Quadrupole variable-frequency motor rotor punching sheet

A technology of rotor punching and frequency conversion motor, which is applied to the magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of motor noise exceeding the standard, achieve the effect of meeting design requirements and reducing electromagnetic noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiments in the drawings:

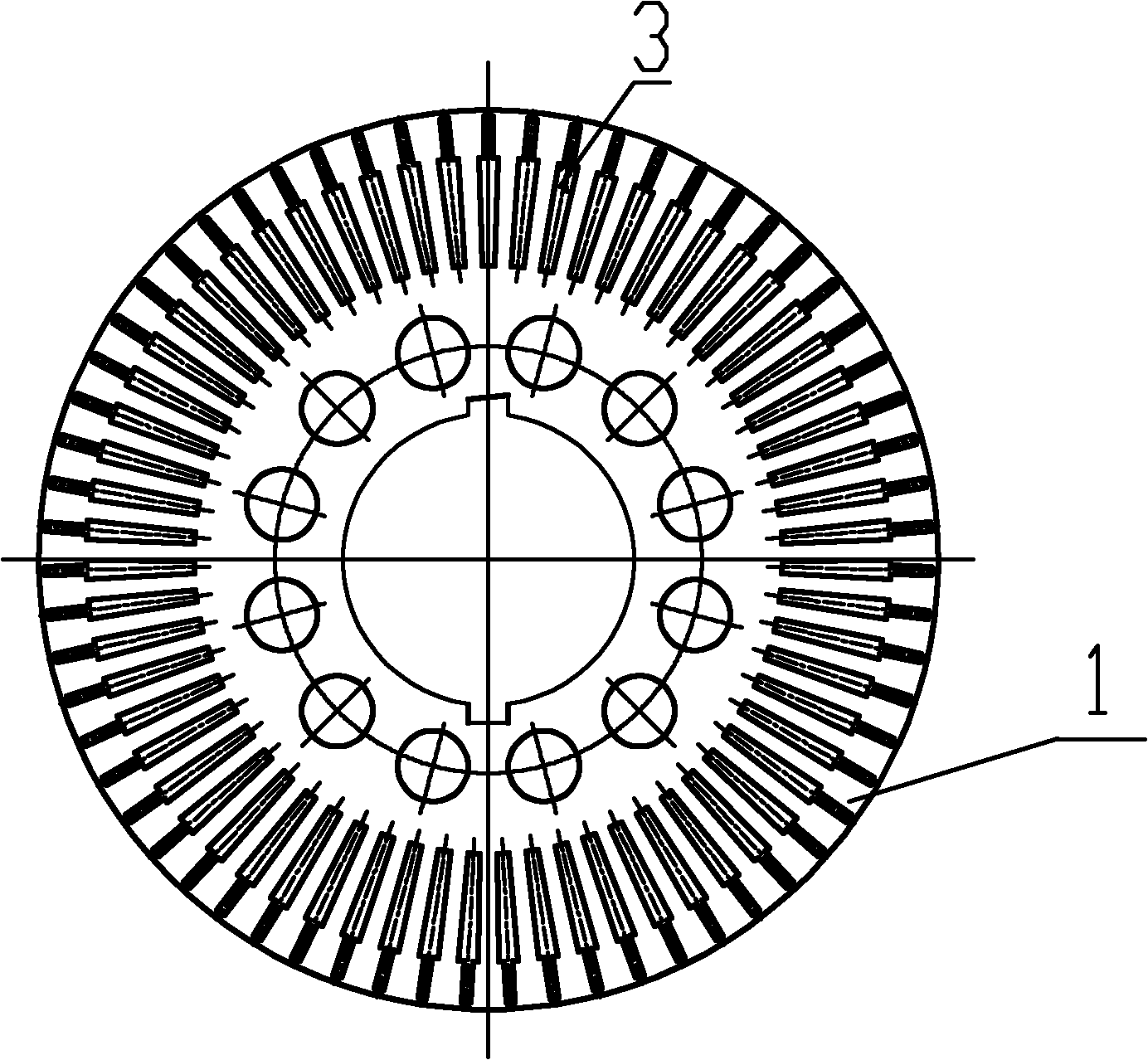

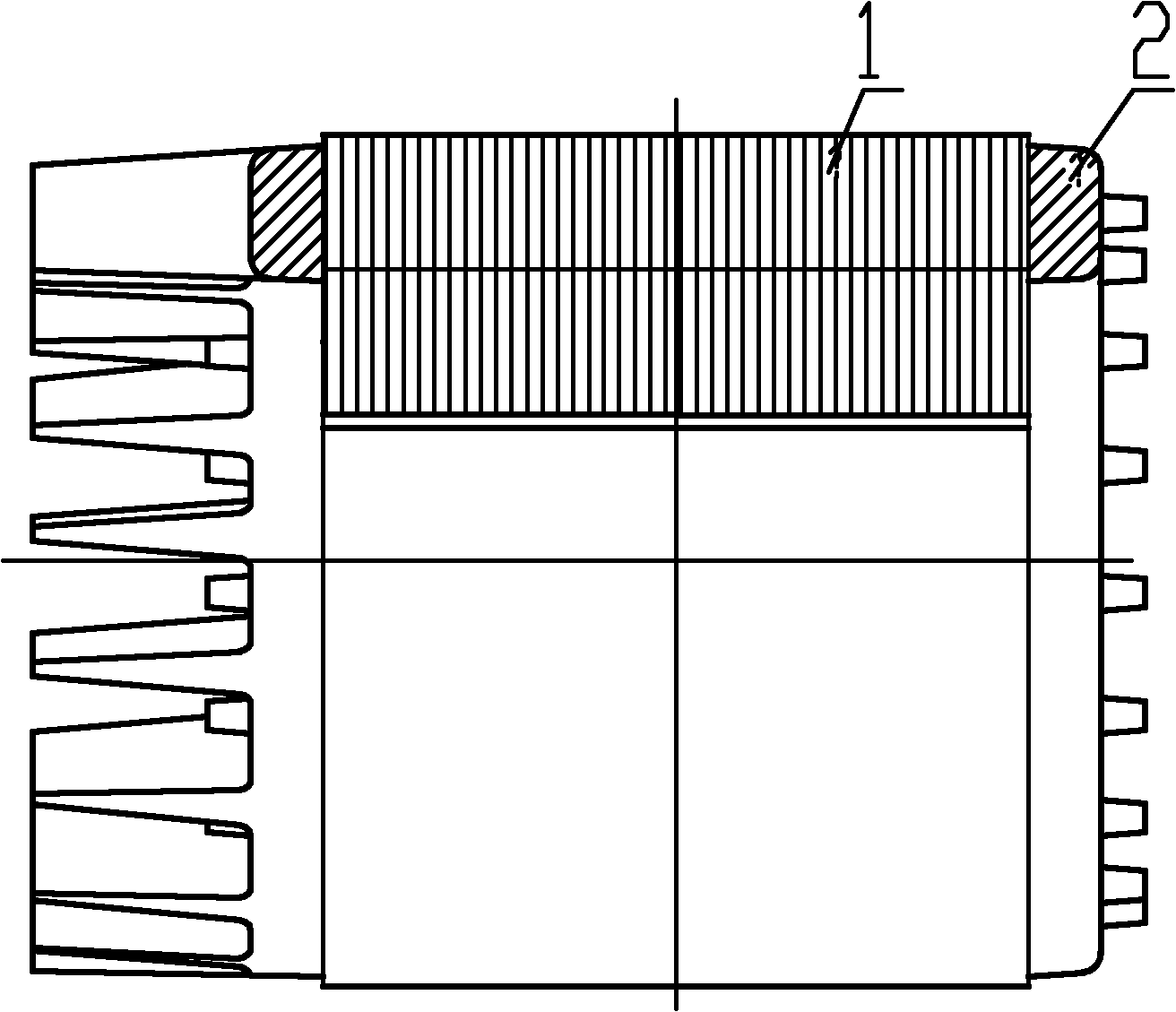

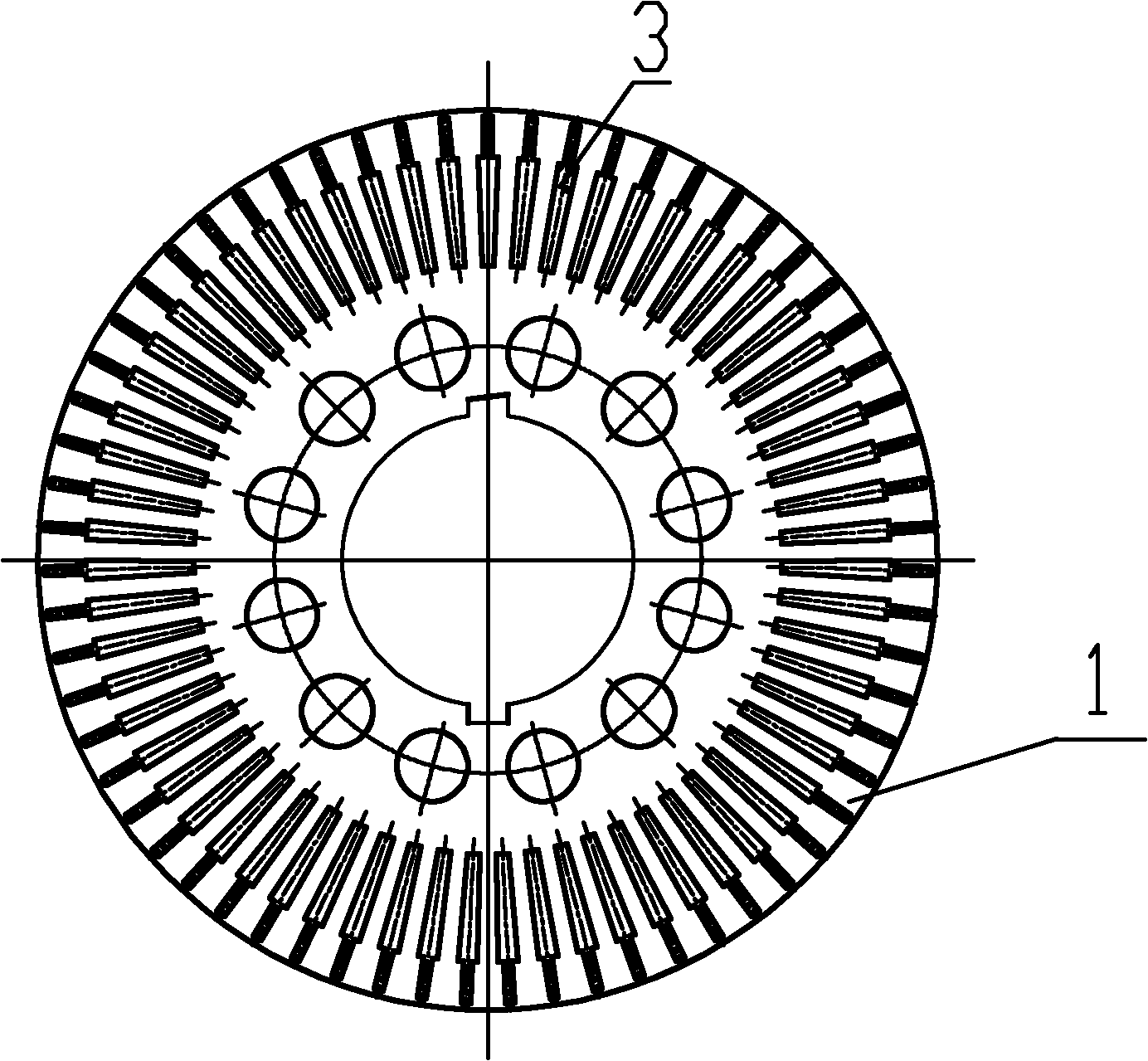

[0012] The present invention only needs to change the punching die of the rotor punching sheet, use silicon steel sheet to punch out the rotor punching sheet body 1 on the punching machine, and 63 rotor punching grooves 3 are provided on the rotor punching sheet body 1, and then the special rotor die casting machine A certain number of rotor punching pieces 1 and aluminum 2 are die-casted into one body to form a cast aluminum rotor. The solution of the invention does not change the original assembly method of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com