Apparatus and method for automatically and remotely measuring the internal gap of a reactor

A technology for nuclear reactors and gaps, which is applied to measurement devices, reactors, nuclear reactor monitoring, etc., can solve the problems of increased measurement and construction periods, long time consumption, and difficulty in obtaining measurement values, so as to improve work efficiency and shorten construction periods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

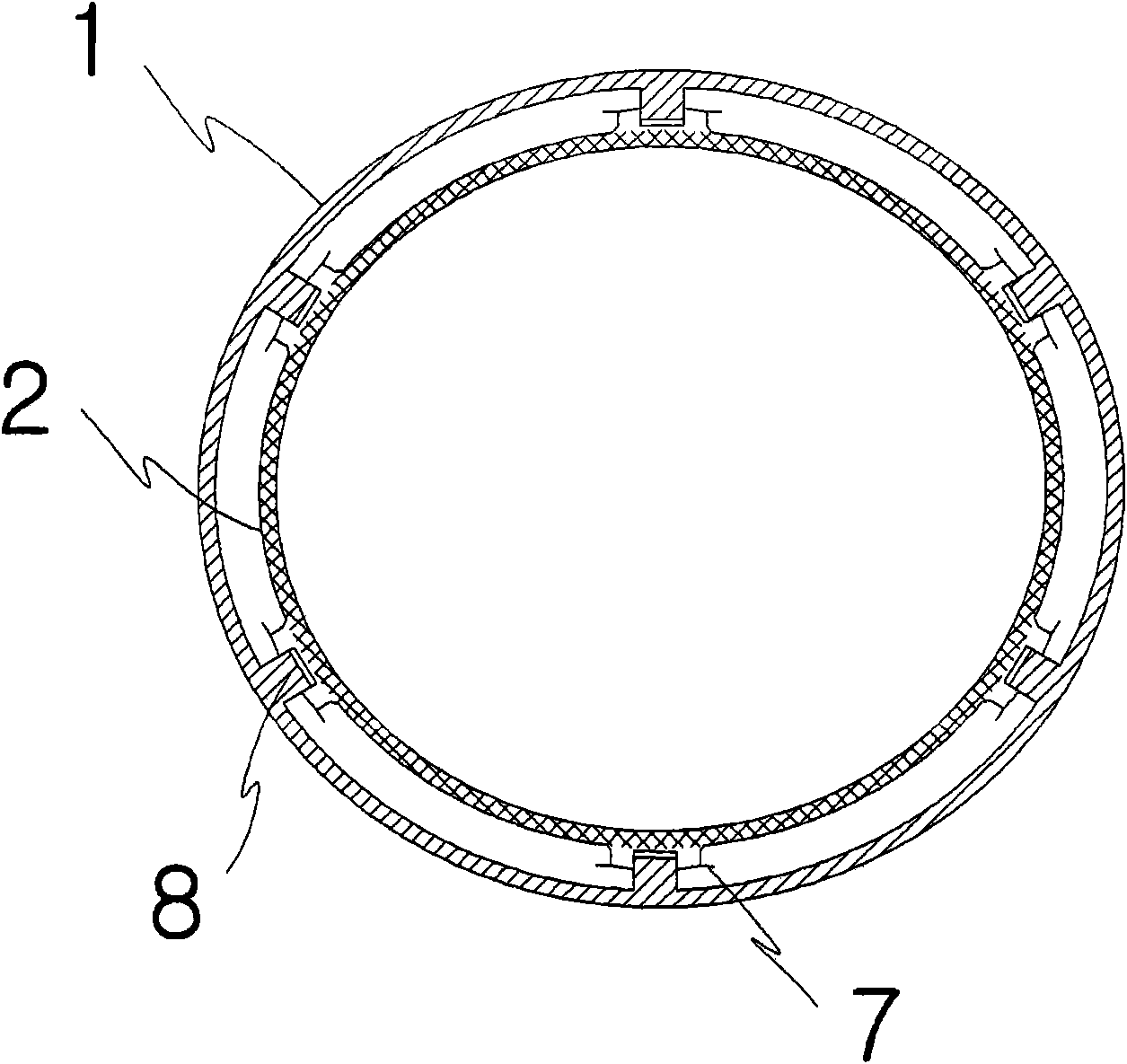

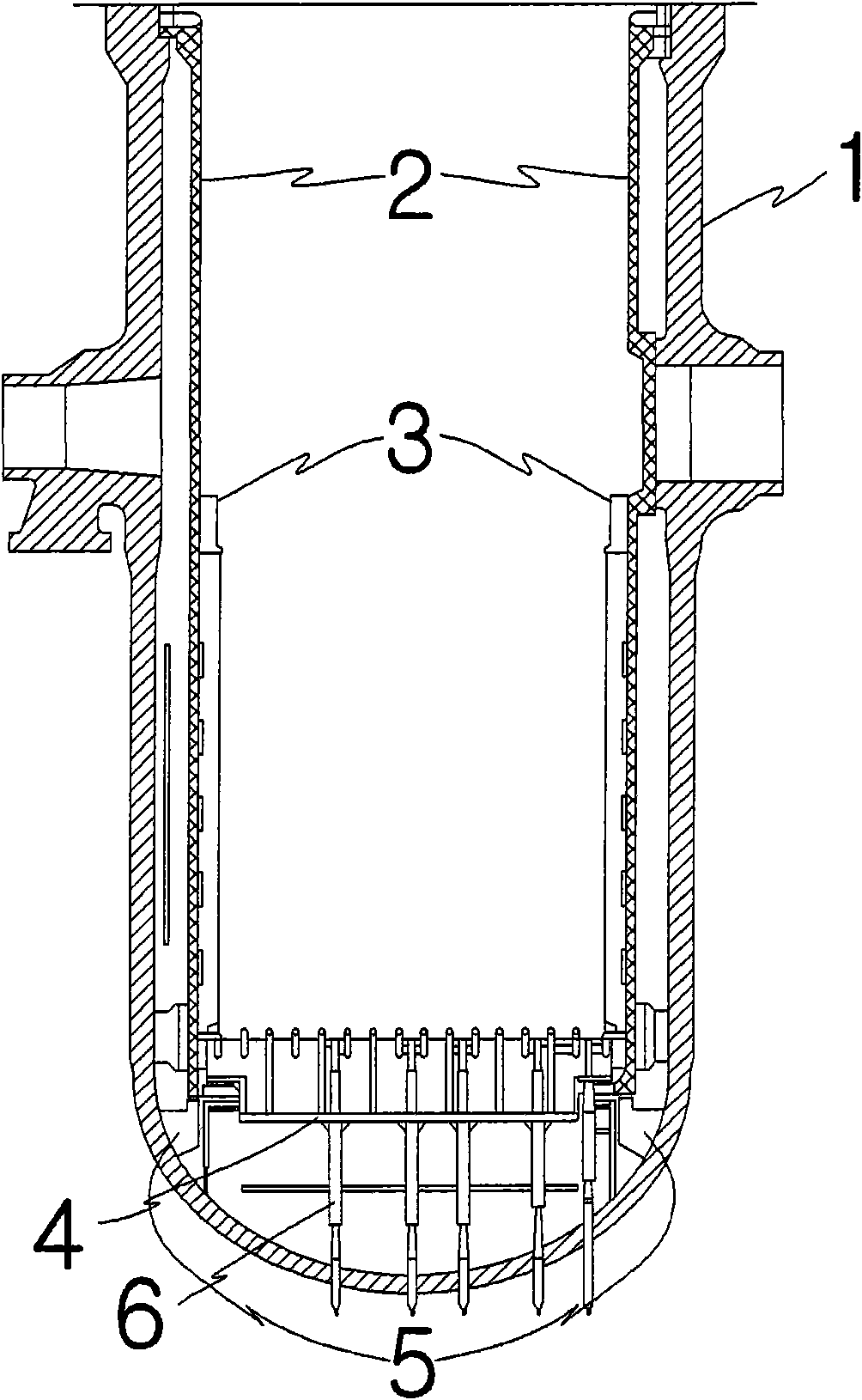

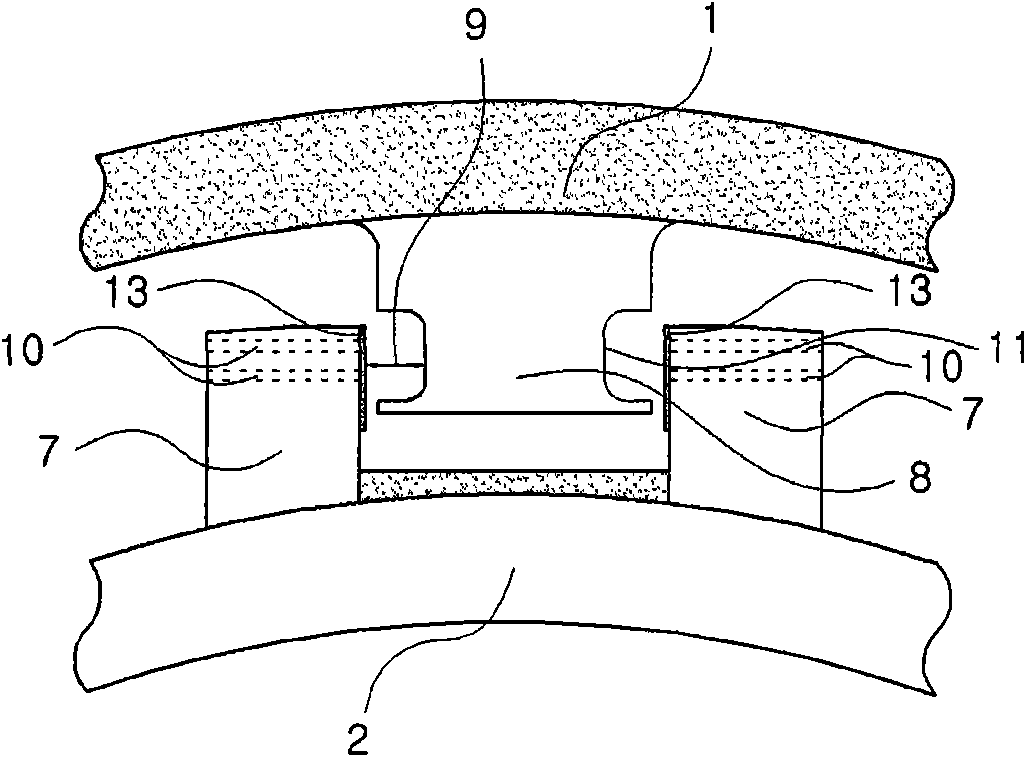

[0048] Hereinafter, preferred embodiments of the remote and precise gap measuring device according to the present invention will be described in detail with reference to the accompanying drawings.

[0049] Figure 4 is a schematic diagram showing said remote, precise gap measurement device according to the present invention, Figure 5 is an assembly drawing showing the gauge block and sensor.

[0050] Such as Figure 4 As shown, the remote, precise gap measurement device includes: a plurality of digital probes 14 for measuring distances, data processing components, air components and power supply components for manipulating the digital probes.

[0051] 4 to 6 digital detectors 14 can be inserted into the core support cylinder protrusion 7 .

[0052] In order to reduce time and cost to effectively measure the gap, it is preferable to insert at least 4 digital detectors 14 into the core support cylinder protrusion 7 .

[0053] Thus, 16 to 24 digital detectors 14 can be conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com