Communication system used for underground machinery equipment

A technology for mechanical equipment and communication systems, applied in the field of communication systems, can solve problems such as inconvenience and inconvenience of wiring, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

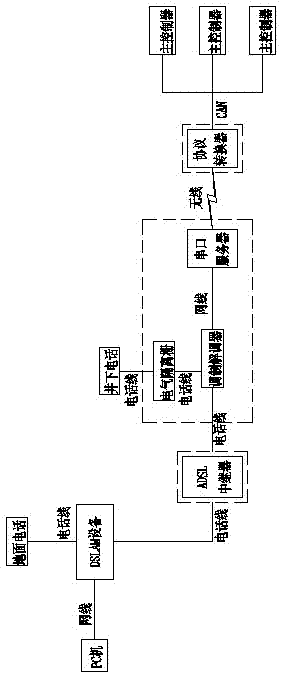

[0021] Embodiment one: see figure 1 As shown, a communication system for underground mechanical equipment includes a wireless transmission part and a wired transmission part. The main controller of each device transmits data to the signal conversion device through the wireless transmission part, and the signal conversion device passes through the wireless transmission part. The wired transmission part is connected with the telephone set and data receiving equipment on the ground;

[0022] The wireless transmission part: includes a protocol converter with a wireless function, the protocol converter is connected with the main controller of each device via the CAN bus, and connected with the serial port server with the wireless data transmission function via the wireless network.

[0023] The wired transmission part: the signal conversion device includes a modem, a serial server with wireless data transmission function and an electrical isolation barrier, the serial server...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com