Preparation method of acrylic ester oligomer modified aqueous polyurethane pressure-sensitive adhesive

An acrylate-based, water-based polyurethane technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of poor emulsion stability, low monomer conversion rate, and large residual monomer odor. Emulsion stability, high monomer conversion rate, good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

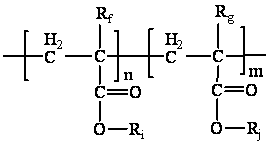

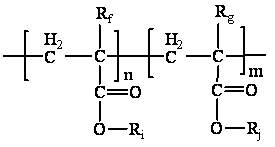

[0034] Example 1: Under the operating conditions of the comparative example, with 0.3g acrylate oligomer (R f = H, R i : n = 4, R g = H, R j : n = 2; the number average molecular weight is about 65000) to replace part of TMP, the reaction time is 1~2h, the polyurethane prepolymer is chemically modified during the prepolymerization process, and the rest of the conditions are the same as the comparative example, and finally the transparent with blue light is obtained The emulsion (theoretical solid content is 30.44%).

Embodiment 2

[0035] Example 2: Under the operating conditions of the comparative example, with 0.5g acrylate oligomer (R f = H, R i : n = 4, R g = H, R j : n = 2; the number average molecular weight is about 45000) to replace part of TMP, the reaction time is 1~2h, and the other conditions are the same as the comparative example, and finally a white translucent emulsion with blue light is obtained (theoretical solid content is 30.83%).

Embodiment 3

[0036] Example 3: Under the operating conditions of the comparative example, adjust the amount of N210 to 7.0g, adjust the amount of 330N to 11.43g, and replace IPDI with 6.0gTDI, react for 1~3h, and get the prepolymer when the NCO value in the system basically reaches the theoretical value (the same as the R value in the comparative example), with 1.0g acrylate oligomer (R f = H, R i : n = 0, R g = CH 3 , R j : n = 2; the number average molecular weight is about 40000) to replace part of TMP, the reaction time is 1~2h, and the other conditions are the same as the comparative example, and finally an opaque yellowish emulsion (theoretical solid content is 31.56%) is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com