Continuous reverse flow extracting tank

A countercurrent extraction and extraction technology, which is applied in the direction of solid solvent extraction, etc., can solve the problems of too large differences in shape and plant layout, the operation platform and plant buildings are overthrown and rebuilt, and the cost is expensive, so as to improve the quality of production environment and cleaning quality Reliable, energy-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

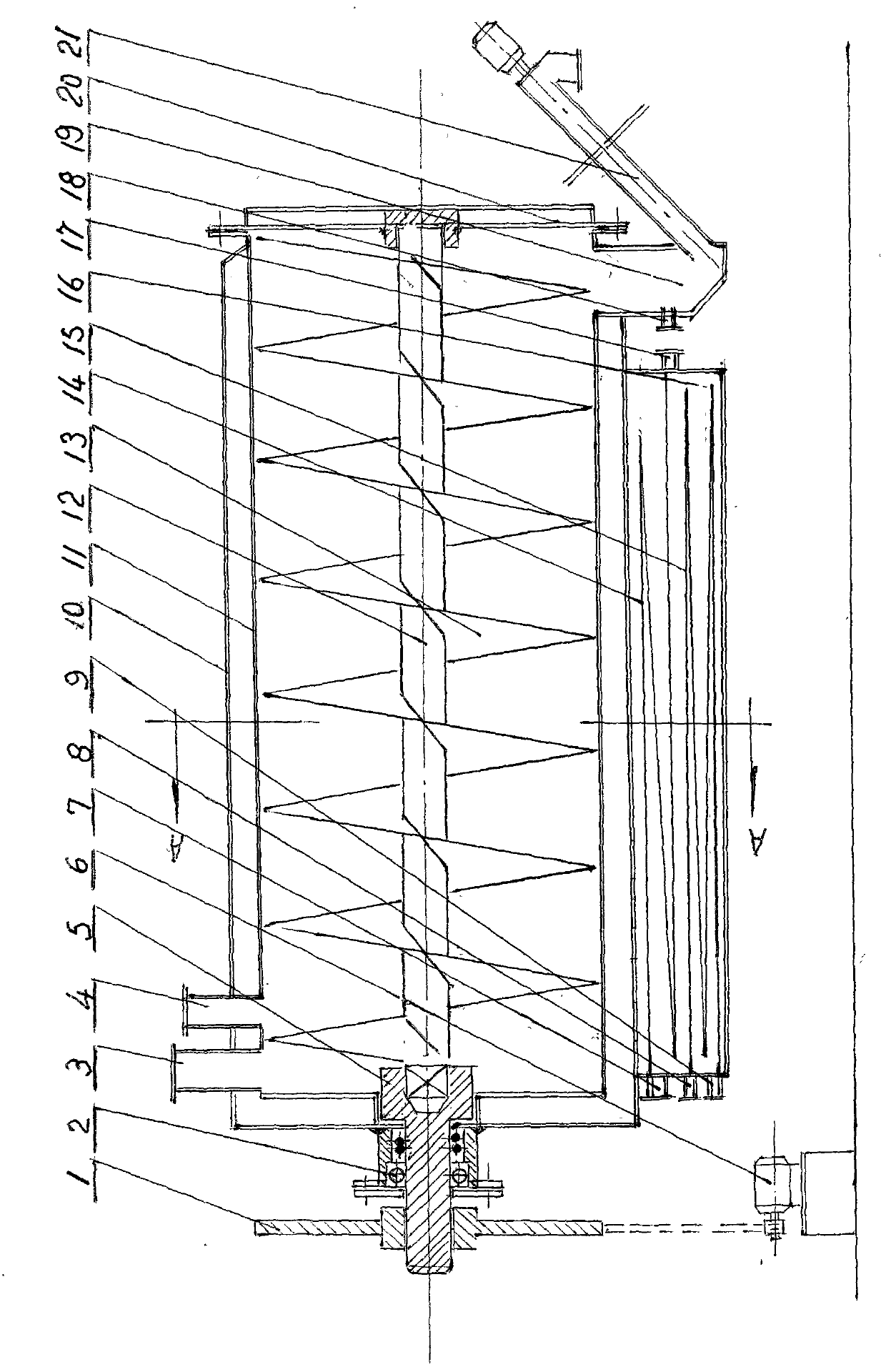

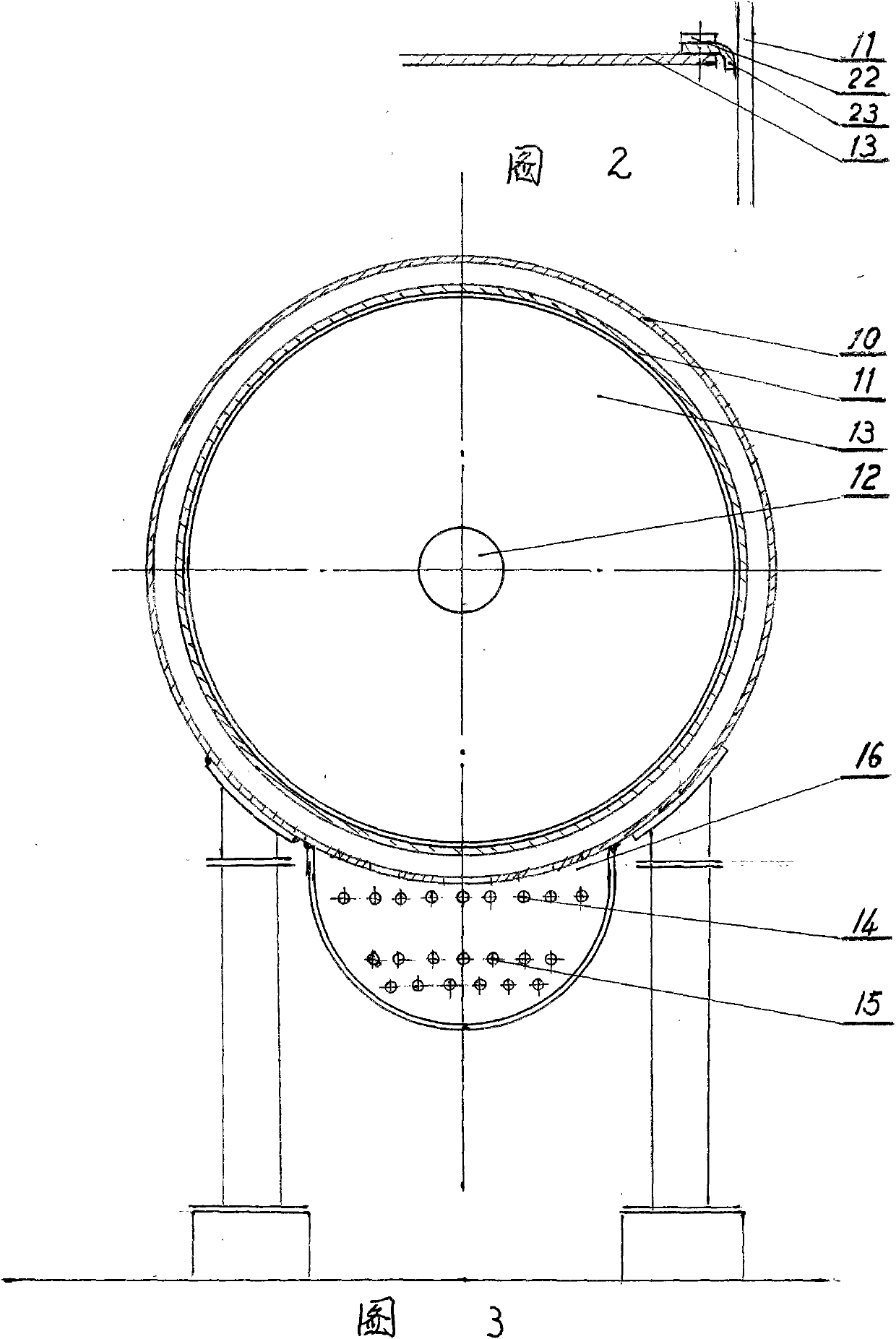

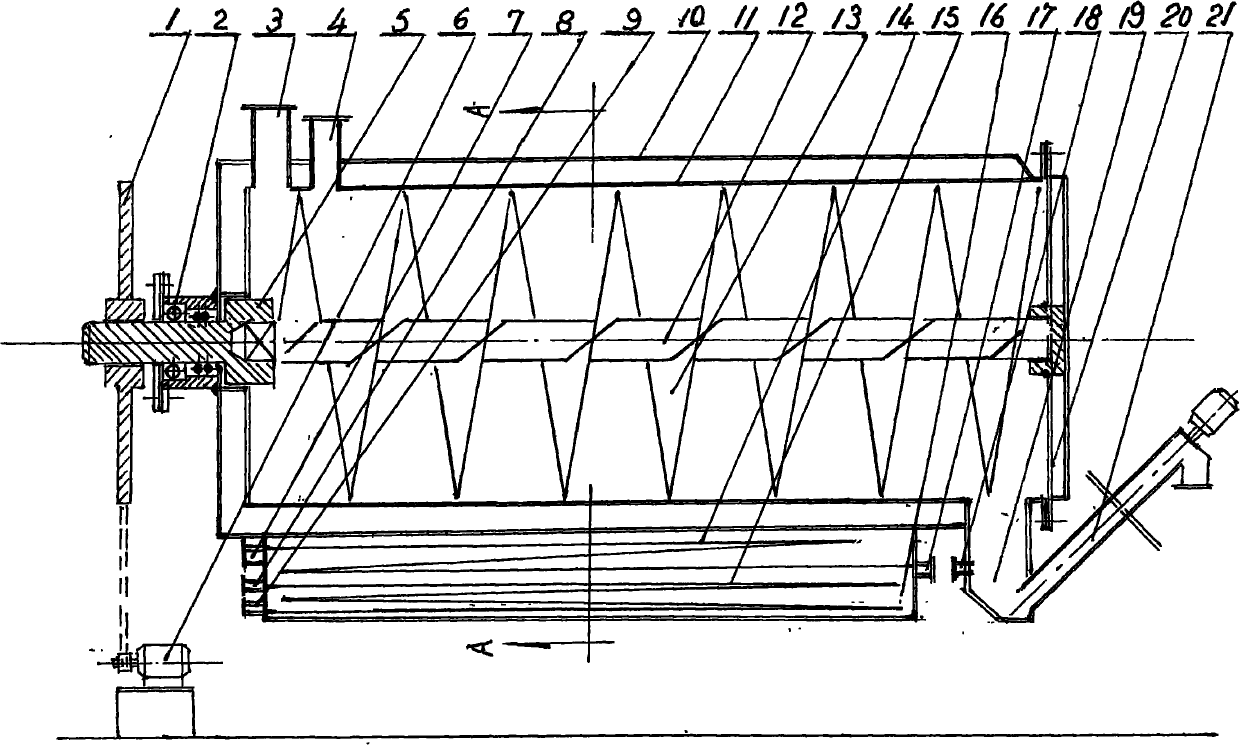

[0009] Embodiments of the present invention will be further described in conjunction with the accompanying drawings, as figure 1 , as shown in 3, the continuous countercurrent extraction tank consists of a sprocket (1), a shaft seal seat (2), a medicinal material inlet (3), an extraction liquid outlet (4), a belt bearing socket drive shaft (5), a driving machine ( 6), solvent inlet (7), heating steam inlet (8), condensate outlet (9), heating jacket (10), horizontal cylinder (11), pushing screw shaft (12), pushing screw ( 13), solvent preheating coil (14), heating evaporation coil (15), low temperature steam generator (16), preheating solvent outlet (17), preheating solvent inlet (18), waste residue tank (19), It is composed of a bearing seat cover plate (20) and a screw slag discharger (21). Its characteristics are: one end of the pusher screw shaft (12) with a square body is inserted into the driving shaft (5) of the belt bearing socket, and the other end is supported on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com