Optical fiber coupling connector

An optical fiber coupling and connector technology, which is applied in the field of embedded optical fiber coupling connectors, can solve problems such as affecting molding efficiency and product yield, difficult to pull out, damage, etc., to improve molding efficiency and product yield, and easy to assemble. , the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

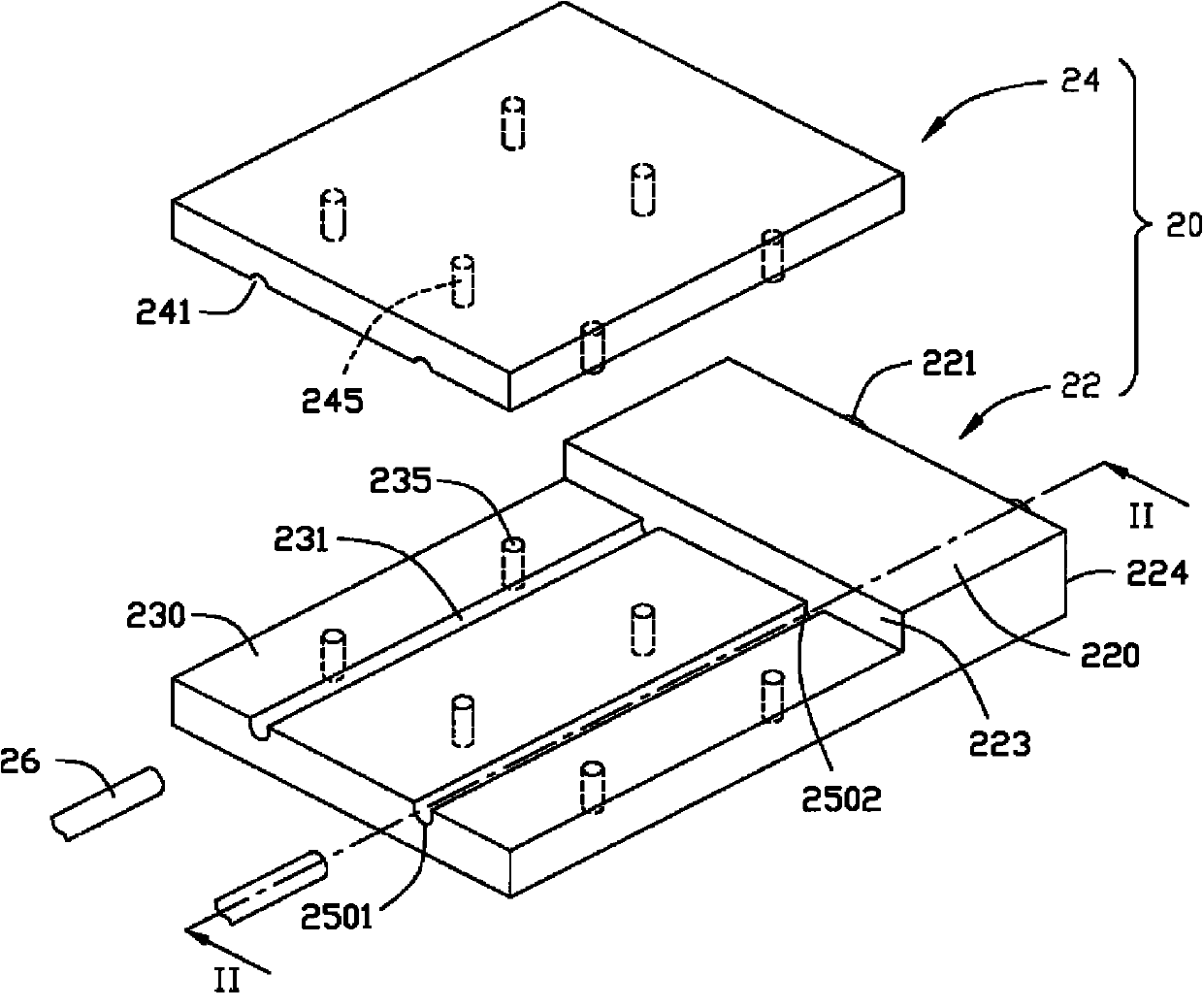

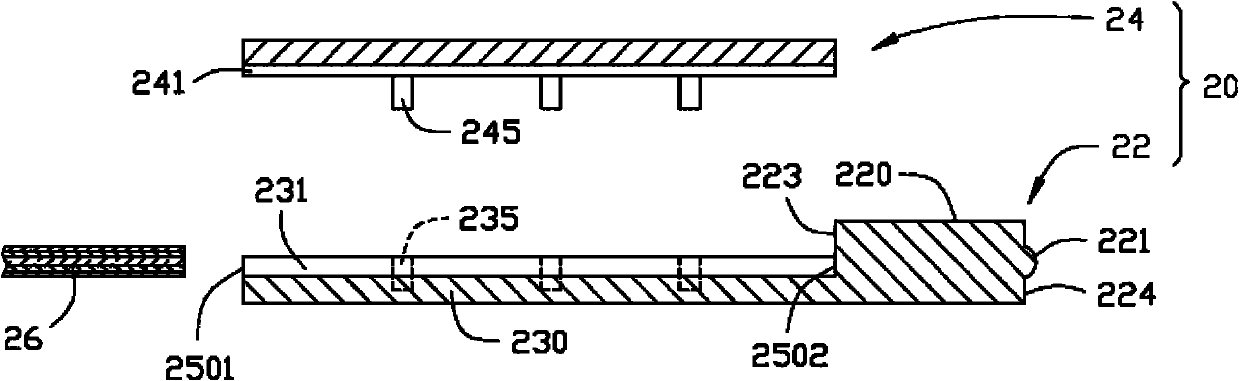

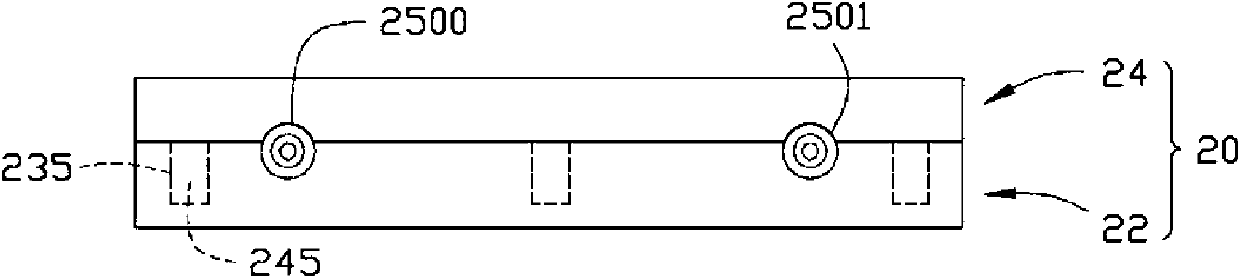

[0013] Please also refer to figure 1 and figure 2 , the first embodiment of the present invention provides a fiber coupling connector 20 for coupling an optical fiber 26 , which includes a body 22 and a cover 24 that are separated and detachably matched.

[0014] The body 22 has an optical coupling part 220 and a carrying part 230 . The optical coupling part 220 has a light incident surface 223 and a light exit surface 224 . The carrying portion 230 defines a first guiding groove 231 . The cover body 24 defines a second guiding groove 241 corresponding to the first guiding groove 231 .

[0015] Preferably, an optical lens 221 is disposed on the light emitting surface 224 , and the material of the optical lens 221 is the same as that of the optical coupling part 220 . The first guiding groove 231 extends toward the optical lens 221 .

[0016] The cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com