Exhausting separating cleaning apparatus for combine harvester

A technology of combine harvester and cleaning device, which is applied in agricultural machinery and implements, threshing equipment, application, etc., can solve the problems of unsatisfactory cleaning effect, large size of grain cleaning mechanism, and high grain impurity rate, and achieves a simple structure. , The cleaning effect is good, and the grain contains less impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

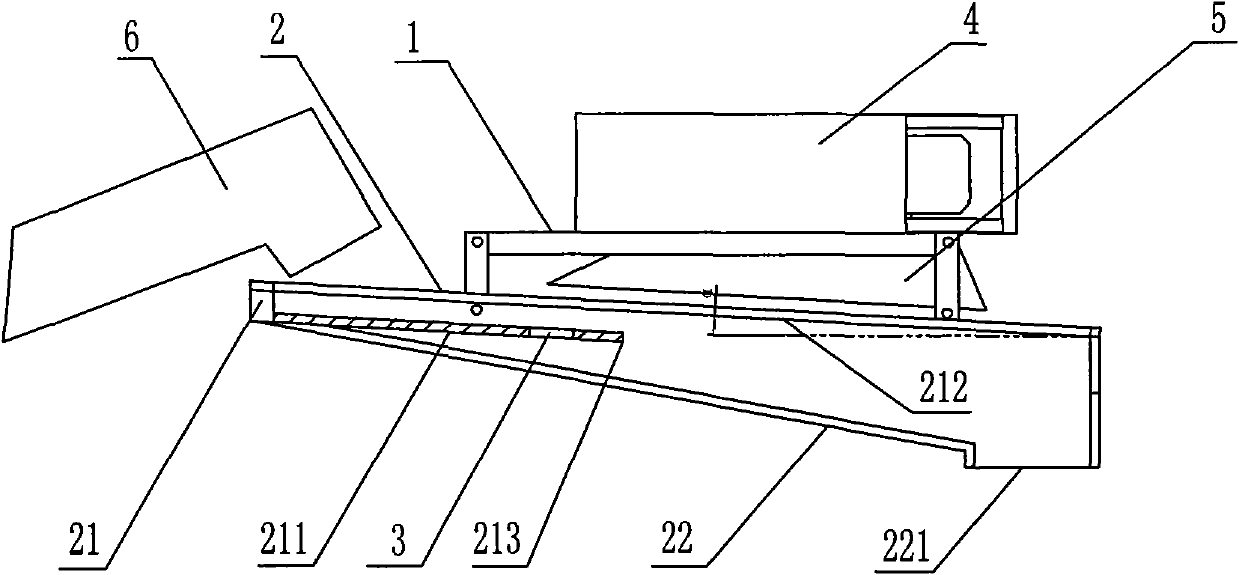

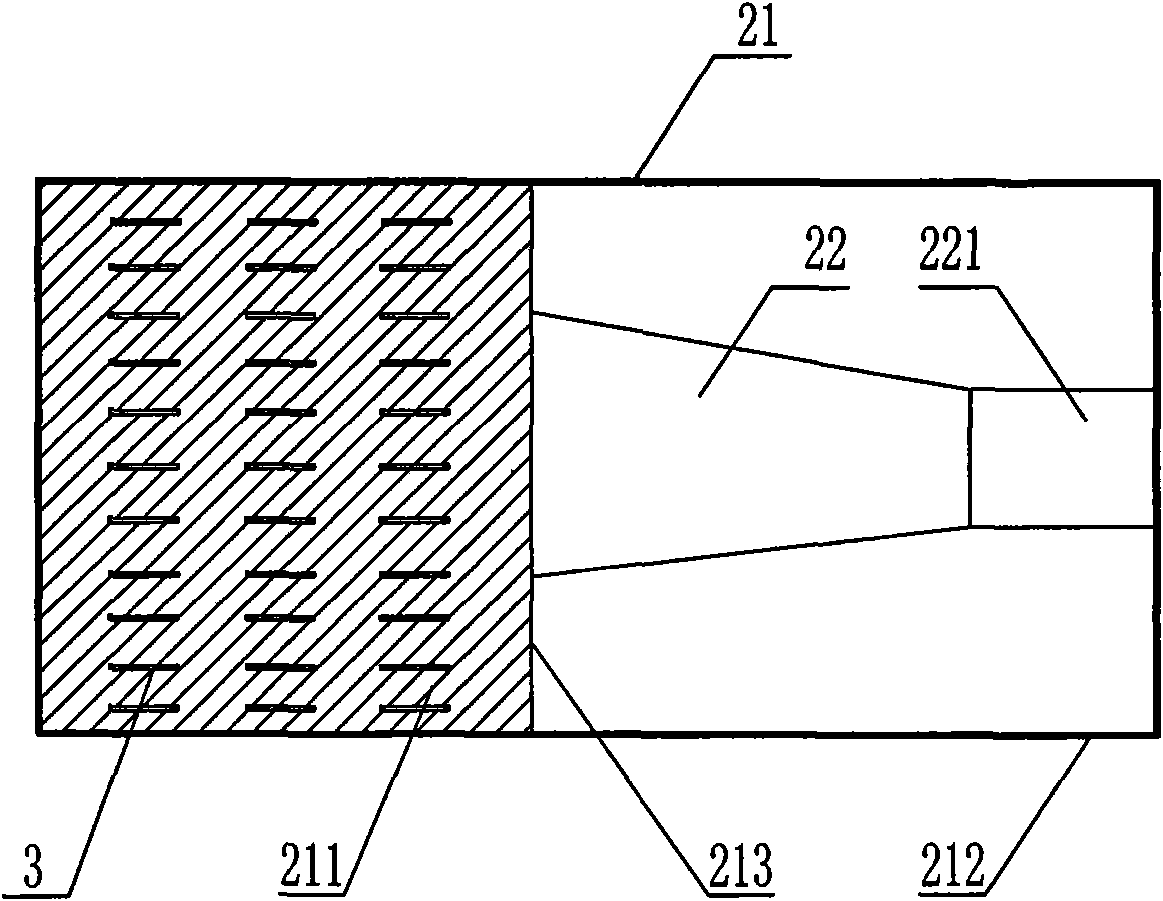

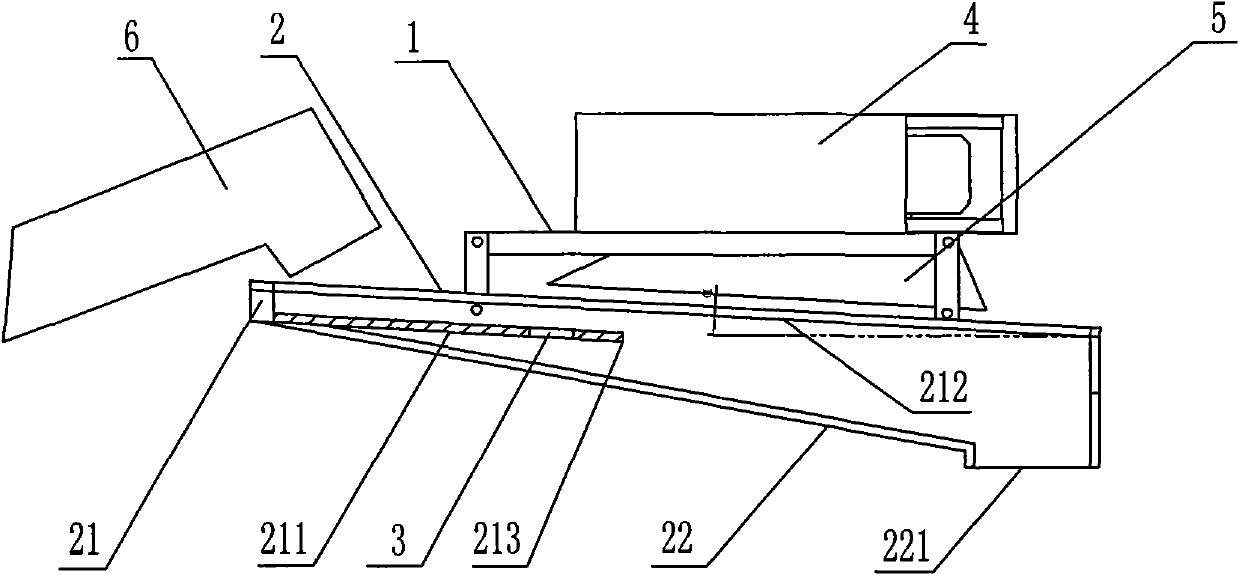

[0012] Below, the present invention will be further described in conjunction with the accompanying drawings.

[0013] figure 1 An embodiment of the present invention is shown, a combined harvester ventilation separation type cleaning device, the sieve 2 is suspended on the frame 1, and is driven by an eccentric wheel mechanism to reciprocate and swing, the sieve 2 includes a sieve body 21 and a grain collection bin 22 , the bottom of the grain collection bin 22 is provided with a grain outlet 221, and the sieve body 21 includes a sieve bottom plate 211 and a square frame baffle plate 212. The wind cover 5 and the sieve bottom plate 211 are evenly distributed with sieve holes 3, the rear section of the sieve 2 is inclined downward, and the angle a between the square frame baffle plate 212 and the horizontal line is 3°.

[0014] The rear part of the sieve 1 is inclined downwards, and the grain materials in the threshing bin and the conveying mechanism 6 fall onto the sieve bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com