Composite insulator support fixing gap line type arrester

A technology of composite insulators and fixed gaps, which is applied in the field of lightning arresters, can solve the problems of inconvenient construction on site, large volume, short circuit in the gap, etc., and achieve the effect of convenient installation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

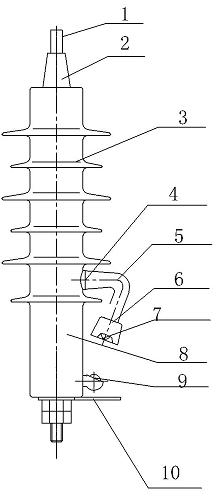

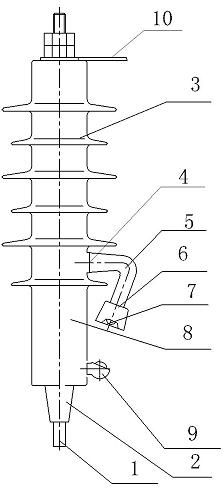

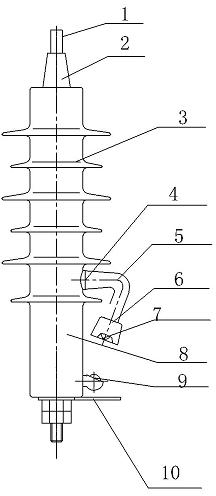

[0016] The composite insulator whose upper end is a high-voltage terminal supports a fixed-gap line-type surge arrester. The structure is as follows: figure 1 As shown, the high-voltage terminal uses a silicone rubber insulating cover 2 to seal the metal terminal, the wire uses a 10kV cross-linked polyethylene insulated conductor 1, the insulating cover 2 is installed on the upper end of the arrester body 3, and the insulated wire 1 is drawn out through the upper end of the insulating cover 2. Composite insulator 8 is installed on the lower part of arrester body 3, and arrester mounting plate 10 is installed on the lower end of composite insulator 8. Composite insulation AC gapless metal oxide arrester and composite insulator 8 are made into one by using latitude-free tape winding process and high-temperature vulcanized silicon rubber process. overall. There is a tap 4 between the arrester body 3 and the composite insulator 8, and the upper discharge electrode 5 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com