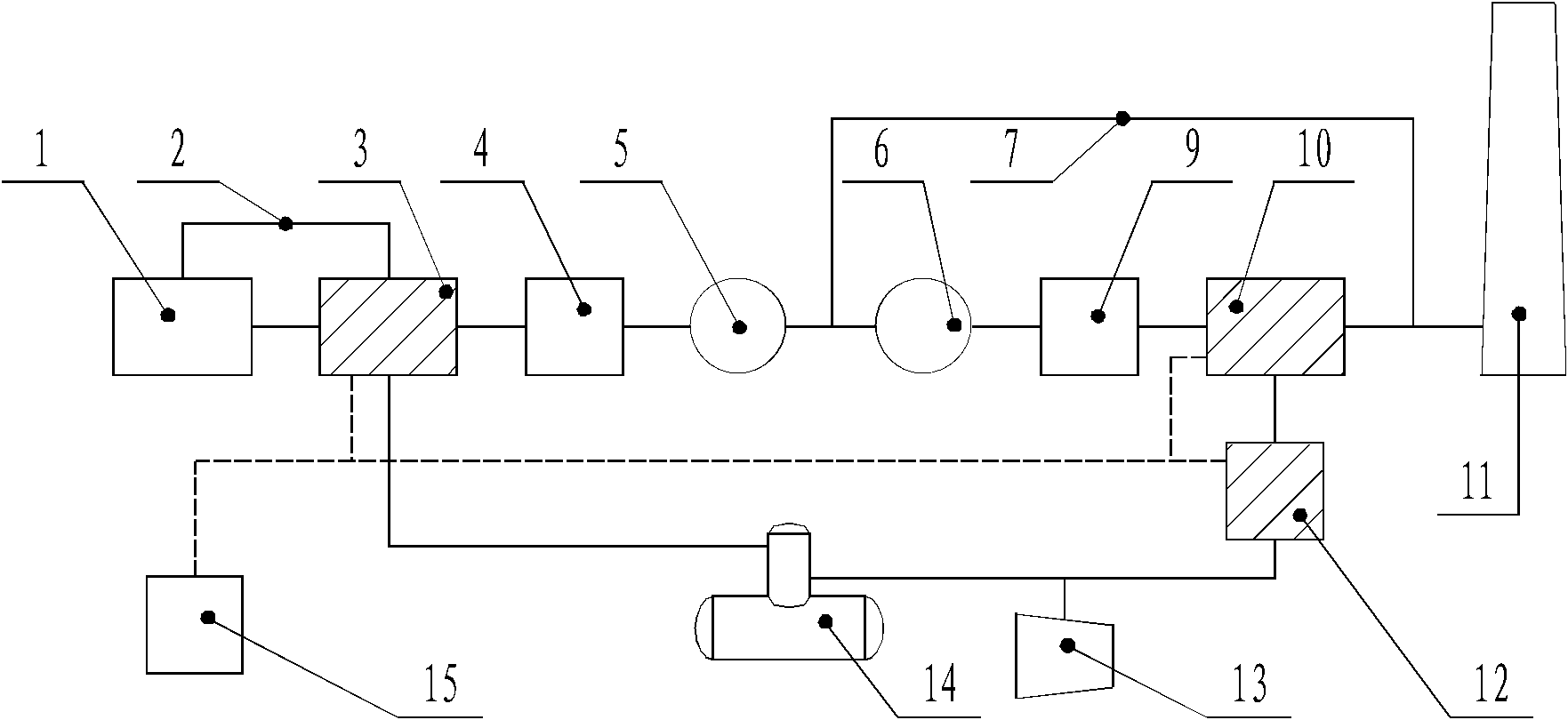

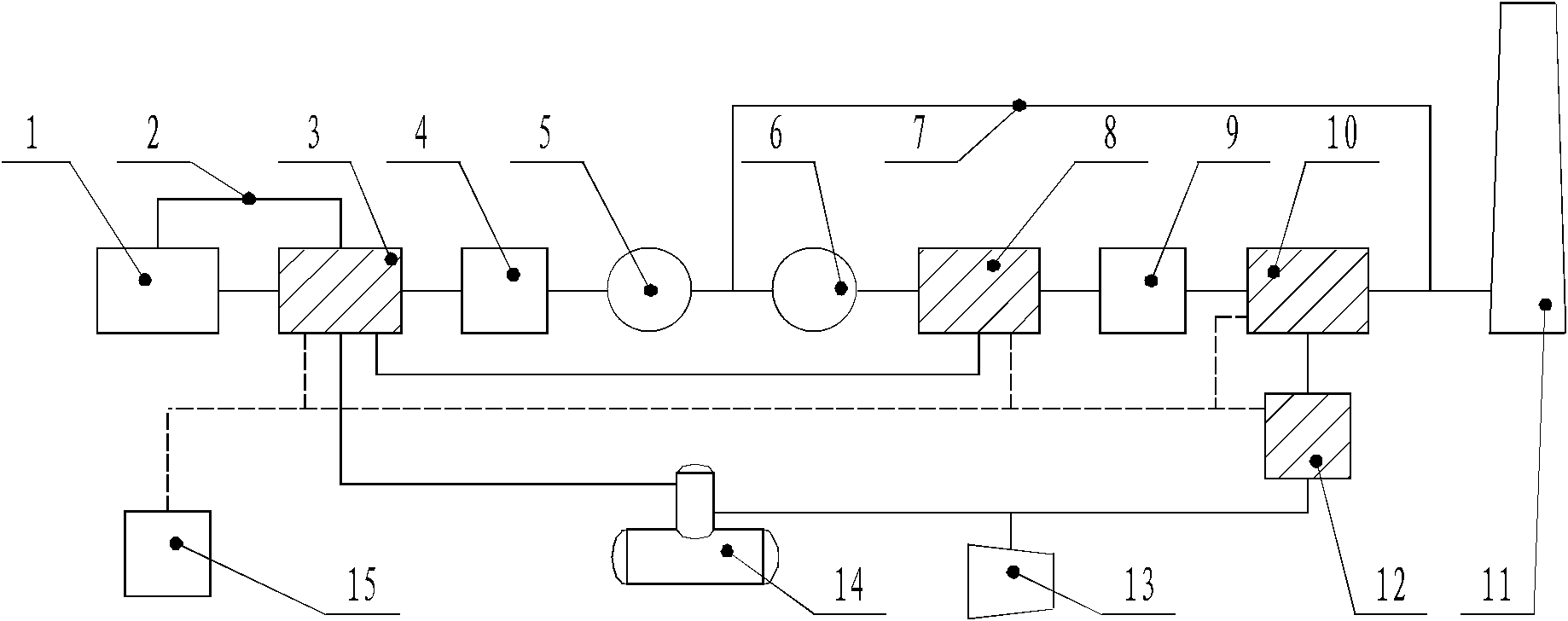

[0035] This embodiment includes: I-level phase-change heat exchanger 3, electric control cabinet 15, III-level phase-change heat exchanger 10, and I-level phase-change heat exchanger 3 are connected to III-level phase-change heat exchanger 10 successively through pipelines, constant temperature The humidifier 12 and the first-stage phase-change heat exchanger 3 are connected to the electric control cabinet 15 through wiring, and the constant-temperature humidifier 12 is connected to the first-stage phase-change heat exchanger 3 through pipelines.

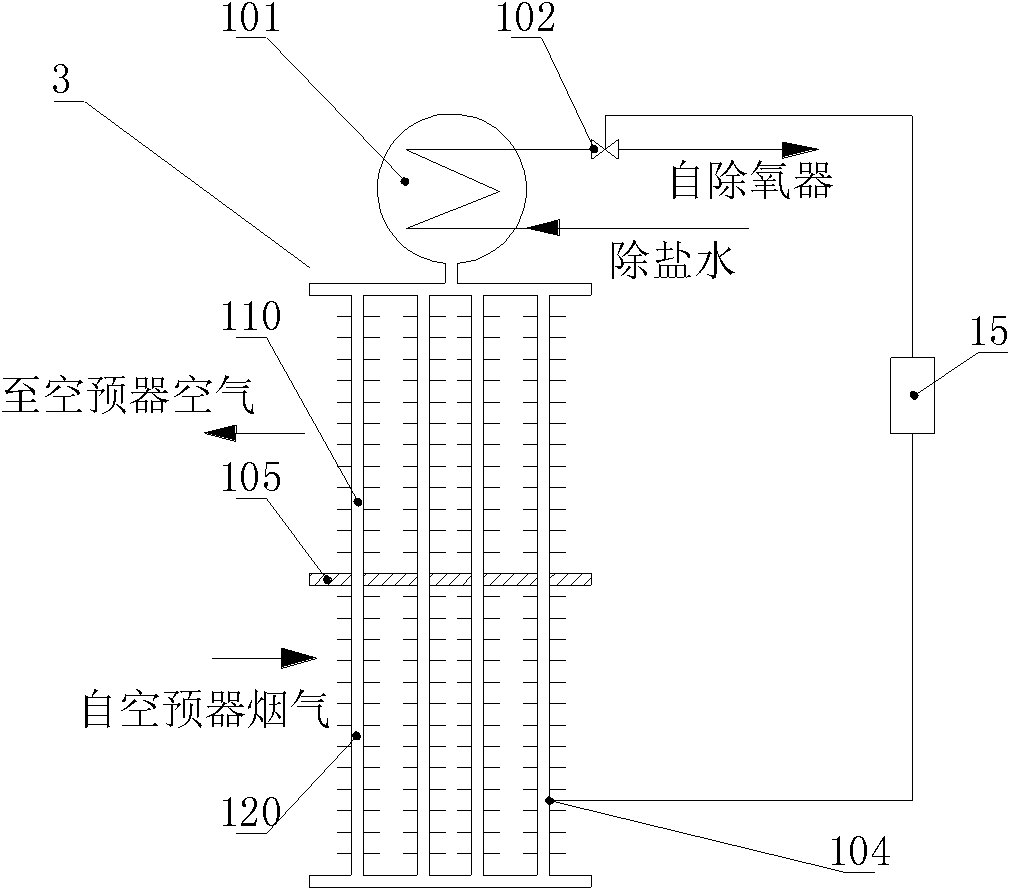

[0036] The first-stage phase-change heat exchanger 3 described in this embodiment includes: a steam drum 101, a desalinated water regulating valve 102, a temperature measuring instrument 104, and a phase change lower section 120, which is arranged after the air preheater 1 of the boiler system In the flue of the flue, the phase change lower section 120 of the I-stage phase-change heat exchanger 3 is sequentially connected in series t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com