Selective catalyst reduction (SCR) urea tank for after-treatment of exhaust gas of diesel engine

A technology of exhaust post-treatment and urea tank, which is applied in the direction of exhaust devices, mechanical equipment, engine components, etc., can solve the problems of high price and complex system, reduce system cost, simplify system structure, improve measurement accuracy and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

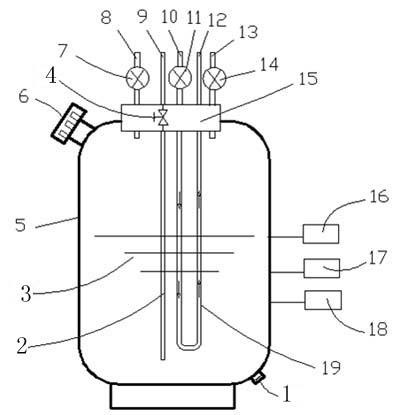

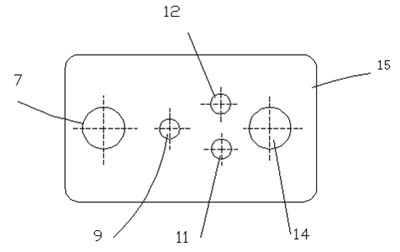

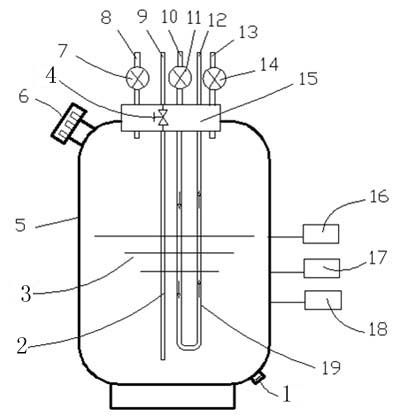

[0009] Below in conjunction with accompanying drawing, the present invention will be further described, as shown in Figure 1, a kind of SCR urea tank that is used for aftertreatment of exhaust gas of diesel engine, comprises tank body 5, valve seat 15, charging solenoid valve 7, urea filling valve 6 , the urea outlet valve 23, the deflation solenoid valve 14, the urea pipe 2 in the tank that is set in the tank, it is characterized in that: the urea tank is a pressure vessel tank, the bearing pressure is 1.0MPa, and the upper end of the urea pipe 2 in the tank body 5 is fixed on The urea outlet valve 4 is connected to the urea outlet pipe 9, and the valve seat 15 is also equipped with a temperature sensor 17, a liquid level sensor 16, a heating pipe 19, and a pressure sensor 18, and a discharge port 1 is installed at the bottom of the urea tank.

[0010] The urea solution in the tank body 5 is kept at about 0.8 MPa under the action of air pressure, and the pressure in the urea t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com