Control system and method of air compressor unit

A technology of air compressor unit and control system, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of shortened life of air compressor and frequent start and stop of air compressor, so as to improve the service life and solve frequent problems The effect of start-stop and stable supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

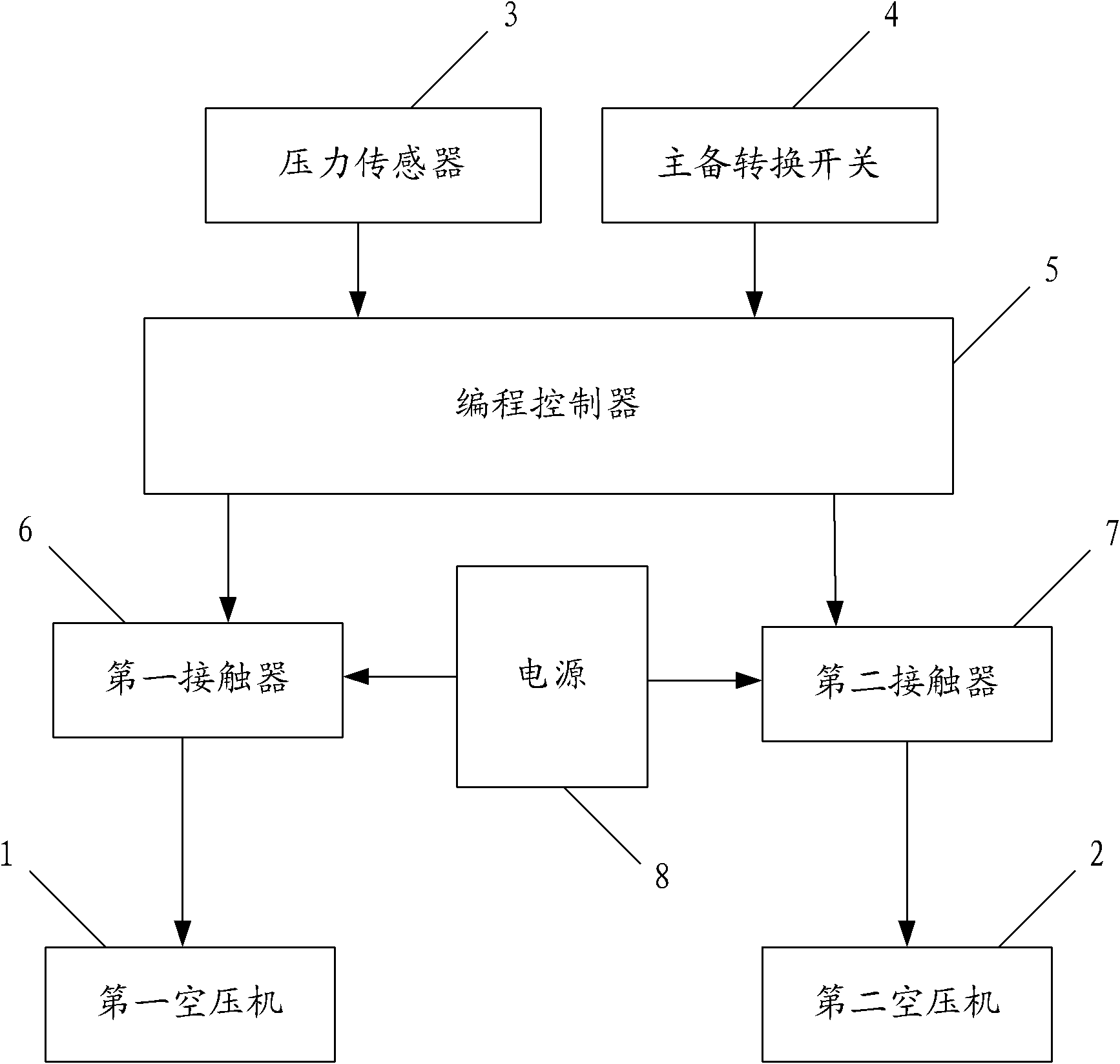

[0042] figure 1 This is a schematic structural diagram of an air compressor control system provided in an embodiment of this application.

[0043] Such as figure 1 As shown, the air compressor unit in the embodiment of the present application includes a first air compressor 1 and a second air compressor 2. The two air compressors are in a standby relationship with each other. The air compressor control system includes: a pressure sensor 3. Main / standby switch 4, programming controller 5, first contactor 6 and second contactor 7, in which: the first air compressor 1 is connected to the power supply 8 through the first contactor 6, and the second air compressor 2 is connected to the power supply 8 through the second contactor 7, the pressure sensor 3 and the main-standby switch 4 are connected to the programming controller 5, and the programming controller 5 is also connected to the first contactor 6 and the second contactor 7 respectively .

[0044] The pressure sensor 3 is install...

Embodiment 2

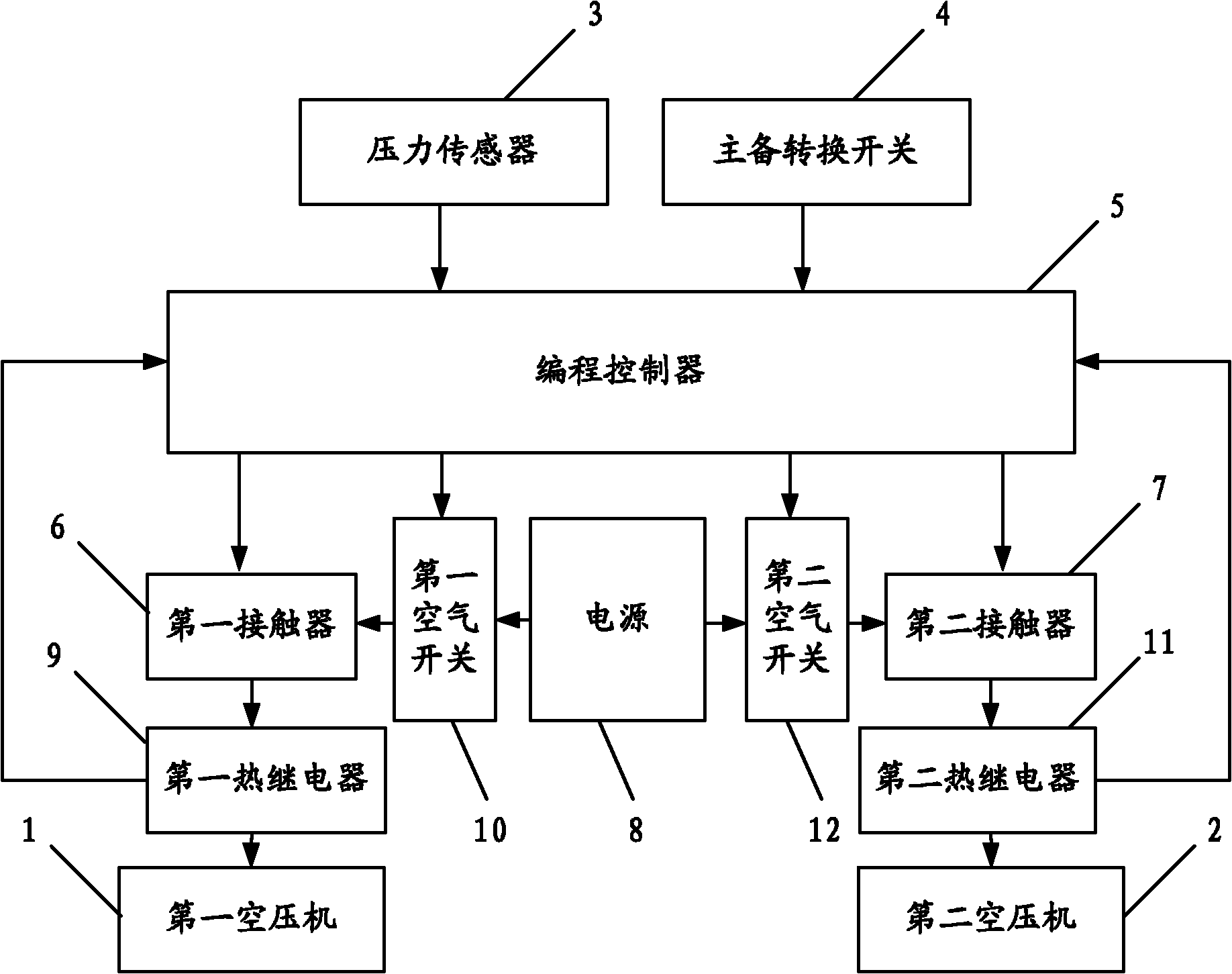

[0052] figure 2 This is a schematic structural diagram of another air compressor control system provided in an embodiment of this application.

[0053] In order to improve the avoidance of the air compressor being damaged due to overload during the operation process, thereby affecting the safety of the system operation, in the embodiment of the present application, the system may further include: a first thermal relay 9 and a first air switch 10 for Carry out overload protection for the first air compressor 1, where:

[0054] The first thermal relay 9 is connected between the first air compressor 1 and the first contactor 6, and is also connected to the programming controller 5 for detecting the input current of the first air compressor 1 and sending the overload current signal Send to programming controller 5;

[0055] The first air switch 10 is connected between the first contactor 6 and the power supply 8, and is connected to the programming controller 5. The programming control...

Embodiment 3

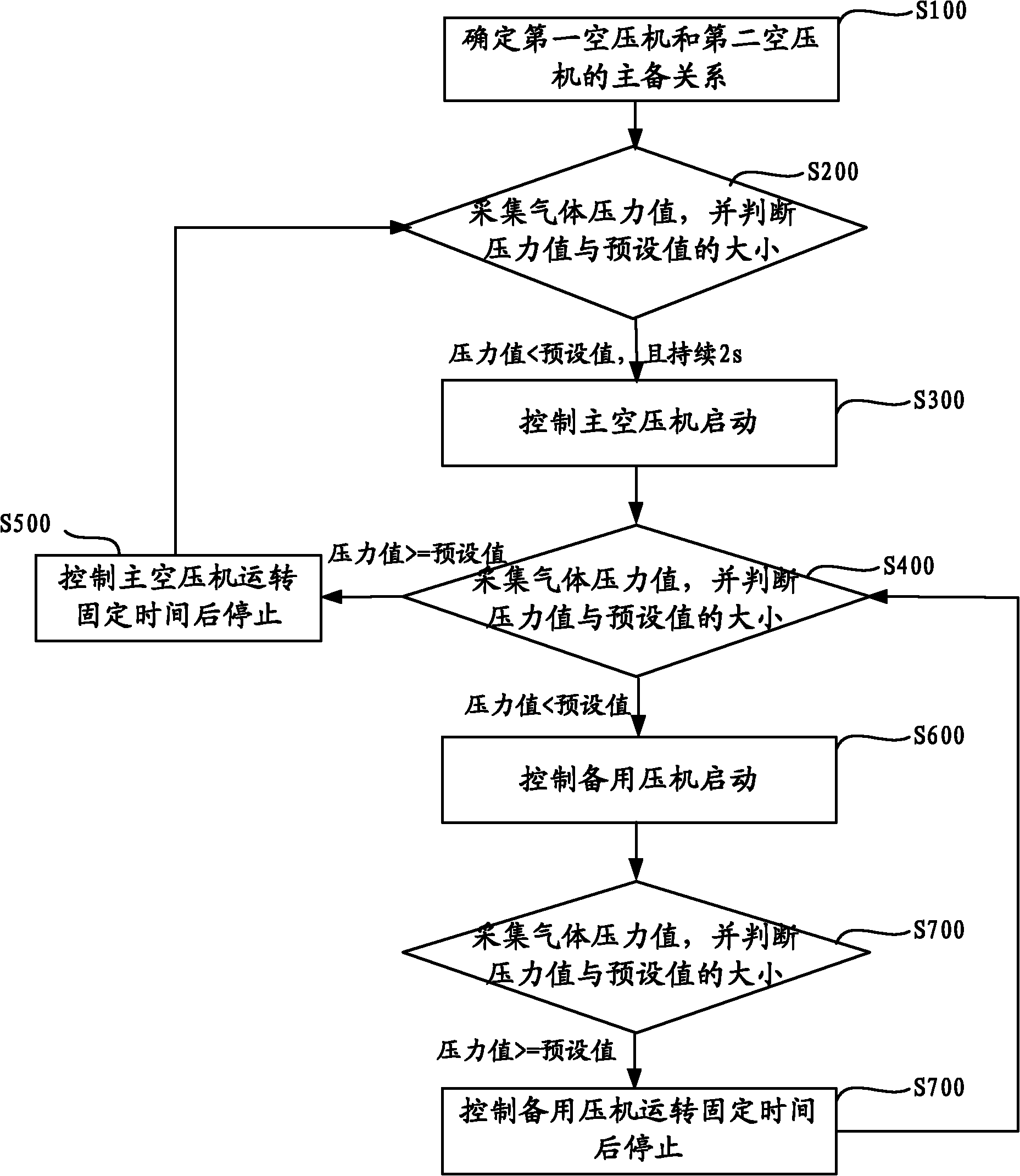

[0060] On the basis of the system provided in the first embodiment, the embodiment of this application also provides an air compressor control method, such as image 3 As shown, the flow diagram of an air compressor control method provided by an embodiment of this application.

[0061] Such as image 3 As shown, the method includes:

[0062] Step S100: Determine the main-standby relationship between the first air compressor and the second air compressor;

[0063] Step S200: Collect the pressure value of the gas inside the gas pipeline, and determine the magnitude of the pressure value and the preset value;

[0064] The collected pressure value is related to the gas transmission volume inside the gas pipeline, and the following operations are performed according to the judgment result: if the pressure value is greater than or equal to the preset value, step S200 is repeated; if the pressure value is lower than the preset value Set the value and continue for 2 seconds, then proceed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com