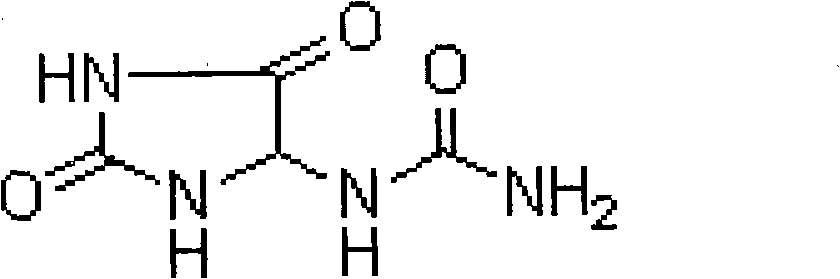

Method for preparing allantoin from nitraria core residue

A technology of Nitraria japonica and allantoin, applied in the direction of organic chemistry, etc., to achieve the effect of simple preparation method and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1: Get 10Kg Nitraria fruit stone residue, add 40% ethanol to extract, its solid-liquid weight ratio is 1: 5, extraction temperature is 80 ℃, extracts 3 times, extraction time 2h; In the ethanol recovery device, recover ethanol at a temperature of 80°C and normal pressure to obtain a paste-like concentrate; then add water to completely disperse the paste-like concentrate, and then add petroleum ether according to 3 times the volume of the paste-like concentrate. Extraction under pressure for 40min, extraction 3 times; after 75μm silica gel column chromatography, and eluting with 20% ethanol, the eluate was heated to 50°C to crystallize, centrifuged, and washed once with water, and the crystals were placed in a constant temperature drying oven Heated to 50°C and dried for 6 hours to obtain 62.8g of 96.5% allantoin.

Embodiment 2

[0009] Embodiment 2: get 10kg Nitraria thorn residue, add 50% ethanol to extract, its solid-liquid weight ratio is 1: 10, extraction temperature is 75 ℃, extracts 2 times, extraction time 1.2h; In the ethanol recovery device, recover ethanol at a temperature of 85°C and normal pressure to obtain a paste-like concentrate; then add water to completely disperse the paste-like concentrate, and then add petroleum ether according to 4 times the volume of the paste-like concentrate. Extract under normal pressure for 50min, extract twice; go through 100μm silica gel column chromatography, and elute with 35% ethanol, heat the eluent to 40°C to crystallize, centrifuge, wash twice with water, and put the crystal in a constant temperature drying oven Heated to 60°C and dried for 5 hours to obtain 65g of 97% allantoin.

Embodiment 3

[0010] Embodiment 3: Get 10kg Nitraria thorn residue, add 60% ethanol to extract, its solid-liquid weight ratio is 1: 15, extraction temperature is 60 ℃, extraction 1 time, extraction time 1h; In the ethanol recovery device, recover ethanol at a temperature of 90°C under normal pressure to obtain a paste-like concentrate; then add water to completely disperse the paste-like concentrate, then add petroleum ether according to 5 times the volume of the paste-like concentrate. Extract under pressure for 60 min, extract once; after 150 μm silica gel column chromatography, and elute with 50% ethanol, heat the eluent to 30°C to crystallize, centrifuge, wash with water for 3 times, and store the crystal in a constant temperature drying oven Heated to 70°C and dried for 6 hours to obtain 63g of 96.8% allantoin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com