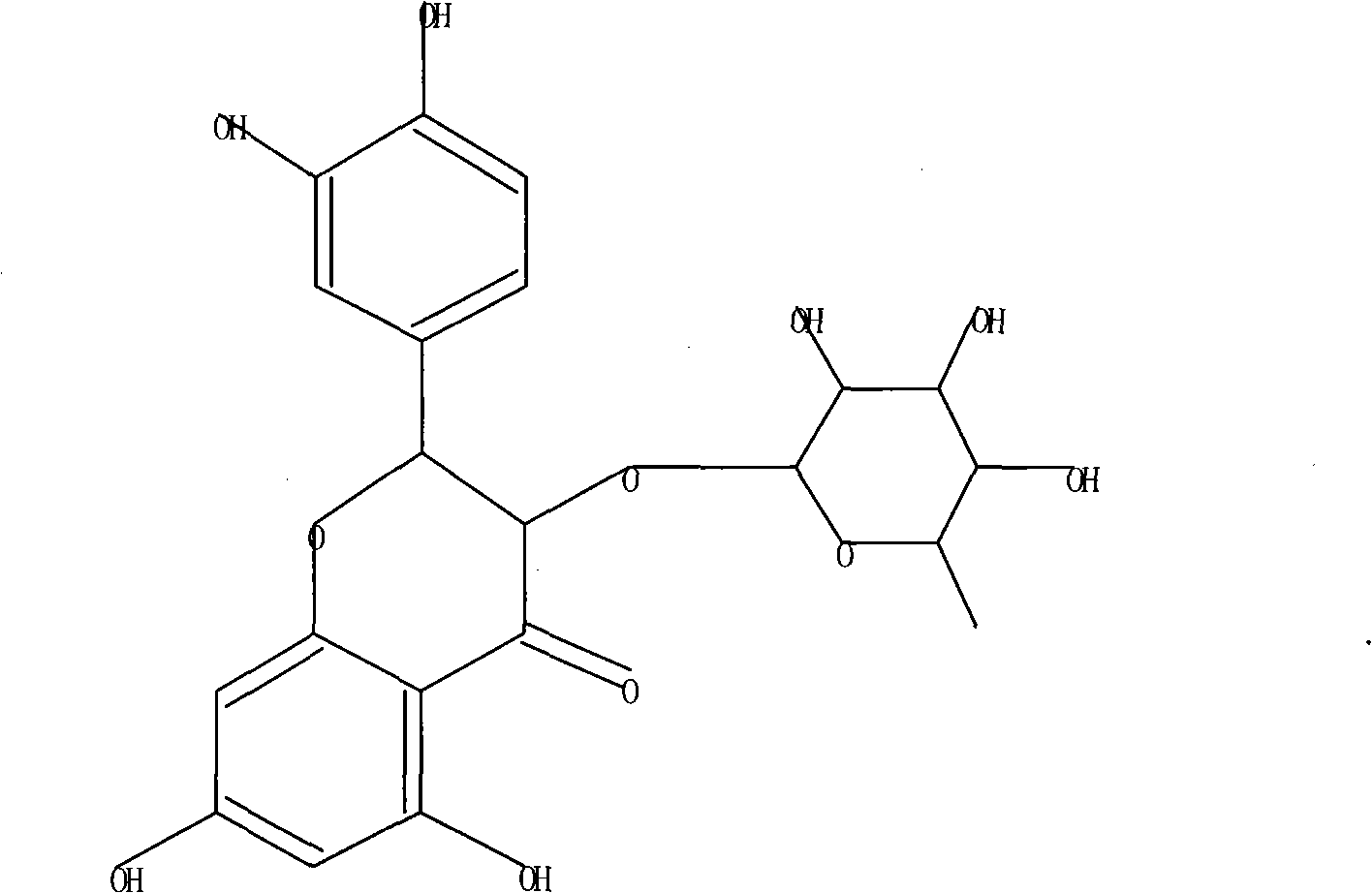

Preparation method of astilbin

A technology for astilbin and extraction is applied in the field of preparation of astilbin to achieve the effects of being beneficial to large-scale production operations, with less pollution and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 10Kg of grape pomace (containing pericarp and seeds), add 30L of 70% ethanol and put it into a microwave extraction device for microwave extraction. The extraction power is 300W, extract once for 5 minutes, collect the extract, filter, recover the ethanol under reduced pressure and concentrate , to obtain the extract, carry out 3-stage countercurrent extraction with a mixed solvent of ethyl acetate-water with a ratio of 8:1, the volume ratio of the extract to the total amount of the mixed solvent is 1:3, combine the extract, recover the solvent under reduced pressure, add Adsorbed with H-50 macroporous adsorption resin, eluted with 50% ethanol, collected 3 times the column volume eluate, recovered the solvent under reduced pressure and concentrated, added ethanol to crystallize, separated cleanly, washed and dried to obtain yellow needle crystals- Astilbin 16.8g, detected by HPLC, the purity is 95.3%, UV, IR, MS, 2 HNMR, 13 The data characterizing its physical pro...

Embodiment 2

[0027] Take 10Kg of grape pomace (containing pericarp and seeds), add 60L of 90% ethanol and put it into a microwave extraction device for microwave extraction, extraction power 600W, extraction 3 times, 10 minutes each time, collect the extract, filter, and recover ethanol under reduced pressure and concentrated to obtain an extract, which is subjected to 6-stage countercurrent extraction with a mixed solvent of ethyl acetate-water in a ratio of 8:1, the volume ratio of the extract to the total amount of mixed solvent is 1:6, the extracts are combined, and the solvent is recovered under reduced pressure , add CD-180 type macroporous adsorption resin for adsorption, elute with 70% ethanol, collect 8 times the column volume eluate, recover the solvent under reduced pressure and concentrate, add ethanol to crystallize, separate and clean, wash and dry to obtain yellow needles Crystal-astilbin 14.7g, detected by HPLC, the purity is 96.1%, UV, IR, MS, 2 HNMR, 13 The data characte...

Embodiment 3

[0029] Take 10Kg of grape pomace (containing pericarp and seeds), add 50L of 80% ethanol and put it into a microwave extraction device for microwave extraction, extraction power 500W, extraction 2 times, 8 minutes each time, collect the extract, filter, and recover ethanol under reduced pressure and concentrated to obtain an extract, which was subjected to 4-stage countercurrent extraction with a mixed solvent of ethyl acetate-water in a ratio of 8:1, the volume ratio of the extract to the total amount of the mixed solvent was 1:4, the extracts were combined, and the solvent was recovered under reduced pressure , add D101 type macroporous adsorption resin for adsorption, elute with 60% ethanol, collect 5 times the column volume eluate, recover the solvent under reduced pressure and concentrate, add ethanol to crystallize, separate and clean, wash and dry to obtain yellow needle crystals- Astilbin 17.3g, detected by HPLC, the purity is 98.1%, UV, IR, MS, 2 HNMR, 13 The data ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com