Electromagnetic vibrator

An electromagnetic vibrator and electromagnet technology, which is applied in vibrating conveyors, instruments, automatic packaging control, etc., can solve the problems of manual feeding and low precision, and achieve the effects of simple operation, overcoming low precision, and improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

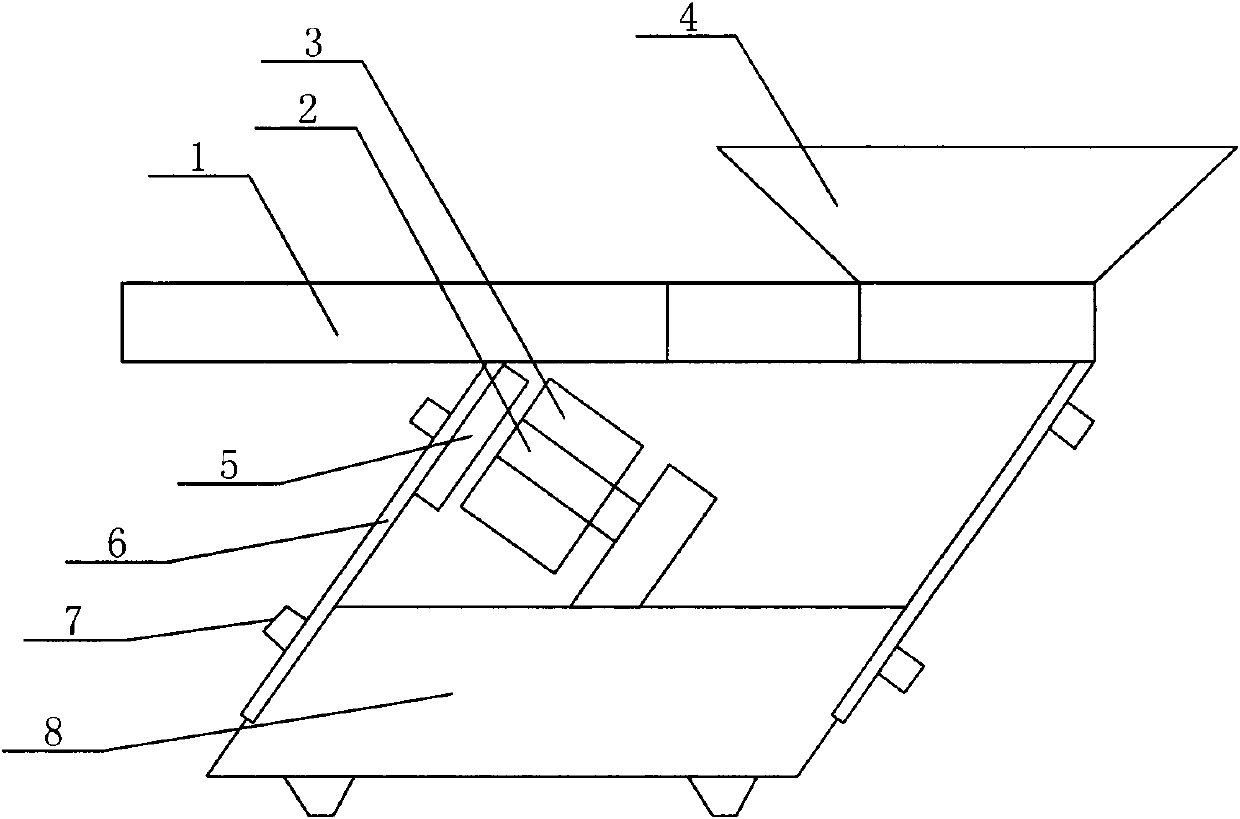

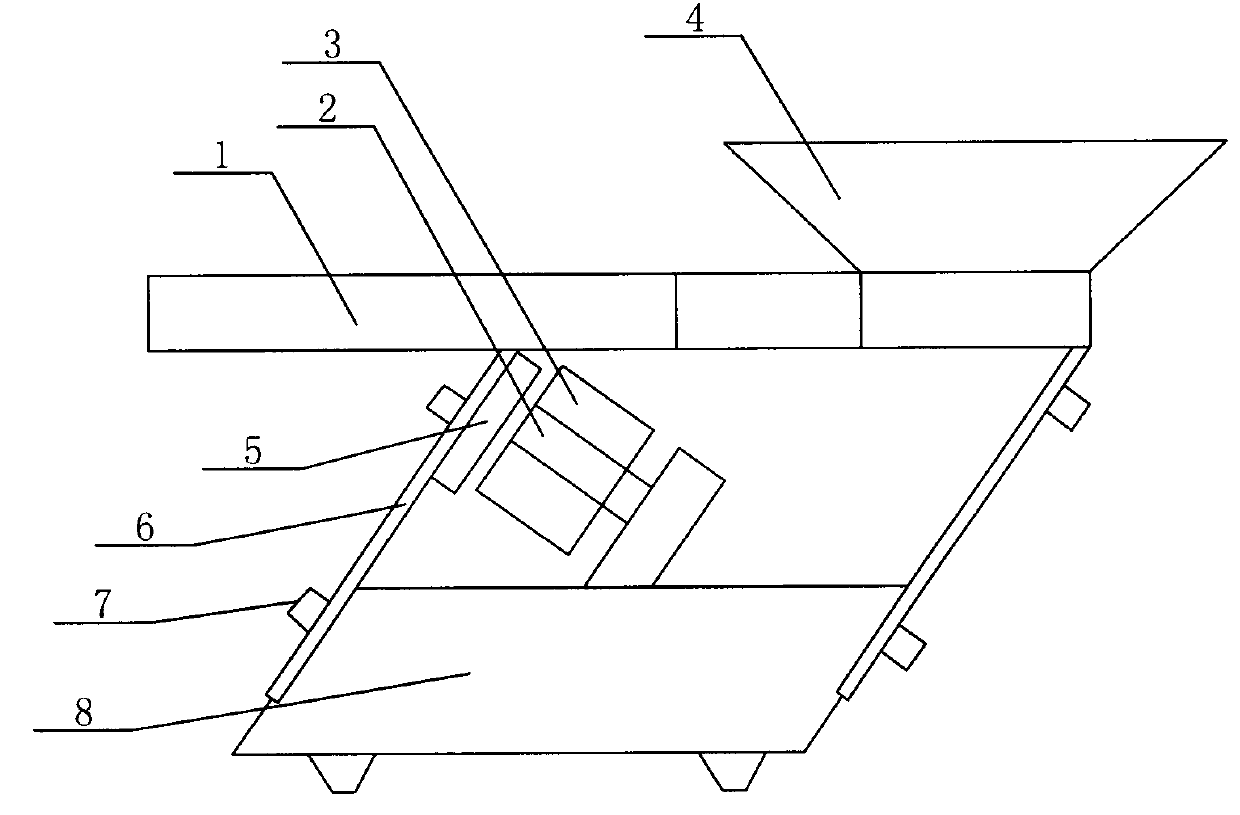

[0008] refer to figure 1 , the specific embodiment adopts the following technical scheme: it is composed of feeding chute 1, electromagnet 2, coil 3, hopper 4, armature 5, leaf spring 6, nut 7 and machine base 8, and feeding chute 1 is arranged on the machine The upper end of the seat 8, the hopper 4 is arranged on the upper right side of the feeding trough 1, the nut 7 is evenly arranged on the outside of the leaf spring 6, the leaf spring 6 is arranged on both sides of the machine base 8, and the armature 5 is arranged on the left side of the leaf spring 6. Inside, the electromagnet 2 and the coil 3 are fixed inside the base 8 .

[0009] The reciprocating motion of the feeding trough 1 is realized by the generation and disappearance of the pulse attraction between the electromagnet 2 and the armature 5 . The present invention is connected with an automatic control circuit, and firstly sets weighing fixed value, feeding speed, etc., and starts the system. Next, the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com